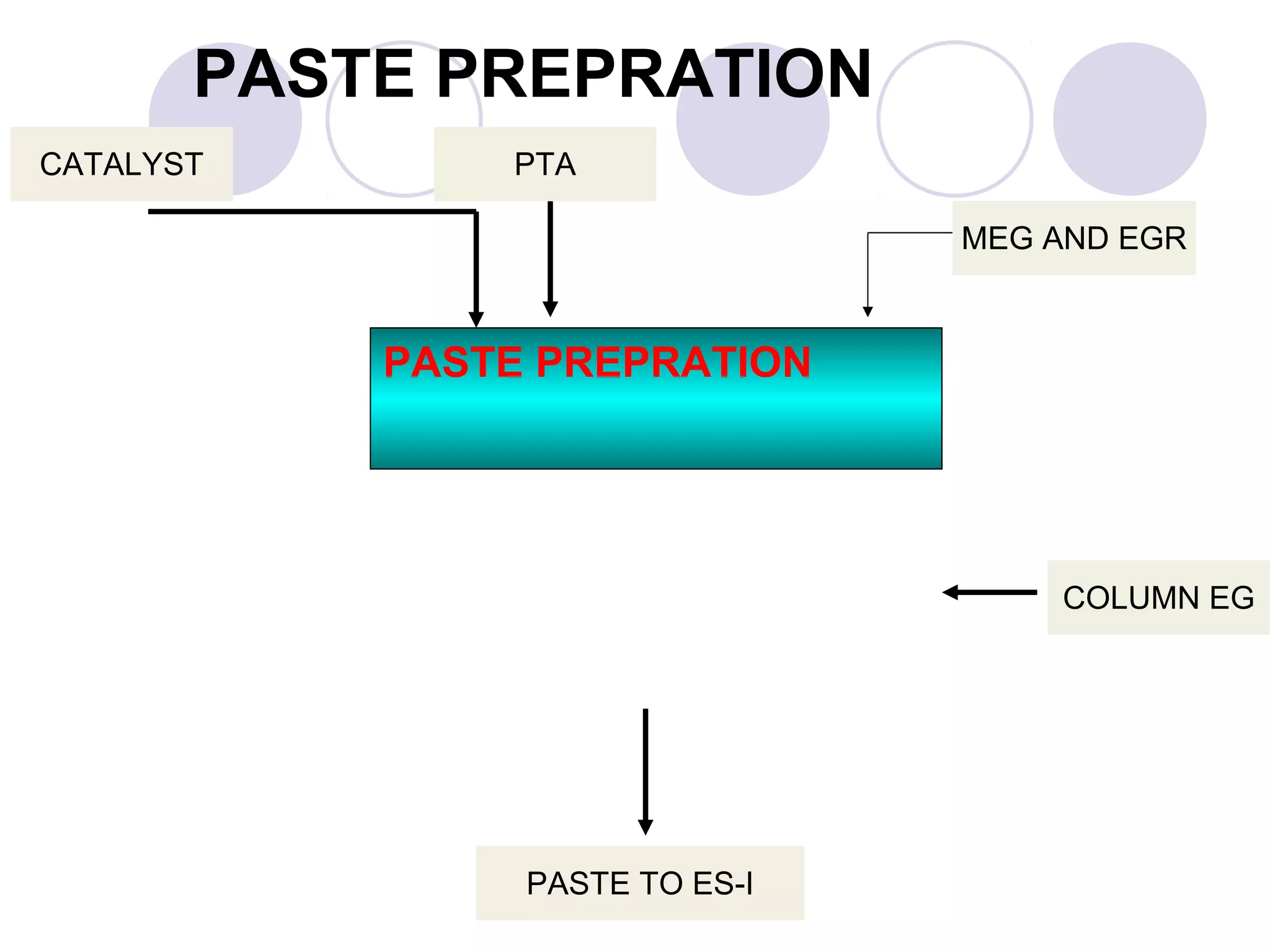

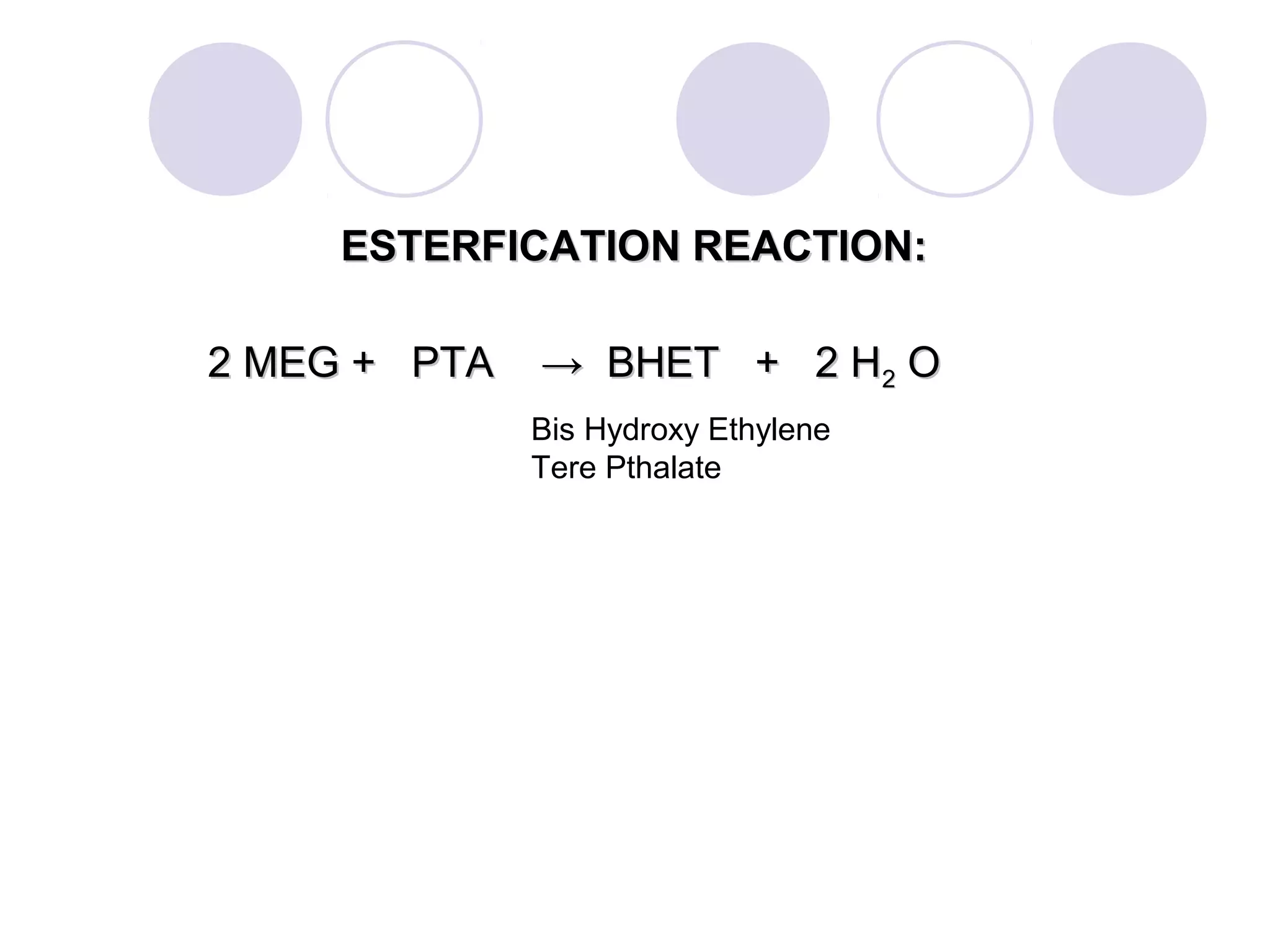

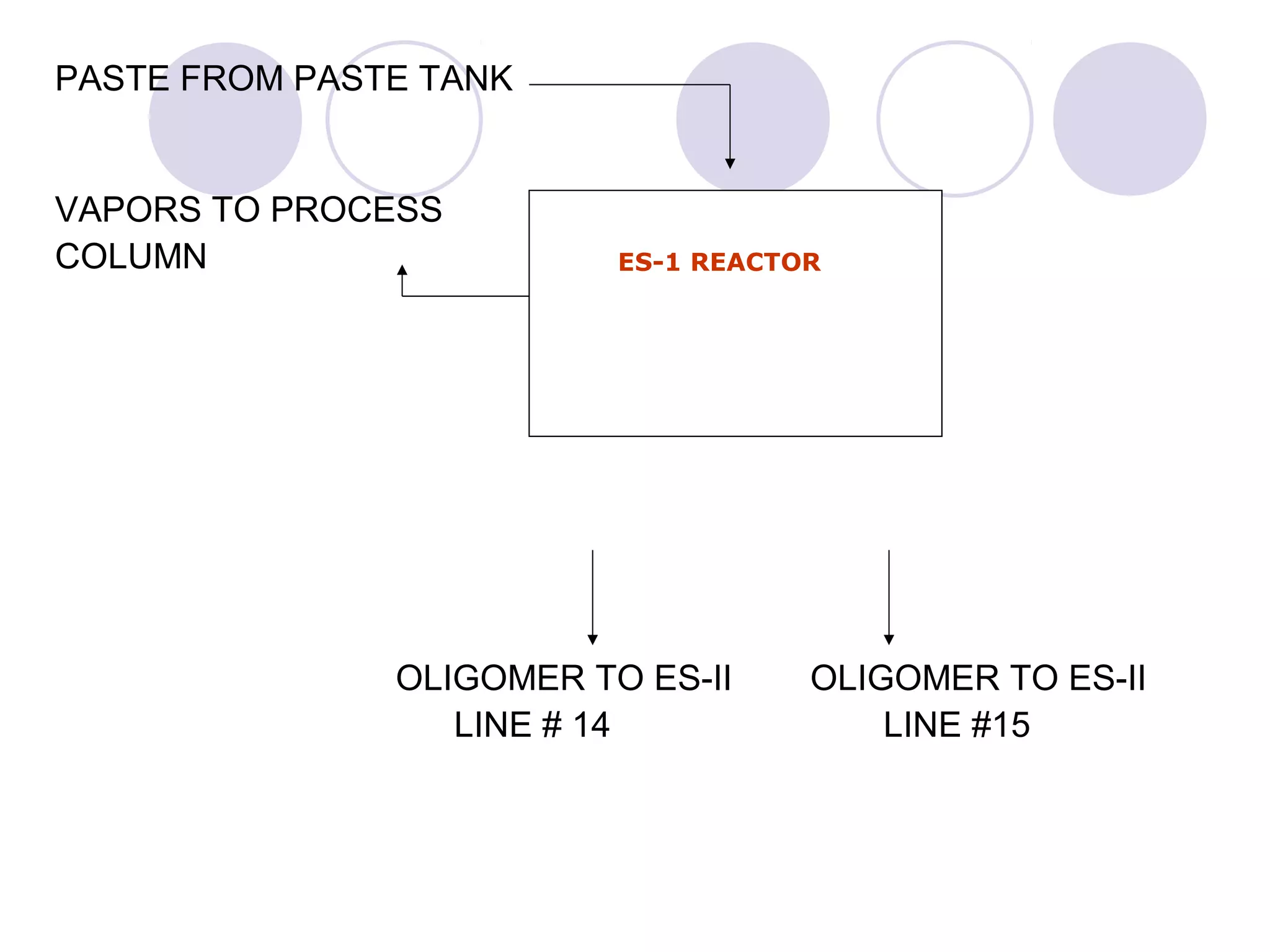

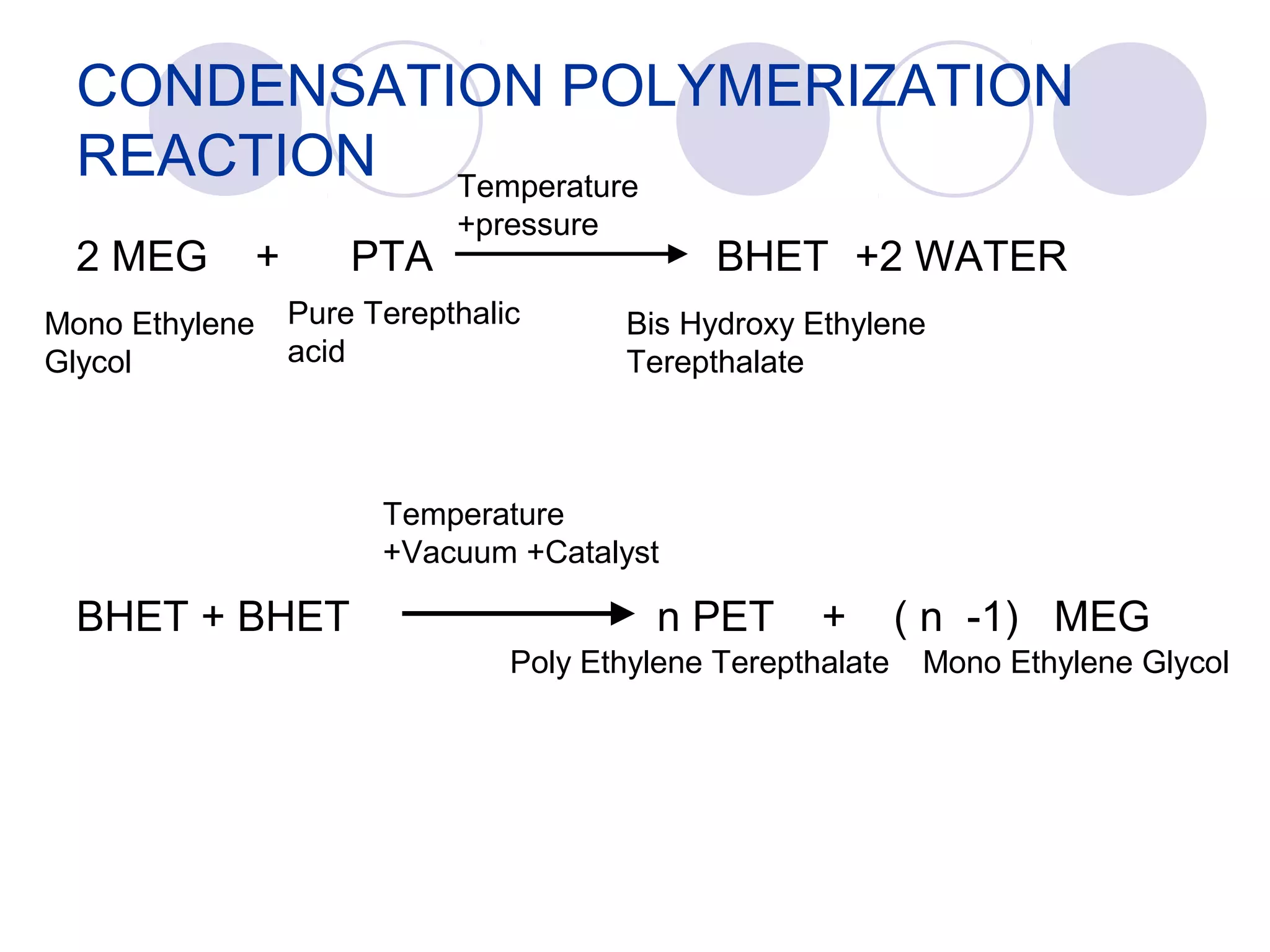

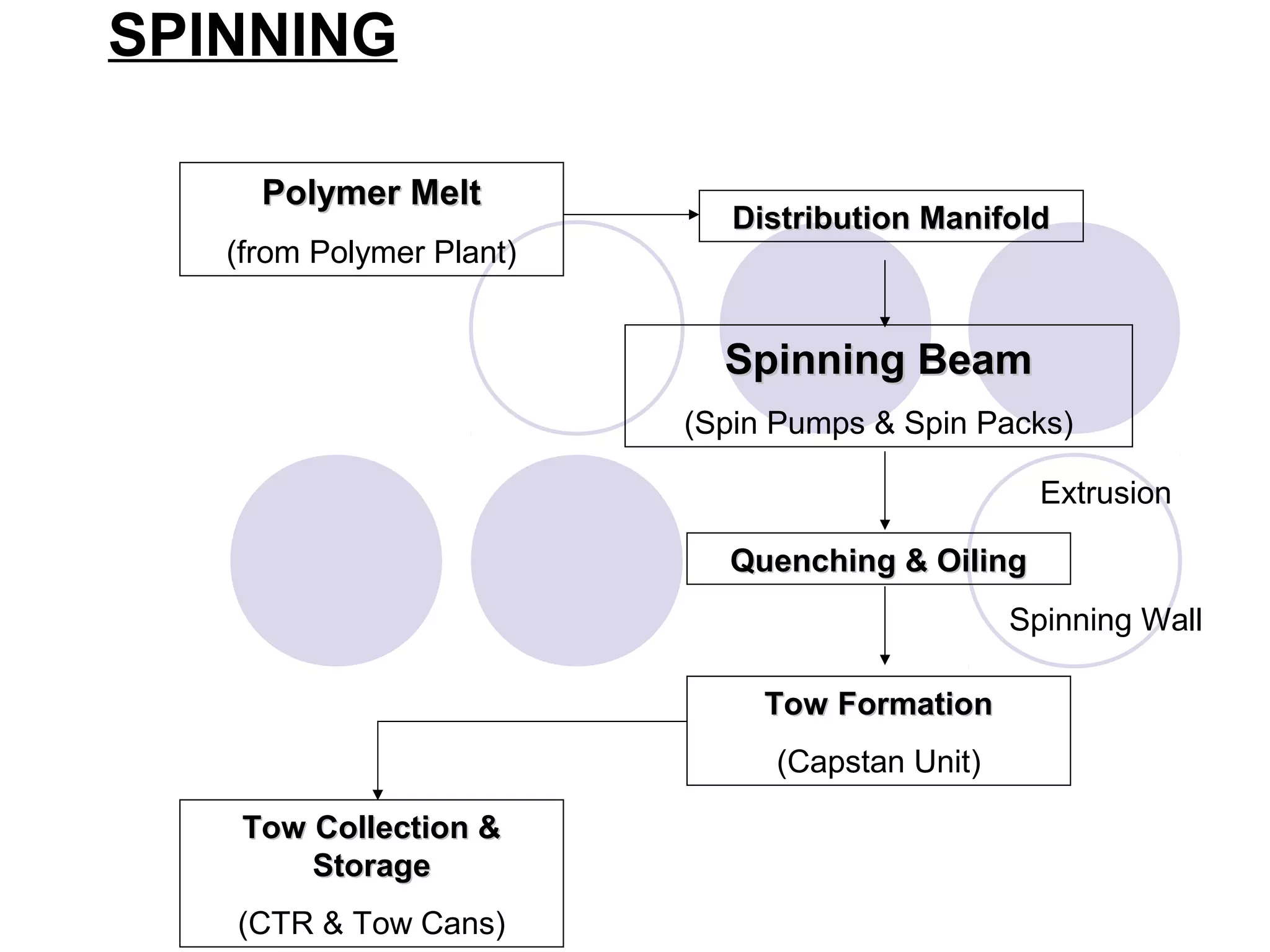

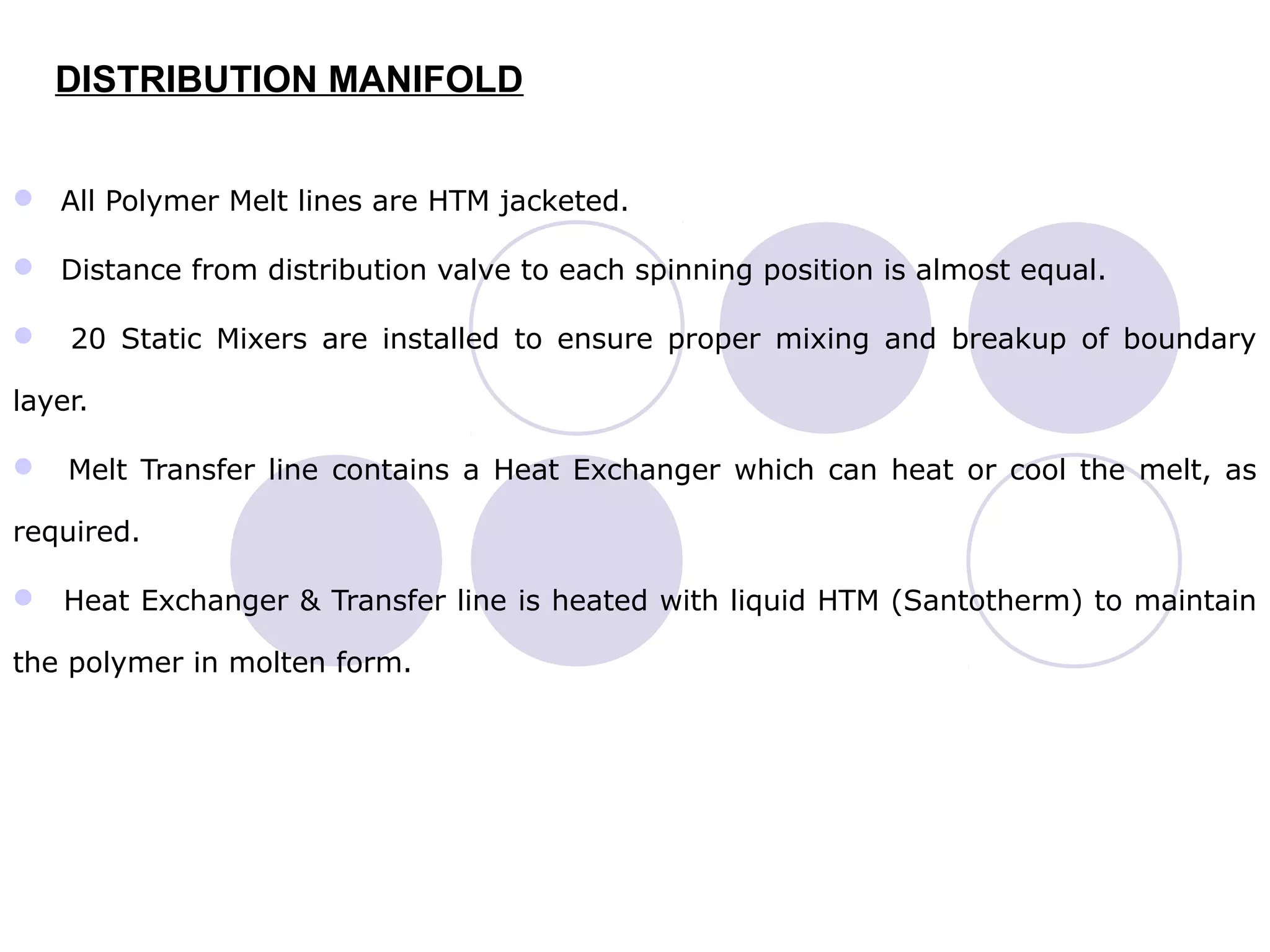

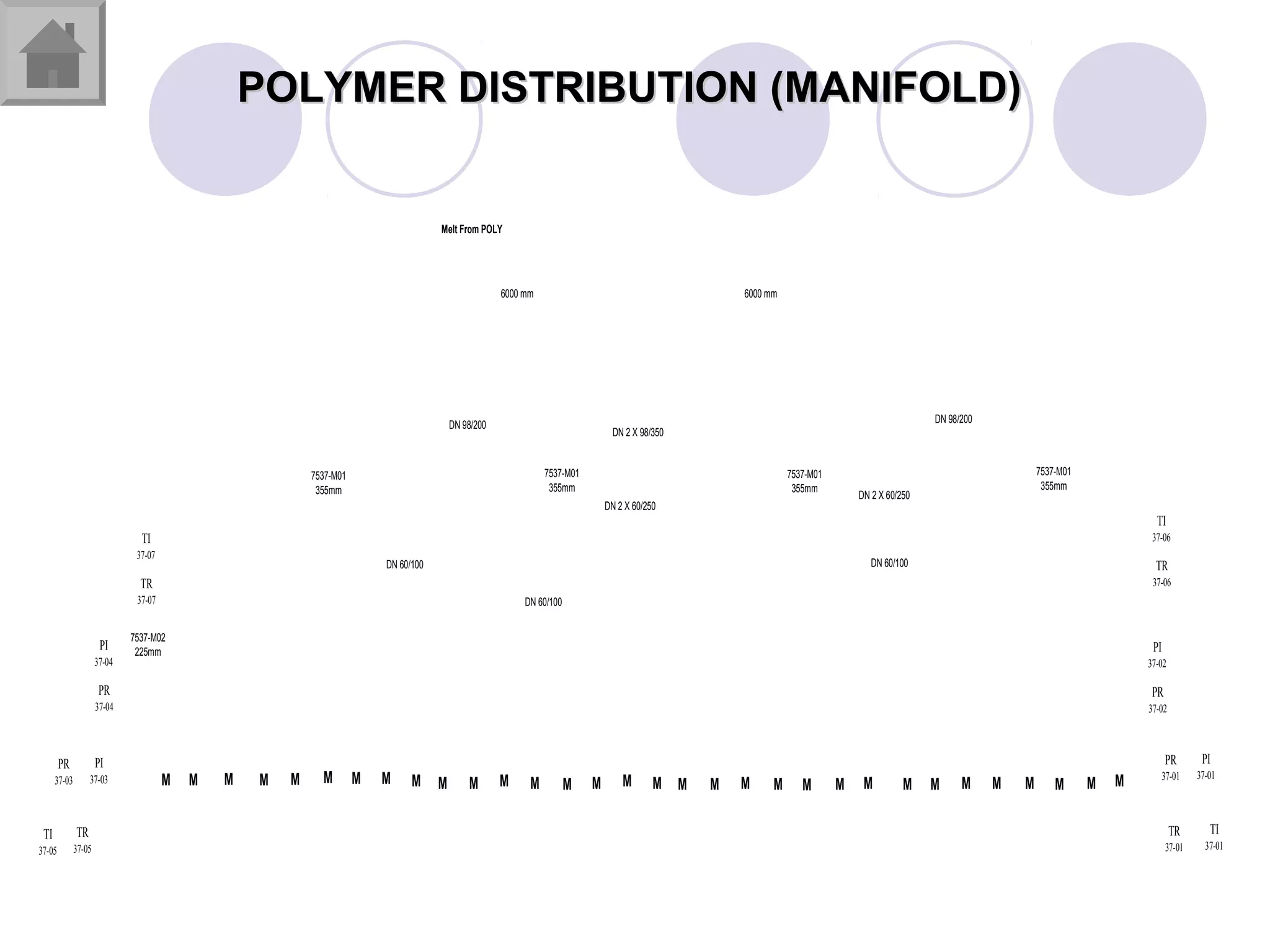

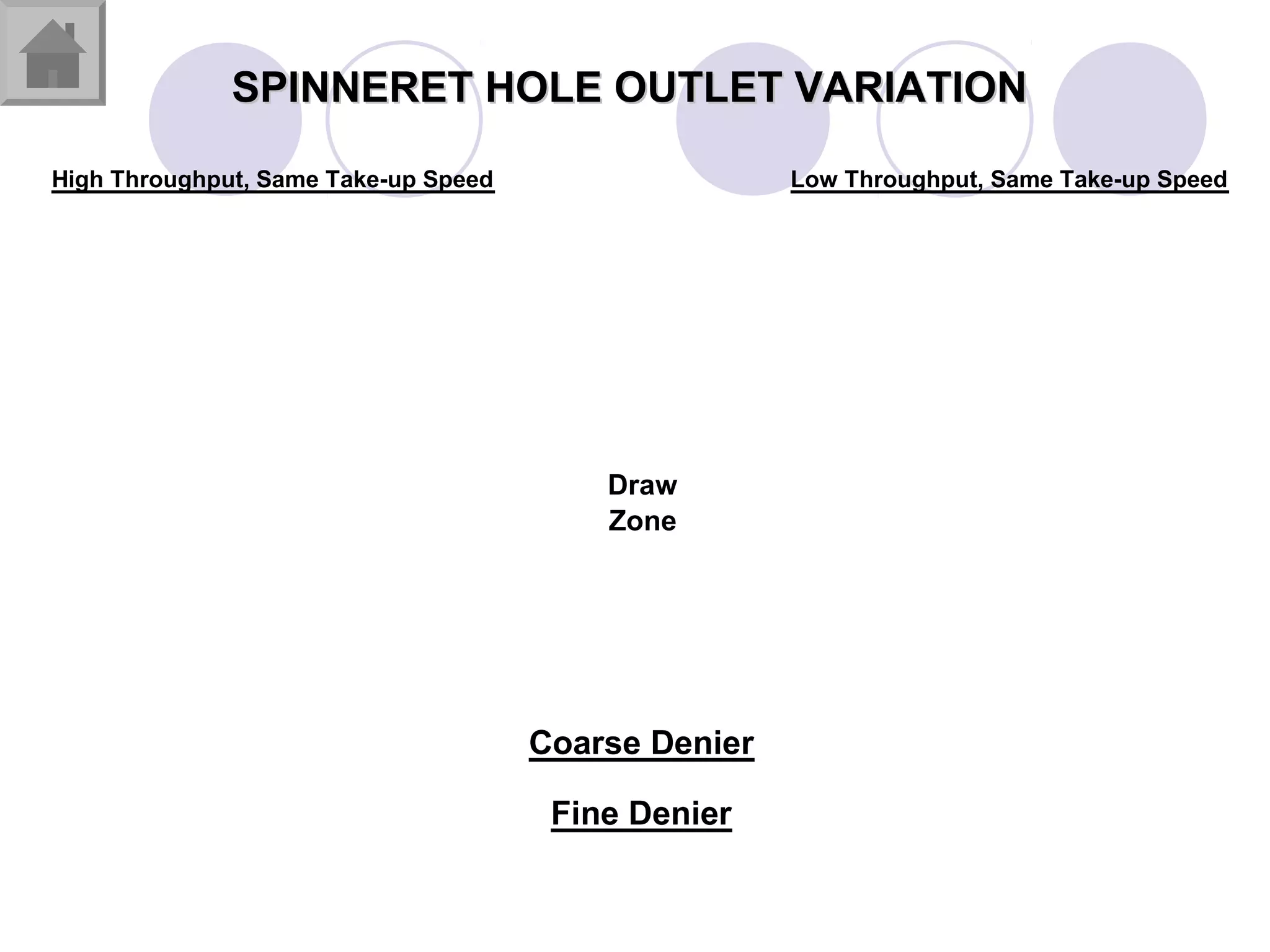

The document summarizes the key components and processes involved in the production of polyester fibers at Ibrahim Fibres Limited (IFL). IFL has two polyester plants (IFL-I and IFL-II) with a total production capacity of 586 tons per day. The plants use raw materials like PTA and MEG to produce polyester via esterification, polymerization, and polycondensation reactions. The molten polymer is then spun into fibers through an extrusion and spinning process that includes quenching, oiling, tow formation, and collection.