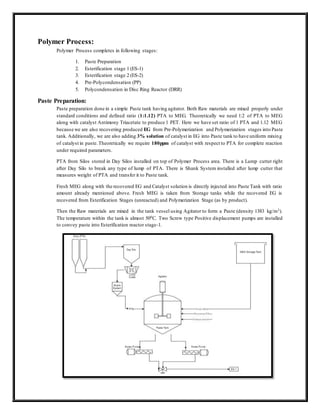

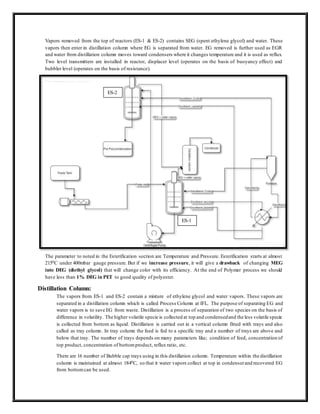

There are two additives - titanium dioxide (TDO) and antimony triacetate catalyst - used in the polyester process. TDO is added at the Esterification Stage 2 (ES-2) to make PET dull or white in color. The catalyst promotes the polycondensation reaction. The polymer process involves paste preparation, two stages of esterification (ES-1 and ES-2), pre-polycondensation, and polycondensation in a disc ring reactor. Heat is provided through a primary and secondary heat transfer medium system to maintain the required high temperatures.