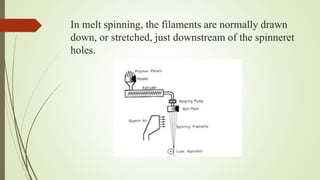

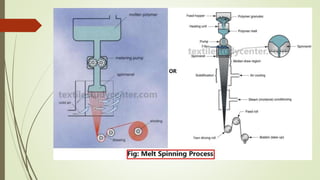

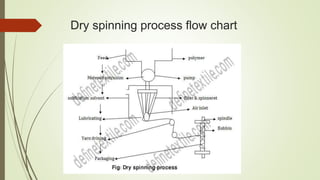

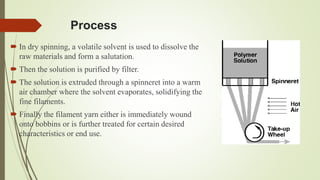

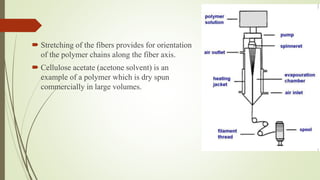

The document discusses different types of spinning processes used to create polymer fibers. It describes melt spinning, dry spinning, and wet spinning. In melt spinning, polymers are melted and extruded through a spinneret, then cooled. Dry spinning uses a volatile solvent and evaporates it using hot air. Wet spinning uses a non-volatile solvent and extrudes the solution into a coagulation bath to solidify the fibers. The document provides details of the processes, examples of polymers used for each type, and their advantages and disadvantages.