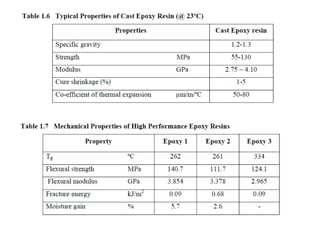

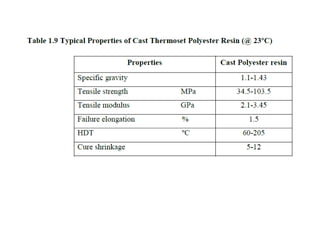

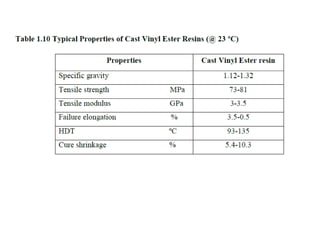

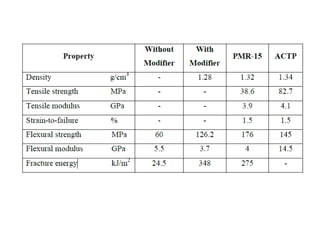

This document discusses different types of thermoset polymer matrices used in composite materials. It describes epoxy, polyester, vinyl ester, and polyimide resins. Epoxy resin is commonly used in aerospace structures due to its good adherence to fibers, curing options, and chemical resistance. However, it has relatively high cost and long curing time. Polyester resin is lower cost but has higher shrinkage and lower strength than epoxy. Vinyl ester resin combines properties of epoxy and polyester resins. Thermoset polyimides offer high temperature resistance but are inherently brittle. The document provides advantages and disadvantages as well as applications for each resin type.