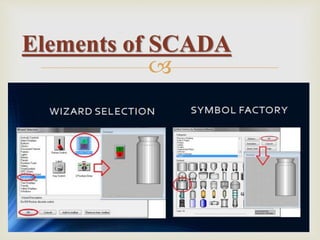

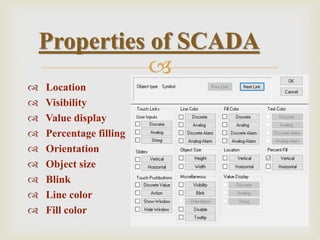

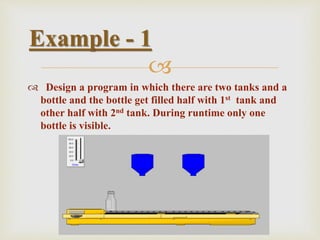

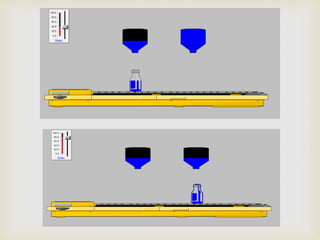

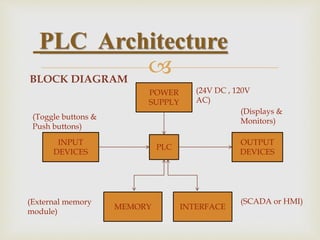

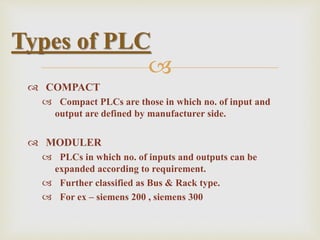

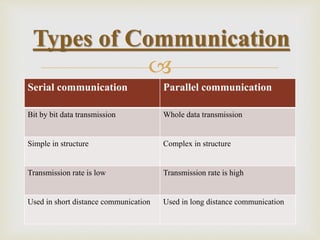

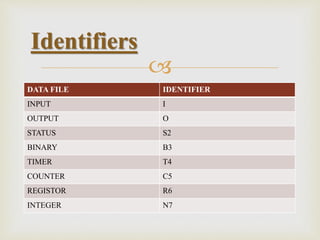

This document provides an overview of automation, PLCs, and SCADA systems. It discusses what automation and PLCs are, the history and elements of PLCs, their advantages and disadvantages, and applications. It also defines SCADA, discusses its history and elements, advantages like reduced costs and increased efficiency, disadvantages like security risks, and applications in areas like transportation and manufacturing.

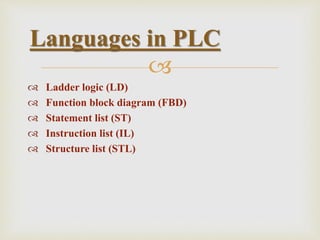

![

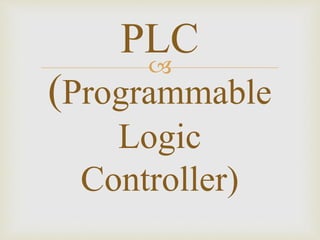

FOR INPUT

--[ ]-- {EXAMIN IF CLOSED}

--[/]-- {EXAMINE IF OPEN }

FOR OUTPUT

--( )-- Output{OTE}

--(L)-- Output latch{OTL}

--(U)-- Output unlatch{OTU}

Symbols used in PLC](https://image.slidesharecdn.com/plcandscada-200504100443/85/PLC-AND-SCADA-18-320.jpg)