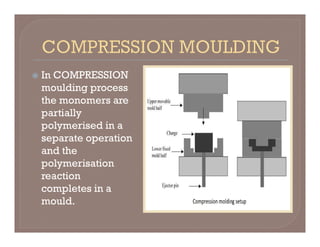

This document discusses various plastic molding methods including compression molding, transfer molding, injection molding, extrusion molding, and blow molding. Compression and transfer molding are used for thermosetting materials, while injection molding and extrusion molding are generally used for thermoplastics. The document provides details on the processes and typical temperatures, pressures, and cycle times for each method. Calendering and laminating are also briefly described.