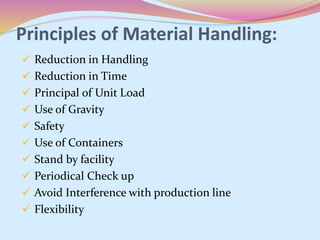

This document discusses material handling in industrial engineering. Material handling involves transporting raw materials and parts within a facility using manual or mechanical methods. It describes the functions of material handling as moving materials for storage, transportation between departments, and loading/unloading trucks. The objectives are to implement efficient, safe and economical material handling methods. Key factors considered are engineering aspects like material properties and layout, as well as economic factors like costs. Principles of effective material handling include reducing handling time and amounts, using unit loads, gravity where possible, and safety. Common material handling devices are lifting/lowering devices, transport devices, and devices that combine both functions.