The document summarizes a factory visit by students to Northern Fashion Limited, a knit composite factory. The key sections covered in the factory include:

1. The knitting section which uses weft and warp knitting machines to produce single jersey, double jersey, interlock, and warp knit fabrics.

2. The dyeing section which uses reactive dyeing processes and has dyeing machines with capacities up to 60 tons per day.

3. The finishing section which includes calendaring and compacting to improve fabric texture.

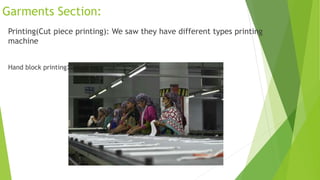

4. The garments section covers cutting, different printing methods like hand block and automatic printing, and the line layout for sewing.