Garments in bangladesh

•Download as PPTX, PDF•

1 like•550 views

History of Garments

Report

Share

Report

Share

Recommended

Study on V.D.Q Pulley

VDQ pulley (Variable Dia for Quality Pulley): It is a very important part of the machine. It controls the quality of the product. Altering the position of the tension pulley changes the G.S.M. of the fabric.

Presentation on stenter machine

A machine or apparatus for stretching or stentering fabrics. The purpose of the Stenter machine is to bringing the length and width to pre determine dimensions and also for heat setting and it is used for applying finishing chemicals and also shade variation is adjusted. The main function of the Stenter is to stretch the fabric widthwise and to recover the uniform width.

Recommended

Study on V.D.Q Pulley

VDQ pulley (Variable Dia for Quality Pulley): It is a very important part of the machine. It controls the quality of the product. Altering the position of the tension pulley changes the G.S.M. of the fabric.

Presentation on stenter machine

A machine or apparatus for stretching or stentering fabrics. The purpose of the Stenter machine is to bringing the length and width to pre determine dimensions and also for heat setting and it is used for applying finishing chemicals and also shade variation is adjusted. The main function of the Stenter is to stretch the fabric widthwise and to recover the uniform width.

Parameters of finishing machine

The term finishing, in a broad sense it covers all the processes of making the fabric good looking, good hand feeling, luster and of course for buyer requirement. It is done after dying and before delivery to market. Various types of parameters are controlled during finishing section considering buyer requirement. The term also includes bleaching, dyeing, mercerizing etc. But normally the term is restricted to the final stage in the sequence of treatment of Knit fabrics after bleaching and dyeing. However, fabrics which are neither bleached nor dyed are also finished.

Tricot Warp Knitting Machine

This presentation slide represents a tricot machine and its knitting action.

Presentation on Weft Knitting Machine (Single Jersey, Rib & Interlock)

Weft Knitting Machine (Single Jersey, Rib & Interlock)

Jet weaving

Weft insertion by air jet or water jet is a modern concept of weft insertion to produce woven fabric.

Study on knitting elements of circular knitting machine (butex)

Study on knitting elements of circular knitting machine (butex)Bangladesh University of Textiles (BUTEX)

study knitting elementKeighley Dobby (negative- double lift)

You can find the diffences between mechanical and electronical dobby mechanisms in principle in this presentation.

Also , you can reach the details of dobby mechanisms type like as of single , double and negative dobby systems.

Knitting Technology | Study On Knitting Technology | Sweater/ V-bed Flat Knit...

> Knitting Technology

> Sweater/ V-bed Flat Knitting Machine

Production Process of fully fashioned knitwear manufacturing.

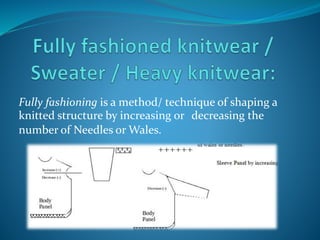

Fully fashioning is a method of shaping knitted structure by increasing or decreasing the number of Wales or needles. Fully fashioned knitwear is manufactured through knitting the whole structure.

More Related Content

What's hot

Parameters of finishing machine

The term finishing, in a broad sense it covers all the processes of making the fabric good looking, good hand feeling, luster and of course for buyer requirement. It is done after dying and before delivery to market. Various types of parameters are controlled during finishing section considering buyer requirement. The term also includes bleaching, dyeing, mercerizing etc. But normally the term is restricted to the final stage in the sequence of treatment of Knit fabrics after bleaching and dyeing. However, fabrics which are neither bleached nor dyed are also finished.

Tricot Warp Knitting Machine

This presentation slide represents a tricot machine and its knitting action.

Presentation on Weft Knitting Machine (Single Jersey, Rib & Interlock)

Weft Knitting Machine (Single Jersey, Rib & Interlock)

Jet weaving

Weft insertion by air jet or water jet is a modern concept of weft insertion to produce woven fabric.

Study on knitting elements of circular knitting machine (butex)

Study on knitting elements of circular knitting machine (butex)Bangladesh University of Textiles (BUTEX)

study knitting elementKeighley Dobby (negative- double lift)

You can find the diffences between mechanical and electronical dobby mechanisms in principle in this presentation.

Also , you can reach the details of dobby mechanisms type like as of single , double and negative dobby systems.

Knitting Technology | Study On Knitting Technology | Sweater/ V-bed Flat Knit...

> Knitting Technology

> Sweater/ V-bed Flat Knitting Machine

What's hot (20)

Presentation on Weft Knitting Machine (Single Jersey, Rib & Interlock)

Presentation on Weft Knitting Machine (Single Jersey, Rib & Interlock)

Study on knitting elements of circular knitting machine (butex)

Study on knitting elements of circular knitting machine (butex)

Knitting Technology | Study On Knitting Technology | Sweater/ V-bed Flat Knit...

Knitting Technology | Study On Knitting Technology | Sweater/ V-bed Flat Knit...

A compressive study on rib circular knitting machine

A compressive study on rib circular knitting machine

Similar to Garments in bangladesh

Production Process of fully fashioned knitwear manufacturing.

Fully fashioning is a method of shaping knitted structure by increasing or decreasing the number of Wales or needles. Fully fashioned knitwear is manufactured through knitting the whole structure.

(Sir Ashraful Alam) Full PDF Apparel Manufacturing I Sheet Part-2

(Ashraful Alam) Full PDF Apparel Manufacturing I Sheet Part-2 | Full PDF Apparel Manufacturing Sheet Part-2

Apparel i (term final)

This file contains Apparel Spreading & Cutting section as well as the use of computer in apparel manufacturing.

Weft knitting machine & parameters of weft knitted fabric

Knitting is the interloping of yarn which is interlocking in various ways to form fabric. Knitting is the process of manufacturing fabric by transforming continuous strands of yarn into a series of interlocking loops, each row of such loops hanging from the one immediately preceding it. The basic element of knit fabric structure is the loop intermeshed with the loop adjacent to it on both sides and above and below it.

Knitting technology

Dear Viewers ,

Good News to you.

Here I Attach a Assignment To you. Its helped to u make a Assignment in Knit Technology.

Tnx to all.

Presentation on cutting section

I hope this presentation will help you to know about the cutting department of garments section. Though, there will be some up and downs for process optimization otherwise all good. I hope this will help you guys.

Fabric inspections

Fabric Inspections - The usual process at a fabric inspection of a Sri Lankan Apparel Manufacturer.

Quality control management

Presentation Topic: "Fabric Defects. Its Causes & Remedies."

Presented By: Asif-Al-Jaman

Institute: Chattogram BGMEA Institute of Fashion & Technology (CBIFT)

Dept.: Apparel Manufacture & Technology (AMT)

Similar to Garments in bangladesh (20)

Production Process of fully fashioned knitwear manufacturing.

Production Process of fully fashioned knitwear manufacturing.

Production Process of garments industry (knitwear)

Production Process of garments industry (knitwear)

(Sir Ashraful Alam) Full PDF Apparel Manufacturing I Sheet Part-2

(Sir Ashraful Alam) Full PDF Apparel Manufacturing I Sheet Part-2

Weft knitting machine & parameters of weft knitted fabric

Weft knitting machine & parameters of weft knitted fabric

Magnum Clothing Private Limited, Industrial Report

Magnum Clothing Private Limited, Industrial Report

Recently uploaded

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

Advancements in technology unveil a myriad of electrical and electronic breakthroughs geared towards efficiently harnessing limited resources to meet human energy demands. The optimization of hybrid solar PV panels and pumped hydro energy supply systems plays a pivotal role in utilizing natural resources effectively. This initiative not only benefits humanity but also fosters environmental sustainability. The study investigated the design optimization of these hybrid systems, focusing on understanding solar radiation patterns, identifying geographical influences on solar radiation, formulating a mathematical model for system optimization, and determining the optimal configuration of PV panels and pumped hydro storage. Through a comparative analysis approach and eight weeks of data collection, the study addressed key research questions related to solar radiation patterns and optimal system design. The findings highlighted regions with heightened solar radiation levels, showcasing substantial potential for power generation and emphasizing the system's efficiency. Optimizing system design significantly boosted power generation, promoted renewable energy utilization, and enhanced energy storage capacity. The study underscored the benefits of optimizing hybrid solar PV panels and pumped hydro energy supply systems for sustainable energy usage. Optimizing the design of solar PV panels and pumped hydro energy supply systems as examined across diverse climatic conditions in a developing country, not only enhances power generation but also improves the integration of renewable energy sources and boosts energy storage capacities, particularly beneficial for less economically prosperous regions. Additionally, the study provides valuable insights for advancing energy research in economically viable areas. Recommendations included conducting site-specific assessments, utilizing advanced modeling tools, implementing regular maintenance protocols, and enhancing communication among system components.

Automobile Management System Project Report.pdf

The proposed project is developed to manage the automobile in the automobile dealer company. The main module in this project is login, automobile management, customer management, sales, complaints and reports. The first module is the login. The automobile showroom owner should login to the project for usage. The username and password are verified and if it is correct, next form opens. If the username and password are not correct, it shows the error message.

When a customer search for a automobile, if the automobile is available, they will be taken to a page that shows the details of the automobile including automobile name, automobile ID, quantity, price etc. “Automobile Management System” is useful for maintaining automobiles, customers effectively and hence helps for establishing good relation between customer and automobile organization. It contains various customized modules for effectively maintaining automobiles and stock information accurately and safely.

When the automobile is sold to the customer, stock will be reduced automatically. When a new purchase is made, stock will be increased automatically. While selecting automobiles for sale, the proposed software will automatically check for total number of available stock of that particular item, if the total stock of that particular item is less than 5, software will notify the user to purchase the particular item.

Also when the user tries to sale items which are not in stock, the system will prompt the user that the stock is not enough. Customers of this system can search for a automobile; can purchase a automobile easily by selecting fast. On the other hand the stock of automobiles can be maintained perfectly by the automobile shop manager overcoming the drawbacks of existing system.

Event Management System Vb Net Project Report.pdf

In present era, the scopes of information technology growing with a very fast .We do not see any are untouched from this industry. The scope of information technology has become wider includes: Business and industry. Household Business, Communication, Education, Entertainment, Science, Medicine, Engineering, Distance Learning, Weather Forecasting. Carrier Searching and so on.

My project named “Event Management System” is software that store and maintained all events coordinated in college. It also helpful to print related reports. My project will help to record the events coordinated by faculties with their Name, Event subject, date & details in an efficient & effective ways.

In my system we have to make a system by which a user can record all events coordinated by a particular faculty. In our proposed system some more featured are added which differs it from the existing system such as security.

一比一原版(SFU毕业证)西蒙菲莎大学毕业证成绩单如何办理

SFU毕业证原版定制【微信:176555708】【西蒙菲莎大学毕业证成绩单-学位证】【微信:176555708】(留信学历认证永久存档查询)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

◆◆◆◆◆ — — — — — — — — 【留学教育】留学归国服务中心 — — — — — -◆◆◆◆◆

【主营项目】

一.毕业证【微信:176555708】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【微信:176555708】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分→ 【关于价格问题(保证一手价格)

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

选择实体注册公司办理,更放心,更安全!我们的承诺:可来公司面谈,可签订合同,会陪同客户一起到教育部认证窗口递交认证材料,客户在教育部官方认证查询网站查询到认证通过结果后付款,不成功不收费!

学历顾问:微信:176555708

Nuclear Power Economics and Structuring 2024

Title: Nuclear Power Economics and Structuring - 2024 Edition

Produced by: World Nuclear Association Published: April 2024

Report No. 2024/001

© 2024 World Nuclear Association.

Registered in England and Wales, company number 01215741

This report reflects the views

of industry experts but does not

necessarily represent those

of World Nuclear Association’s

individual member organizations.

COLLEGE BUS MANAGEMENT SYSTEM PROJECT REPORT.pdf

The College Bus Management system is completely developed by Visual Basic .NET Version. The application is connect with most secured database language MS SQL Server. The application is develop by using best combination of front-end and back-end languages. The application is totally design like flat user interface. This flat user interface is more attractive user interface in 2017. The application is gives more important to the system functionality. The application is to manage the student’s details, driver’s details, bus details, bus route details, bus fees details and more. The application has only one unit for admin. The admin can manage the entire application. The admin can login into the application by using username and password of the admin. The application is develop for big and small colleges. It is more user friendly for non-computer person. Even they can easily learn how to manage the application within hours. The application is more secure by the admin. The system will give an effective output for the VB.Net and SQL Server given as input to the system. The compiled java program given as input to the system, after scanning the program will generate different reports. The application generates the report for users. The admin can view and download the report of the data. The application deliver the excel format reports. Because, excel formatted reports is very easy to understand the income and expense of the college bus. This application is mainly develop for windows operating system users. In 2017, 73% of people enterprises are using windows operating system. So the application will easily install for all the windows operating system users. The application-developed size is very low. The application consumes very low space in disk. Therefore, the user can allocate very minimum local disk space for this application.

TECHNICAL TRAINING MANUAL GENERAL FAMILIARIZATION COURSE

AIRCRAFT GENERAL

The Single Aisle is the most advanced family aircraft in service today, with fly-by-wire flight controls.

The A318, A319, A320 and A321 are twin-engine subsonic medium range aircraft.

The family offers a choice of engines

The Benefits and Techniques of Trenchless Pipe Repair.pdf

Explore the innovative world of trenchless pipe repair with our comprehensive guide, "The Benefits and Techniques of Trenchless Pipe Repair." This document delves into the modern methods of repairing underground pipes without the need for extensive excavation, highlighting the numerous advantages and the latest techniques used in the industry.

Learn about the cost savings, reduced environmental impact, and minimal disruption associated with trenchless technology. Discover detailed explanations of popular techniques such as pipe bursting, cured-in-place pipe (CIPP) lining, and directional drilling. Understand how these methods can be applied to various types of infrastructure, from residential plumbing to large-scale municipal systems.

Ideal for homeowners, contractors, engineers, and anyone interested in modern plumbing solutions, this guide provides valuable insights into why trenchless pipe repair is becoming the preferred choice for pipe rehabilitation. Stay informed about the latest advancements and best practices in the field.

WATER CRISIS and its solutions-pptx 1234

Water scarcity is the lack of fresh water resources to meet the standard water demand. There are two type of water scarcity. One is physical. The other is economic water scarcity.

Architectural Portfolio Sean Lockwood

This portfolio contains selected projects I completed during my undergraduate studies. 2018 - 2023

CFD Simulation of By-pass Flow in a HRSG module by R&R Consult.pptx

CFD analysis is incredibly effective at solving mysteries and improving the performance of complex systems!

Here's a great example: At a large natural gas-fired power plant, where they use waste heat to generate steam and energy, they were puzzled that their boiler wasn't producing as much steam as expected.

R&R and Tetra Engineering Group Inc. were asked to solve the issue with reduced steam production.

An inspection had shown that a significant amount of hot flue gas was bypassing the boiler tubes, where the heat was supposed to be transferred.

R&R Consult conducted a CFD analysis, which revealed that 6.3% of the flue gas was bypassing the boiler tubes without transferring heat. The analysis also showed that the flue gas was instead being directed along the sides of the boiler and between the modules that were supposed to capture the heat. This was the cause of the reduced performance.

Based on our results, Tetra Engineering installed covering plates to reduce the bypass flow. This improved the boiler's performance and increased electricity production.

It is always satisfying when we can help solve complex challenges like this. Do your systems also need a check-up or optimization? Give us a call!

Work done in cooperation with James Malloy and David Moelling from Tetra Engineering.

More examples of our work https://www.r-r-consult.dk/en/cases-en/

Standard Reomte Control Interface - Neometrix

About

Indigenized remote control interface card suitable for MAFI system CCR equipment. Compatible for IDM8000 CCR. Backplane mounted serial and TCP/Ethernet communication module for CCR remote access. IDM 8000 CCR remote control on serial and TCP protocol.

• Remote control: Parallel or serial interface.

• Compatible with MAFI CCR system.

• Compatible with IDM8000 CCR.

• Compatible with Backplane mount serial communication.

• Compatible with commercial and Defence aviation CCR system.

• Remote control system for accessing CCR and allied system over serial or TCP.

• Indigenized local Support/presence in India.

• Easy in configuration using DIP switches.

Technical Specifications

Indigenized remote control interface card suitable for MAFI system CCR equipment. Compatible for IDM8000 CCR. Backplane mounted serial and TCP/Ethernet communication module for CCR remote access. IDM 8000 CCR remote control on serial and TCP protocol.

Key Features

Indigenized remote control interface card suitable for MAFI system CCR equipment. Compatible for IDM8000 CCR. Backplane mounted serial and TCP/Ethernet communication module for CCR remote access. IDM 8000 CCR remote control on serial and TCP protocol.

• Remote control: Parallel or serial interface

• Compatible with MAFI CCR system

• Copatiable with IDM8000 CCR

• Compatible with Backplane mount serial communication.

• Compatible with commercial and Defence aviation CCR system.

• Remote control system for accessing CCR and allied system over serial or TCP.

• Indigenized local Support/presence in India.

Application

• Remote control: Parallel or serial interface.

• Compatible with MAFI CCR system.

• Compatible with IDM8000 CCR.

• Compatible with Backplane mount serial communication.

• Compatible with commercial and Defence aviation CCR system.

• Remote control system for accessing CCR and allied system over serial or TCP.

• Indigenized local Support/presence in India.

• Easy in configuration using DIP switches.

Immunizing Image Classifiers Against Localized Adversary Attacks

This paper addresses the vulnerability of deep learning models, particularly convolutional neural networks

(CNN)s, to adversarial attacks and presents a proactive training technique designed to counter them. We

introduce a novel volumization algorithm, which transforms 2D images into 3D volumetric representations.

When combined with 3D convolution and deep curriculum learning optimization (CLO), itsignificantly improves

the immunity of models against localized universal attacks by up to 40%. We evaluate our proposed approach

using contemporary CNN architectures and the modified Canadian Institute for Advanced Research (CIFAR-10

and CIFAR-100) and ImageNet Large Scale Visual Recognition Challenge (ILSVRC12) datasets, showcasing

accuracy improvements over previous techniques. The results indicate that the combination of the volumetric

input and curriculum learning holds significant promise for mitigating adversarial attacks without necessitating

adversary training.

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Recently uploaded (20)

block diagram and signal flow graph representation

block diagram and signal flow graph representation

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

TECHNICAL TRAINING MANUAL GENERAL FAMILIARIZATION COURSE

TECHNICAL TRAINING MANUAL GENERAL FAMILIARIZATION COURSE

The Benefits and Techniques of Trenchless Pipe Repair.pdf

The Benefits and Techniques of Trenchless Pipe Repair.pdf

CFD Simulation of By-pass Flow in a HRSG module by R&R Consult.pptx

CFD Simulation of By-pass Flow in a HRSG module by R&R Consult.pptx

LIGA(E)11111111111111111111111111111111111111111.ppt

LIGA(E)11111111111111111111111111111111111111111.ppt

Immunizing Image Classifiers Against Localized Adversary Attacks

Immunizing Image Classifiers Against Localized Adversary Attacks

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Gen AI Study Jams _ For the GDSC Leads in India.pdf

Garments in bangladesh

- 1. Fully fashioning is a method/ technique of shaping a knitted structure by increasing or decreasing the number of Needles or Wales.

- 2. Most common sweater machine in Bangladesh: Knitting Machine: Hand driven flat knitting machine. 3 Gauges, 5 Gauges, 7 Gauges, 10 Gauges, 12 Gauges, 14 gauges. Jacquard All gauges can be made in jacquard machine. Linking Machine: Dial linking machine 5 Gauges, 6 Gauges, 7 Gauges, 8 Gauges, 14 Gauges, 16 Gauges

- 3. Most common Yarn Basic Type: Fancy Type: 100% Acrylic Acrylic Mélange Blended Acrylic 100% Wool Mixed Wool 100% Cotton Blended Cotton etc. Chenille Angora tweed Nap yarn/ Slub yarn Mohair Tape yarn Cashmere Loop yarn Popcorn etc.

- 4. Most common Stitch Basic Stitch: Jersey stitch Rib Stitch Double Stitch Fancy Stitch: Shaker or half cardigan stitch, full cardigan Drop knit tuck knit Milano stitch pointelle zigzag stitch cable stitch diamond

- 5. FULLY FASHIONED MAKING PROCESS FLOW CHART Warehouse arrangement & yarn inspection Winding section Yarn cone distribution section Knitting section Knitted panel inspection. Linking section Linking inspection section Trimming section/ Linking continue Light check inspection Mending section Washing & drying section Pressing / Ironing section Finishing section

- 6. Warehouse arrangement & yarn inspection As per buyer requirement we will purchase the yarn from yarn supplier. It can be local or foreign yarn. Before purchase the yarn we must need clear idea regarding the wastage percentage of the each types yarn. Wastage consider in case of types of gauge and material quality: In case of normal gauge/ regular gauge (3G, 5G, 7G); 4% production wastage is considered except chenille yarn. In case of fine gauge (10G, 12G) add 1% more wastage for any fine yarn except chenille yarn. So production wastage is 4%+1%=5%. In case of chenille yarn add 1% more wastage to the normal gauge and fine gauge. So for normal gauge of chenille yarn wastage is 4%+1%=5% and fine gauge of chenille yarn 5%+1%=6%. After in-house the yarn we should store yarn by their types & count. And check or inspect the yarn: Color with swatch card, Quantity with order sheet.

- 7. Winding Section Winding section the yarn should be formed Hanks to Cone / hard cone to soft cone. After receive the yarn from supplier we need to wind these yarn by coning machine for knitting production. Winding machine

- 8. Yarn cone distribution section After winding the yarn it goes to yarn distribution section for distribution the yarn to the knitting floor. Here we must ensure that, the correct yarn is being distributed for correct gauge knitting machine. The distributor must distribute the yarn by weight basis and also the knitted panel should be returned accordingly to the distributor.

- 9. Knitting section In knitting section we should knit the body, sleeve etc of the sweater by knitting machine. The operators of knitting machine are called as knitting man. If the sweater is with placket then we will make the placket by auto placket machine. The decision to make by computer or hand machine is depended on the complexity of the design. Sometimes, intarsia design will be done. Hand driven flat knitting machine Jacquard machine.

- 10. Knitted panel inspection After knitting the body parts, it will be inspected by the Q.C team in the inspection section.

- 11. Linking section After pass the Q.C check, the body parts will be goes to the Linking section. In this section we join the front part, back part, sleeve etc with the Linking machine. Loop to loop connection is done manually for high quality garment. Linking process Linking machine

- 12. Linking inspection section Trimming section/ Linking continue After linking the body parts, it will be inspected by the Q.C team in the inspection section. In this section the body will be trimmed.

- 13. Light check inspection After linking the body parts, it will be inspected by the tubular light check machine.. And also marked the mending hole.

- 14. Mending section From trimming section it will go to mending section for mending on which hole has been marked in trimming section.

- 15. Washing & drying section In this section we wash & dry the sweater. Then we send it to the Iron section.

- 16. Pressing / Ironing section Here iron the body to fit the measurement and shape.

- 17. Finishing section After ironing the body we inspect the iron quality. After iron check we attached the label with the body by sewing machine also button and zipper can be join with body if those require. After attached the label with sweater, quality team check all over quality. It’s called final quality. After the final check we sent the sweater to packing section for poly & carton.

- 18. Conclusion From above presentation we understand that every step of manufacturing sweater is so important. Because if we don’t give strong follow up on every stage then bottle neck can be risen. So we should keep potential follow up on all stage.

- 19. Question?????

- 20. THANK YOU…….!