The document provides an overview of training programs for operators at Fariha Knit Tex Ltd. It includes:

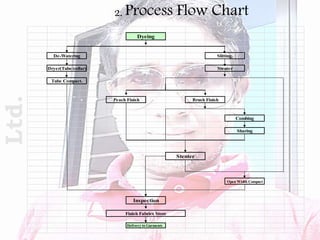

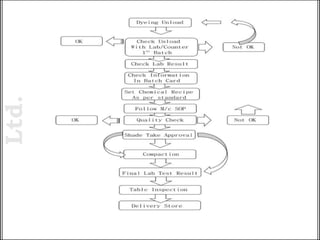

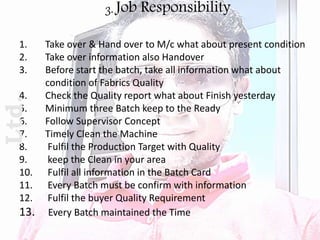

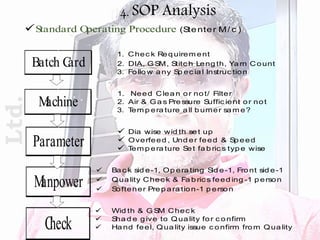

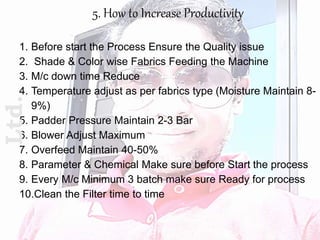

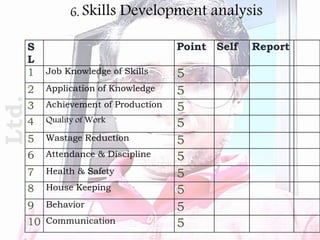

1. An outline of working procedures, process flow charts, job responsibilities, SOP analysis, and how to increase productivity.

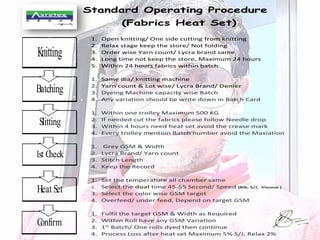

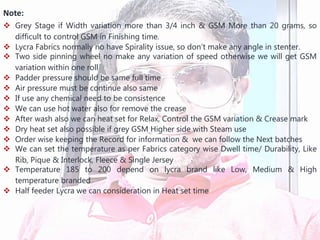

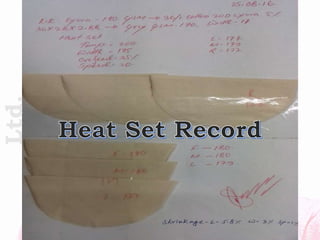

2. Details on standard operating procedures for heat setting fabrics, including batching, slitting, temperature settings, and ensuring quality standards.

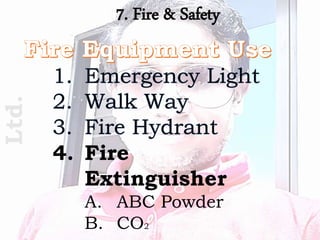

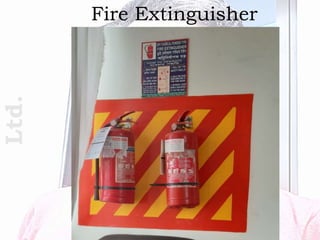

3. A discussion of fire safety practices like using appropriate extinguishers and exits, and wearing personal protective equipment during training.

The training aims to develop operator skills while maximizing output through strategies like minimizing downtime and maintaining proper chemical balances and temperatures tailored to different fabric types. Quality, safety, and compliance with production targets