This document provides an operator training program for H R Textile Mills ltd's Fabrics Finishing Department. The training covers:

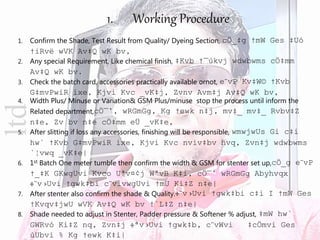

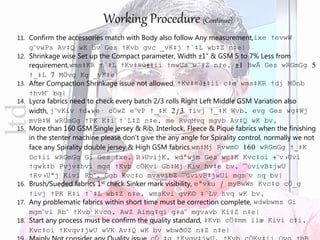

1) Working procedures such as quality checks, special requirements, and machine parameters

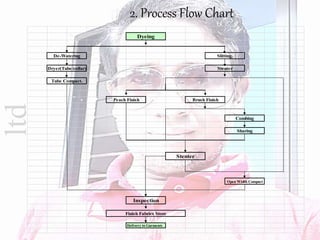

2) The process flow chart from delivery to finished fabrics storage

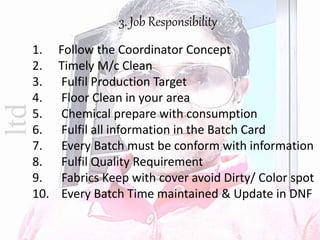

3) Job responsibilities including following procedures, meeting production targets, and quality requirements

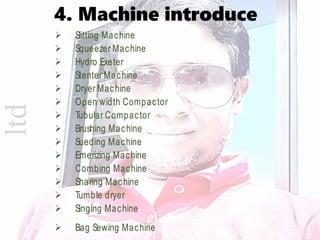

4) Introductions to machines used in fabrics finishing like slitters, stenters, and dryers

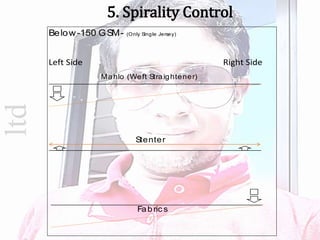

5) Spirality control procedures for single jersey fabrics

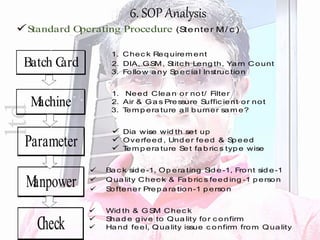

6) Standard operating procedures for machines like stenters

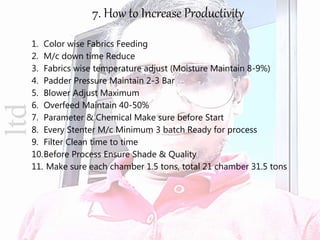

7) Methods for increasing productivity through optimized feeding and parameter adjustment

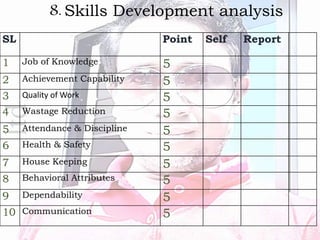

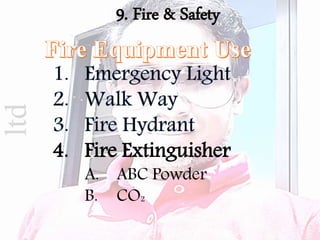

8) Skills development analysis and safety training on fire