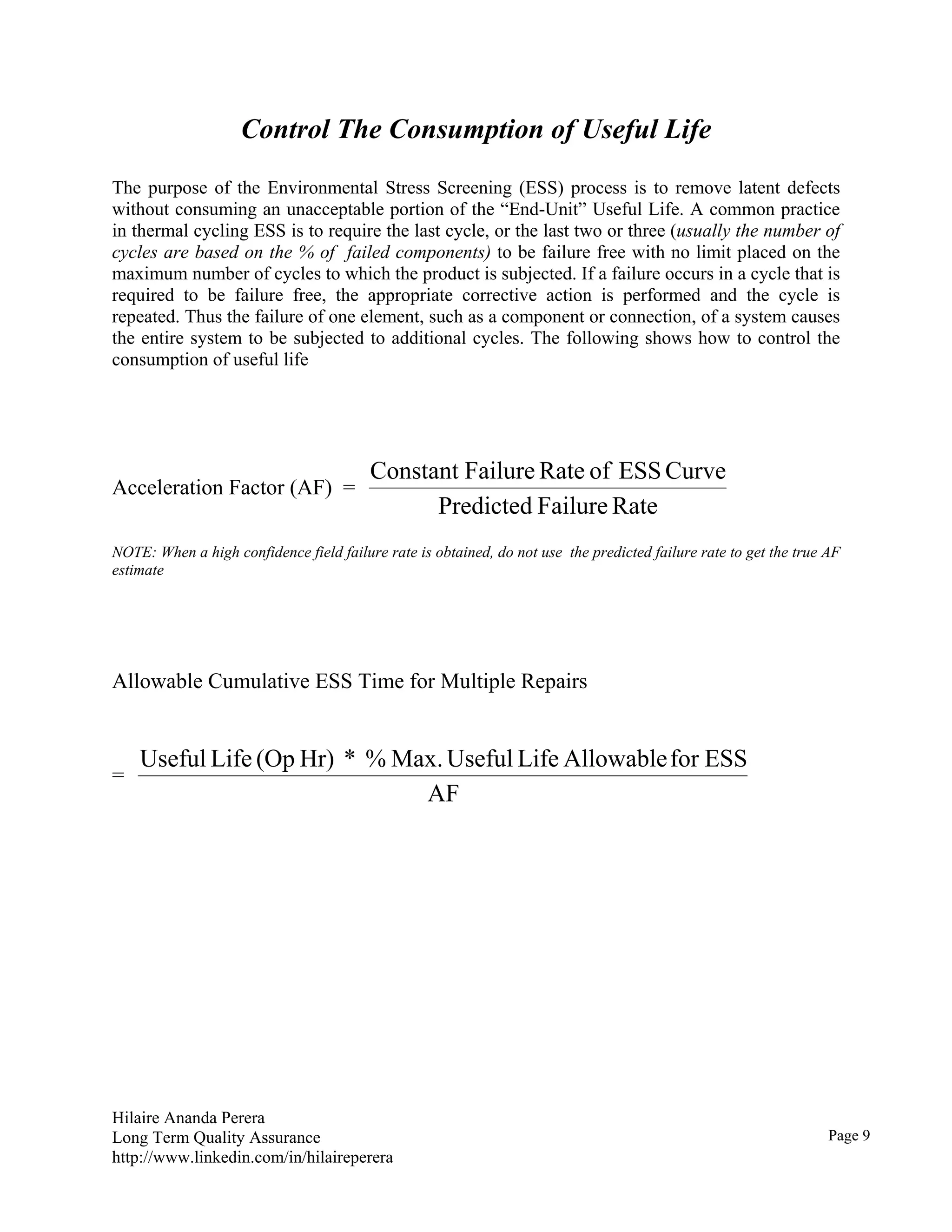

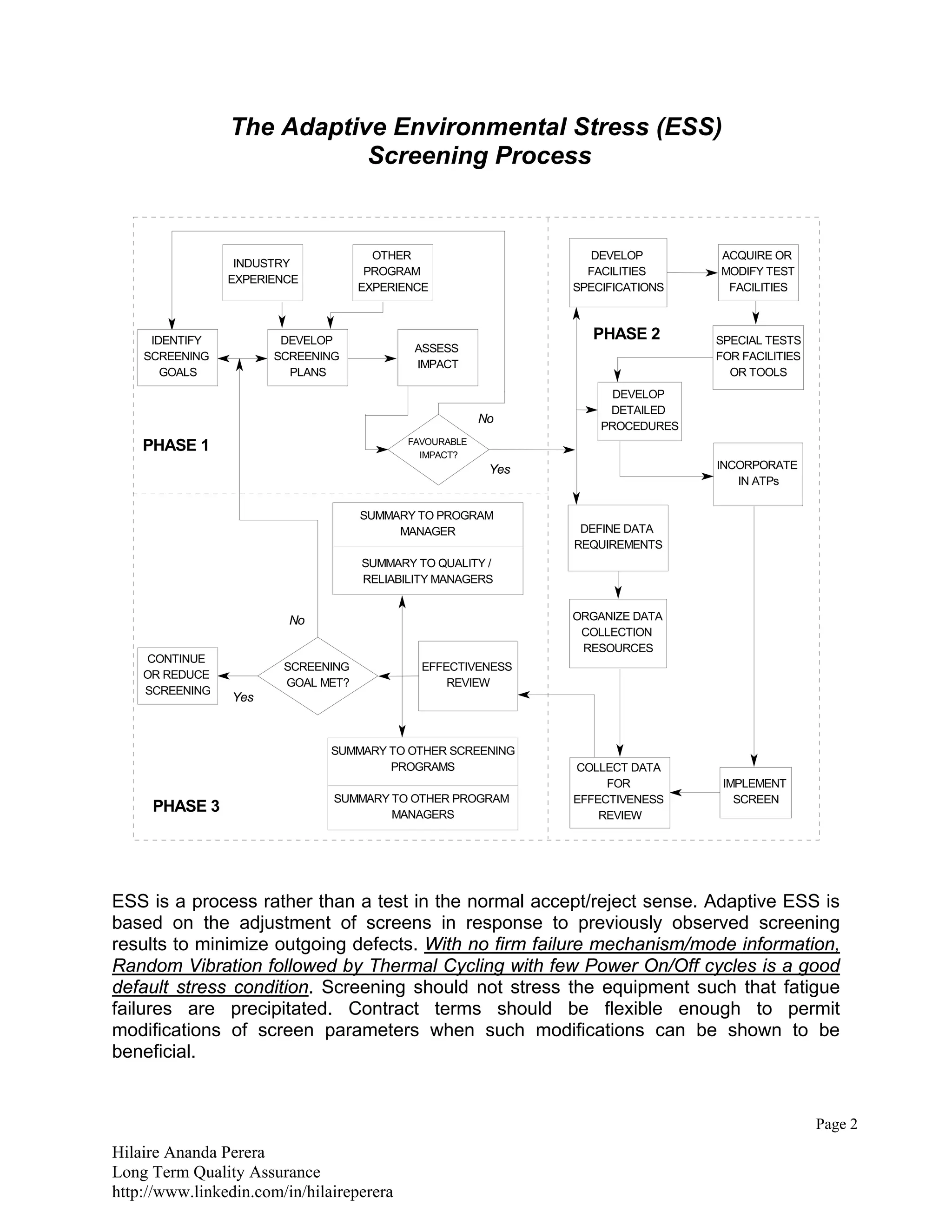

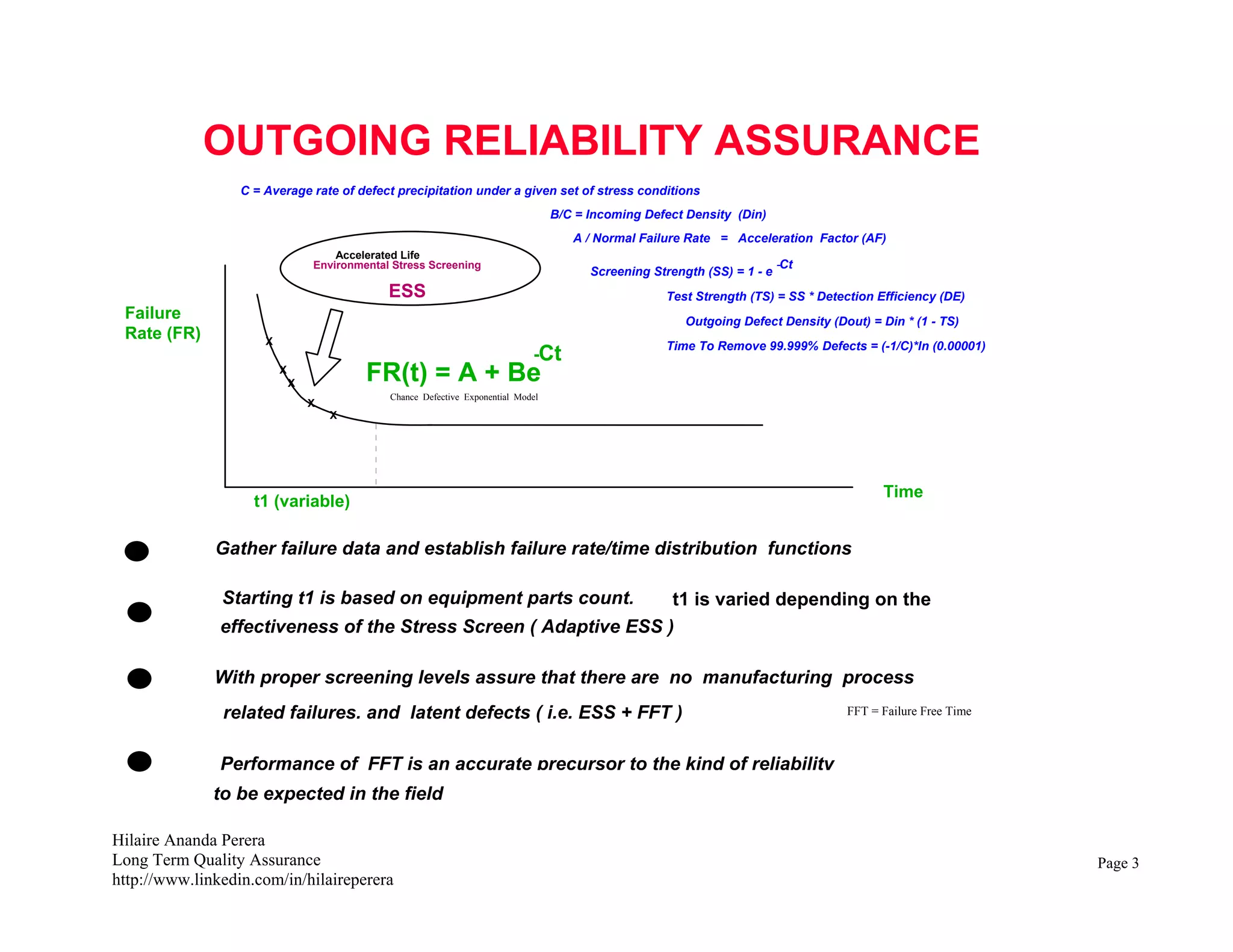

The document discusses environmental stress screening (ESS) processes used to test electronic products and remove latent defects. It notes that while ESS is commonly used, failure rate analysis is not always performed to evaluate screening effectiveness. The document recommends analyzing failure rate distributions over time using the Chance Defective Exponential model to determine optimal ESS screening times and ensure high outgoing quality. Adaptive ESS processes that adjust screening parameters based on results can further reduce defects.

![Hilaire Ananda Perera

Long Term Quality Assurance

http://www.linkedin.com/in/hilaireperera

EXAMPLE: Based on the Average Rate of Defect Precipitation of 0.3320 (For

details see Page 8) Defects/Hour, the Time To Remove 99.999% Defects is 34

Hours

NOTE 1: For multiple Screen Stops in a single unit, assume Total Cumulative Thermal

Energy during “No Fault Found (NFF)” and/or “Burn-in Equipment (BIE)” failure

and for true failure responsible for failure precipitation.

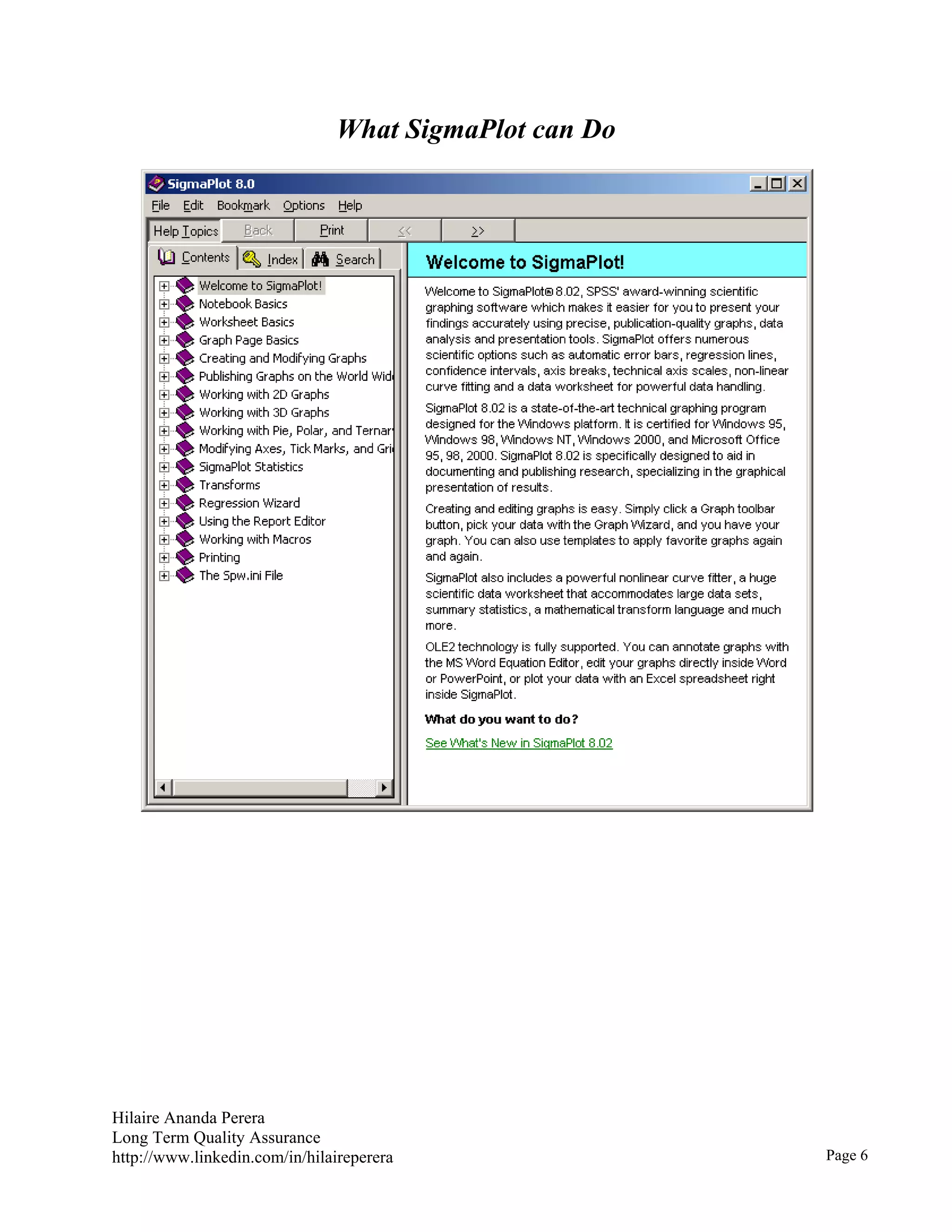

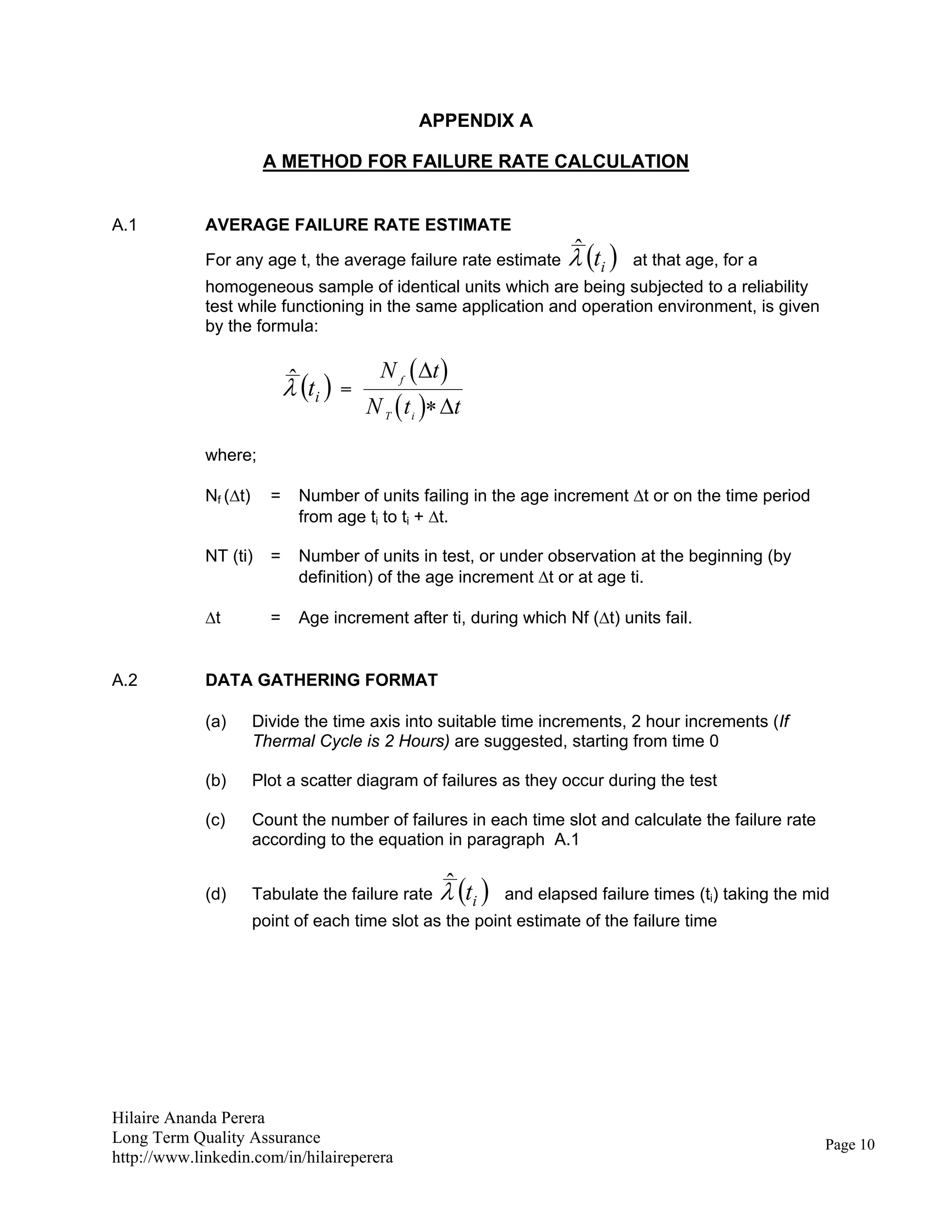

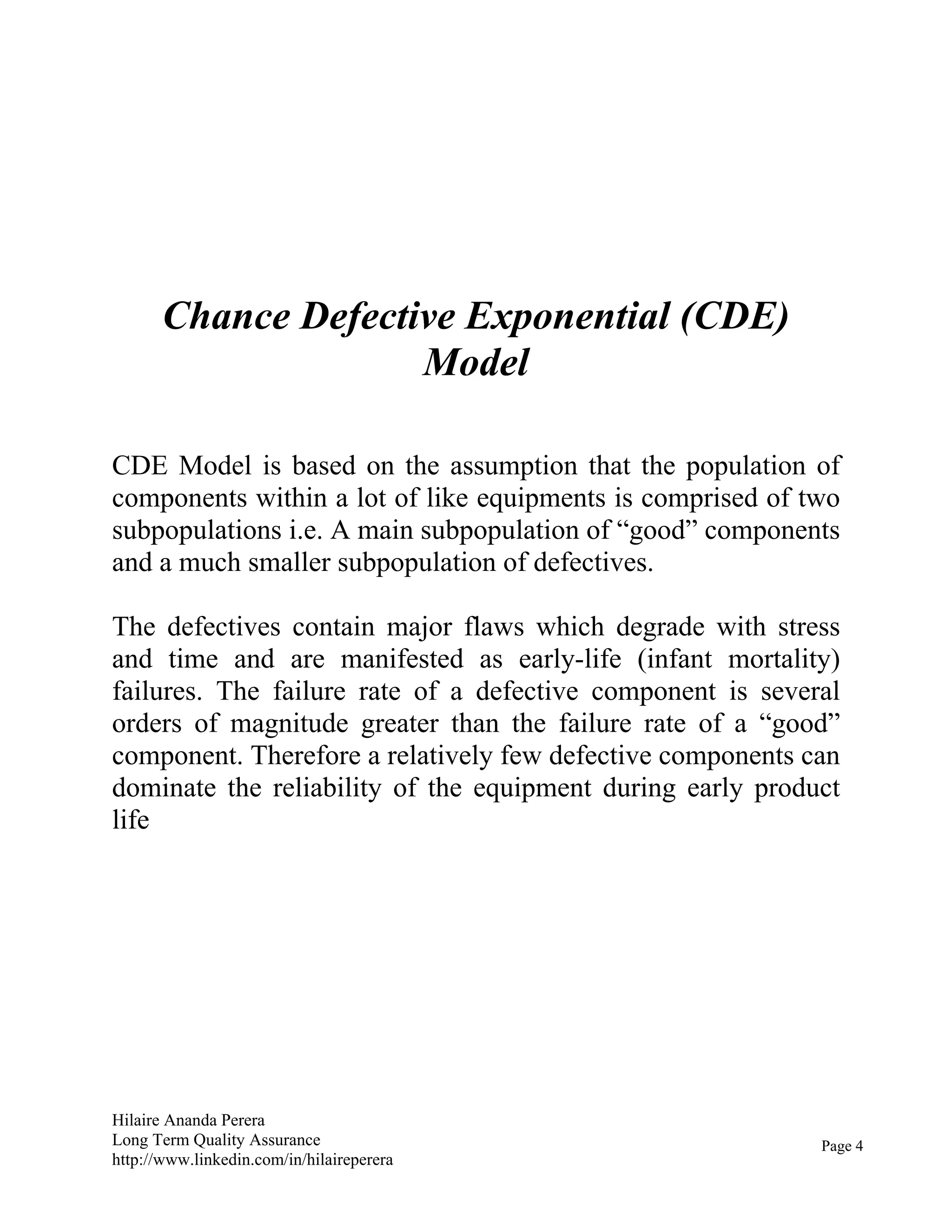

Task Sequence for ESS (Thermal Cycling) Failure Rate Distribution

Analysis to Determine the Best Thermal Cycling Time

ESS Failure Data in

Thermal Cycling

Establish Time To Failure

Data Points (Note 1)

Establish Failure/Time

Distribution

Establish Failure

Rate/Time Distribution

Curve FIT The CDE [A + B*exp(-C*t)] Model

Reference MIL-HDBK-344A

Using SigmaPlot Software Package

Examine the Goodness of Curve Fit Using

Coefficient of Variation (CV) of parameters A,B,C

Determine Time To Remove 99.999% Defects

See

Appendix A

Page 5](https://image.slidesharecdn.com/outgoing1reliabilityassuranceofendunits-151015164214-lva1-app6892/75/Outgoing-Reliability-Assurance-of-End-Units-5-2048.jpg)