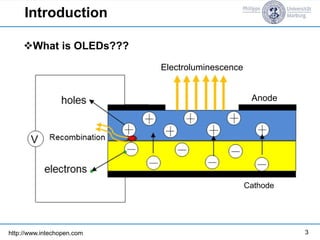

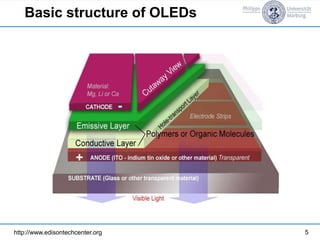

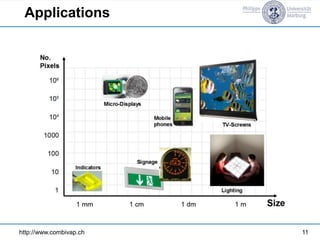

Organic Light Emitting Diodes (OLEDs) are a type of thin-film display that uses organic compounds that emit light when electric current is applied. OLEDs are being developed as a new generation of displays and lighting due to their high contrast, wide viewing angle, and ability to be made flexible. However, OLEDs currently have some limitations including low operating lifetime, high cost, being damageable by water, and difficulty seeing them in direct sunlight. Improvements in materials and manufacturing processes are needed to address these challenges and further advance this promising display technology.