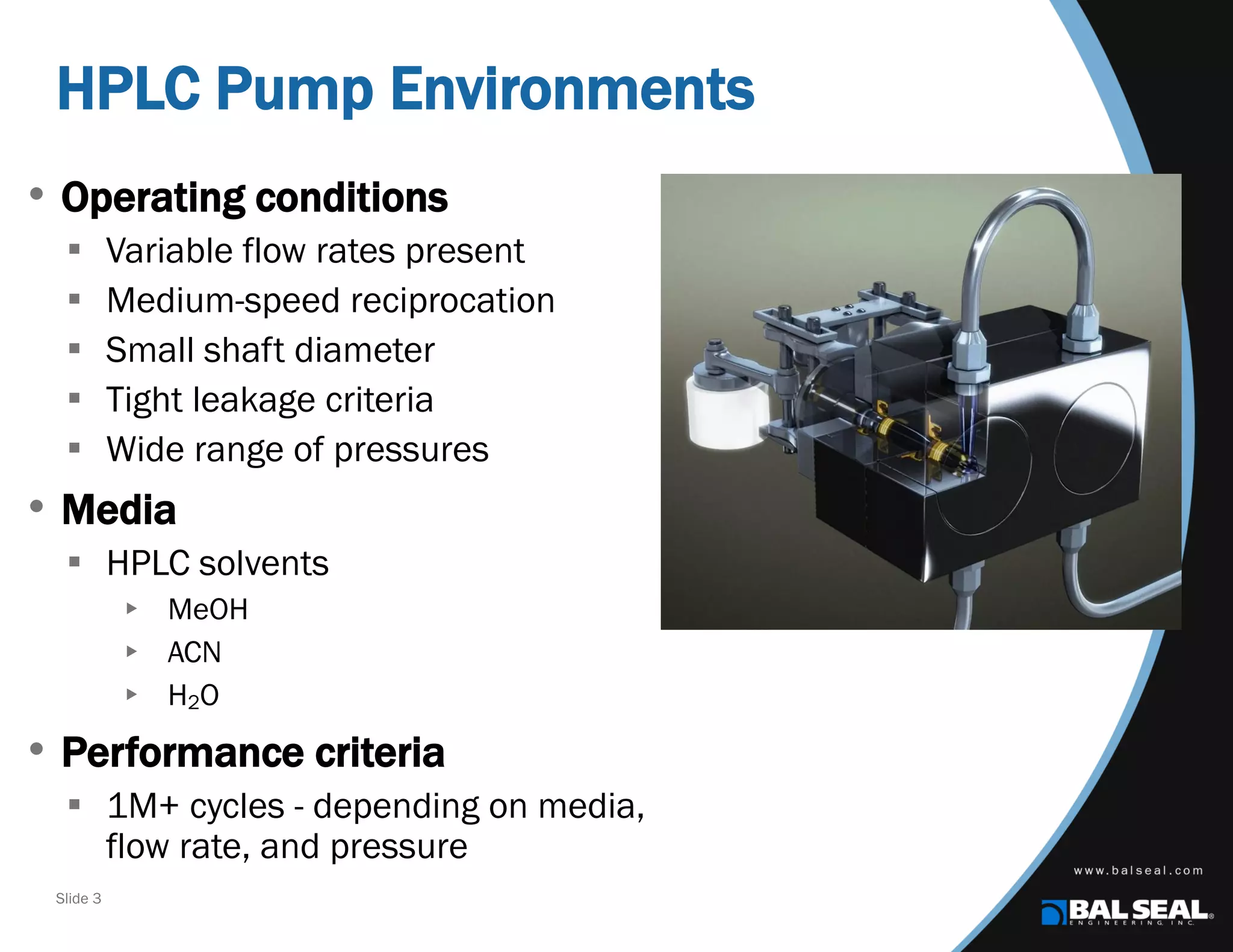

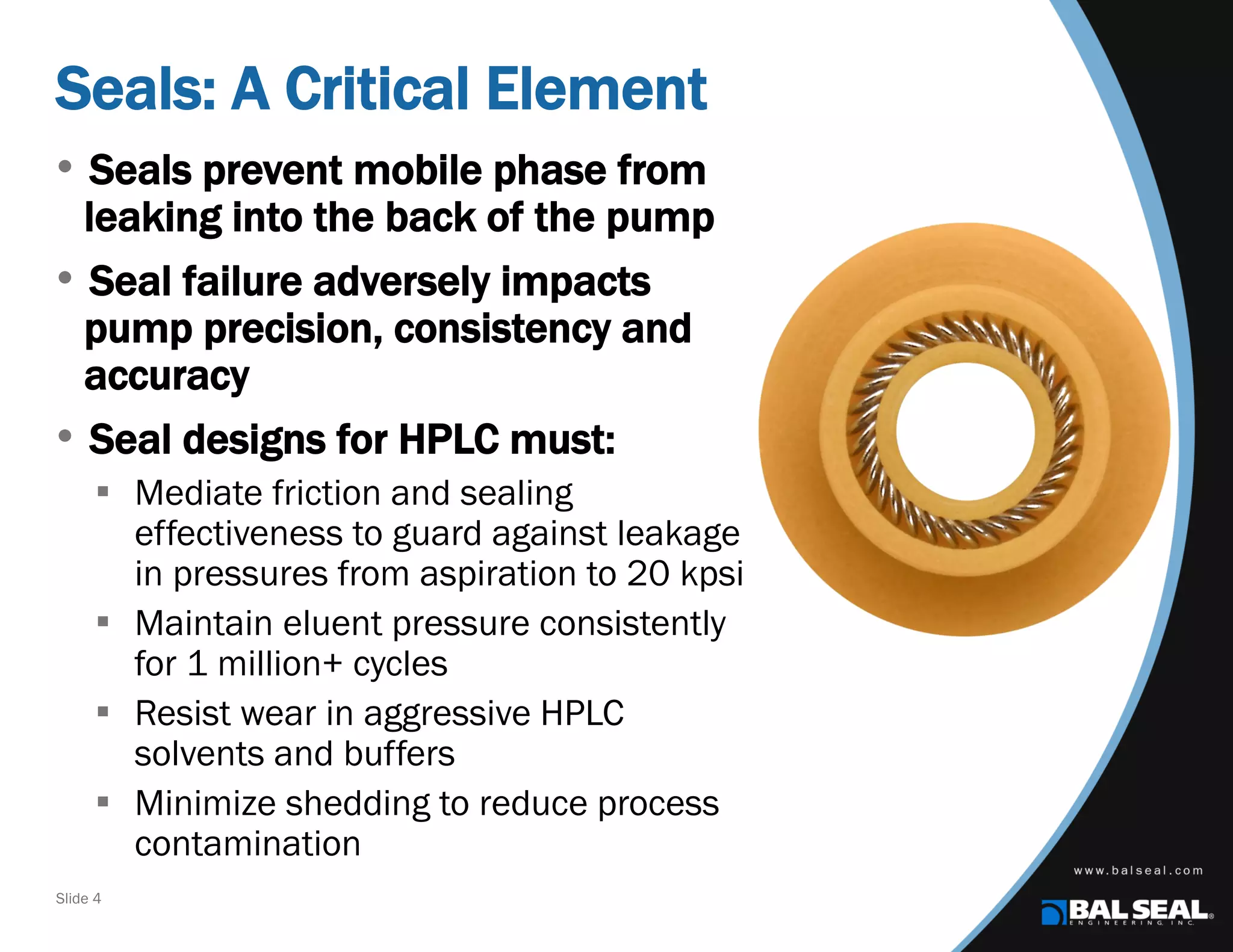

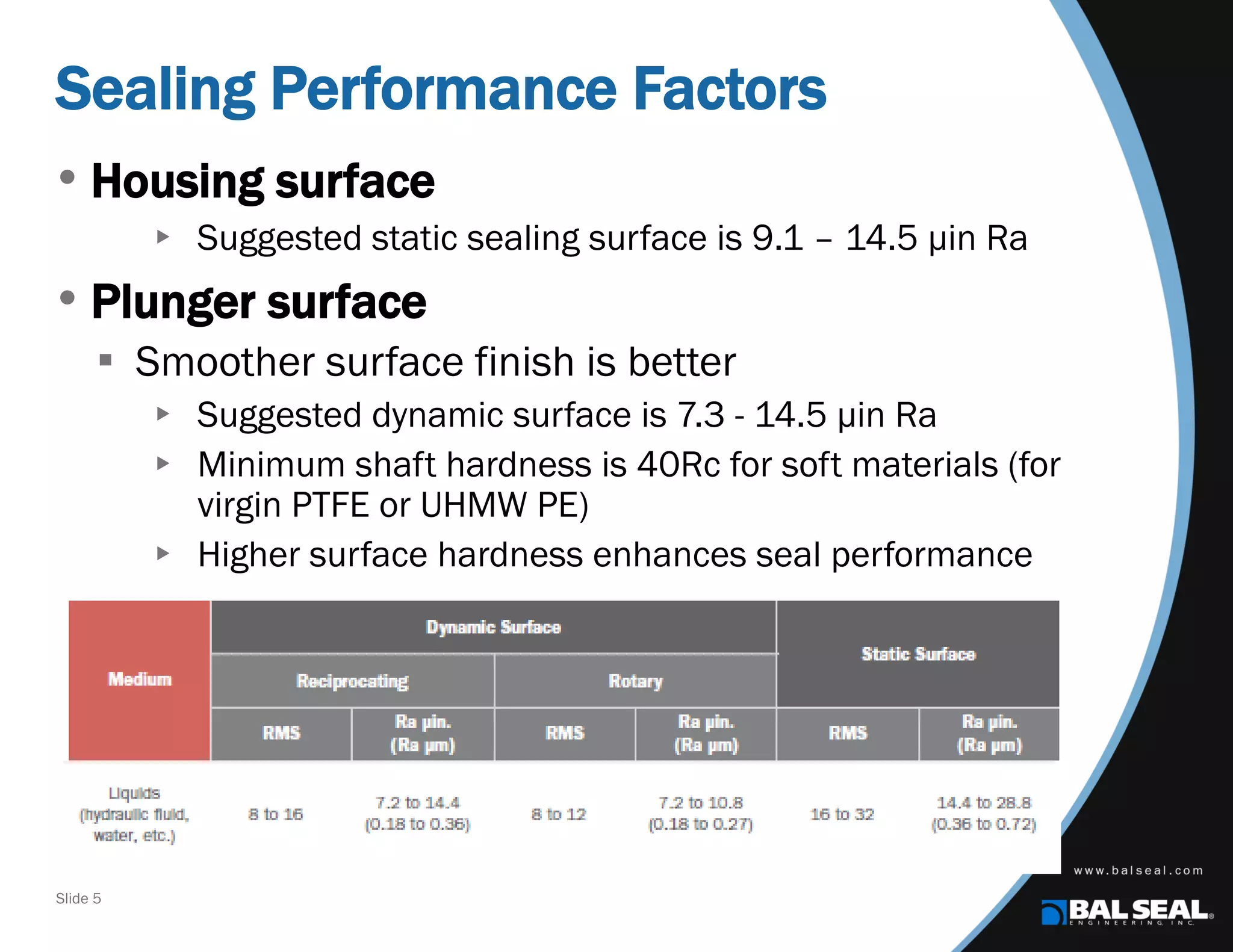

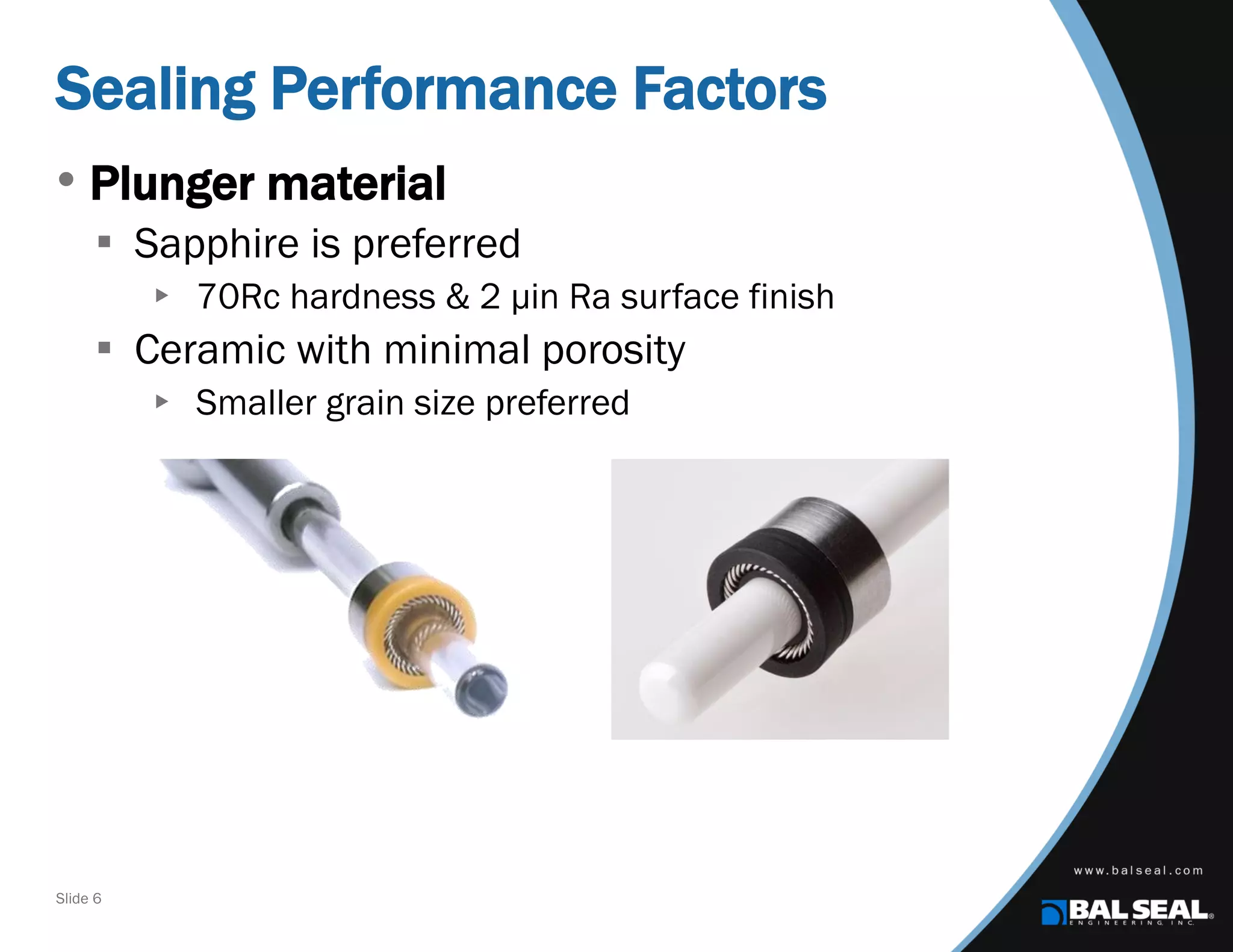

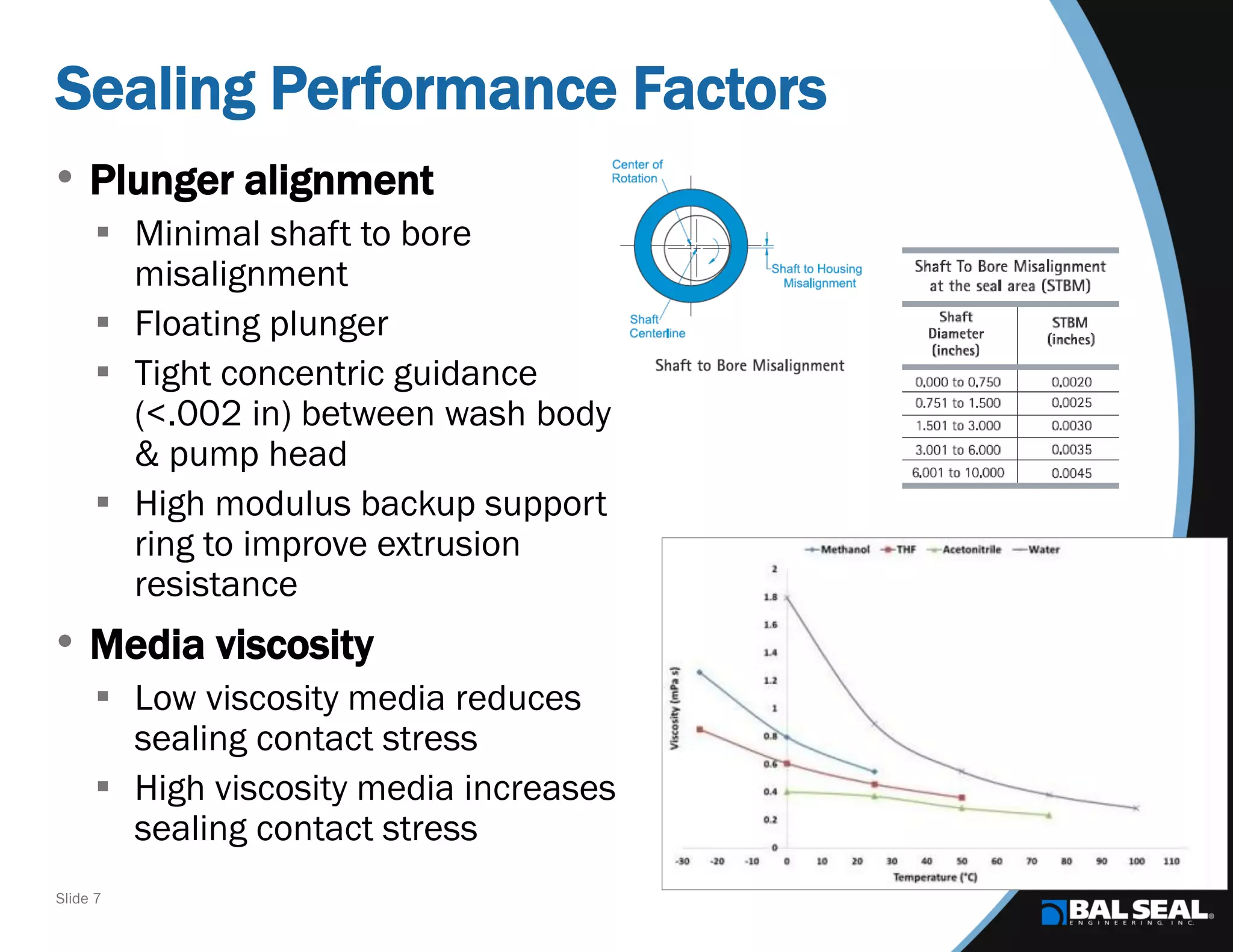

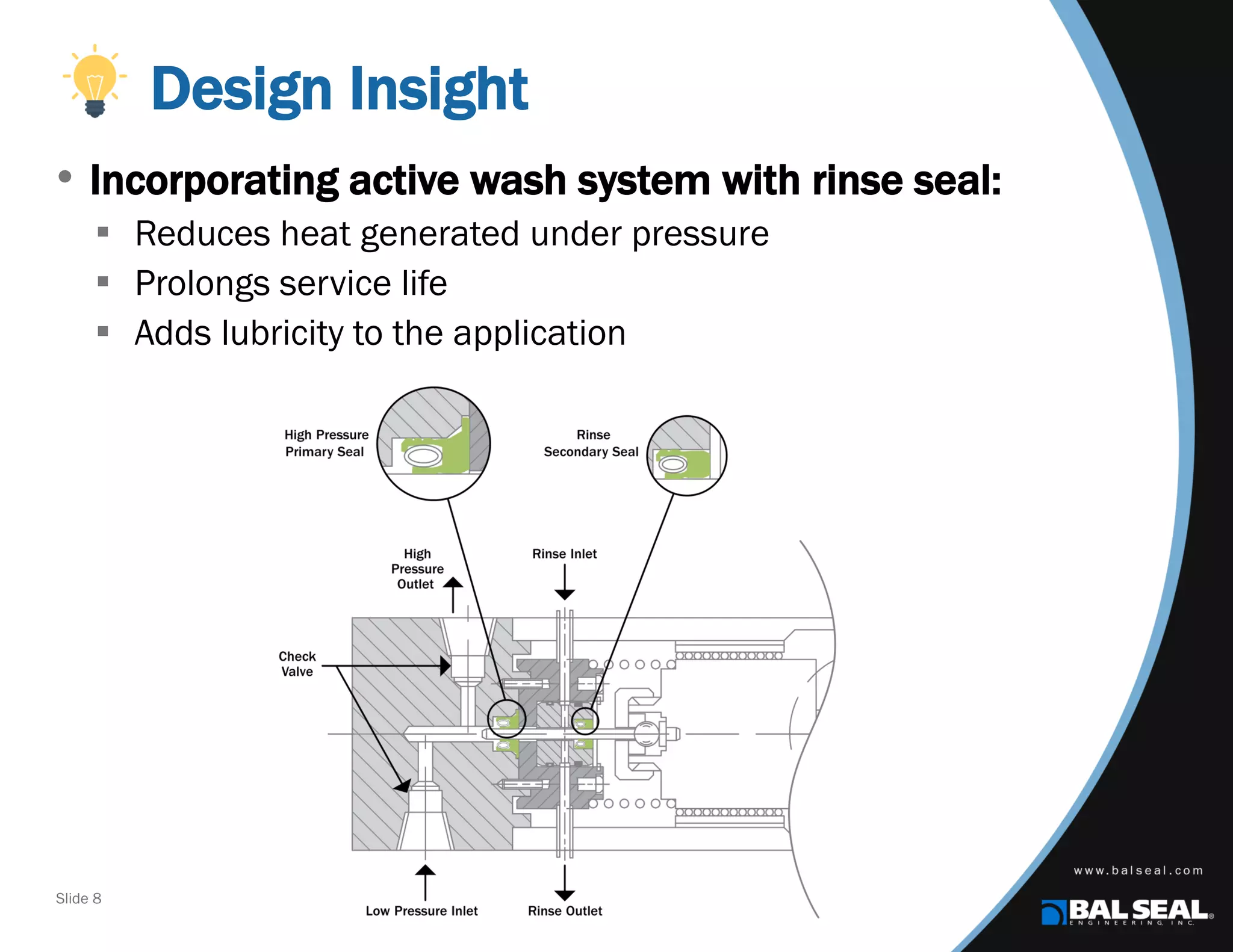

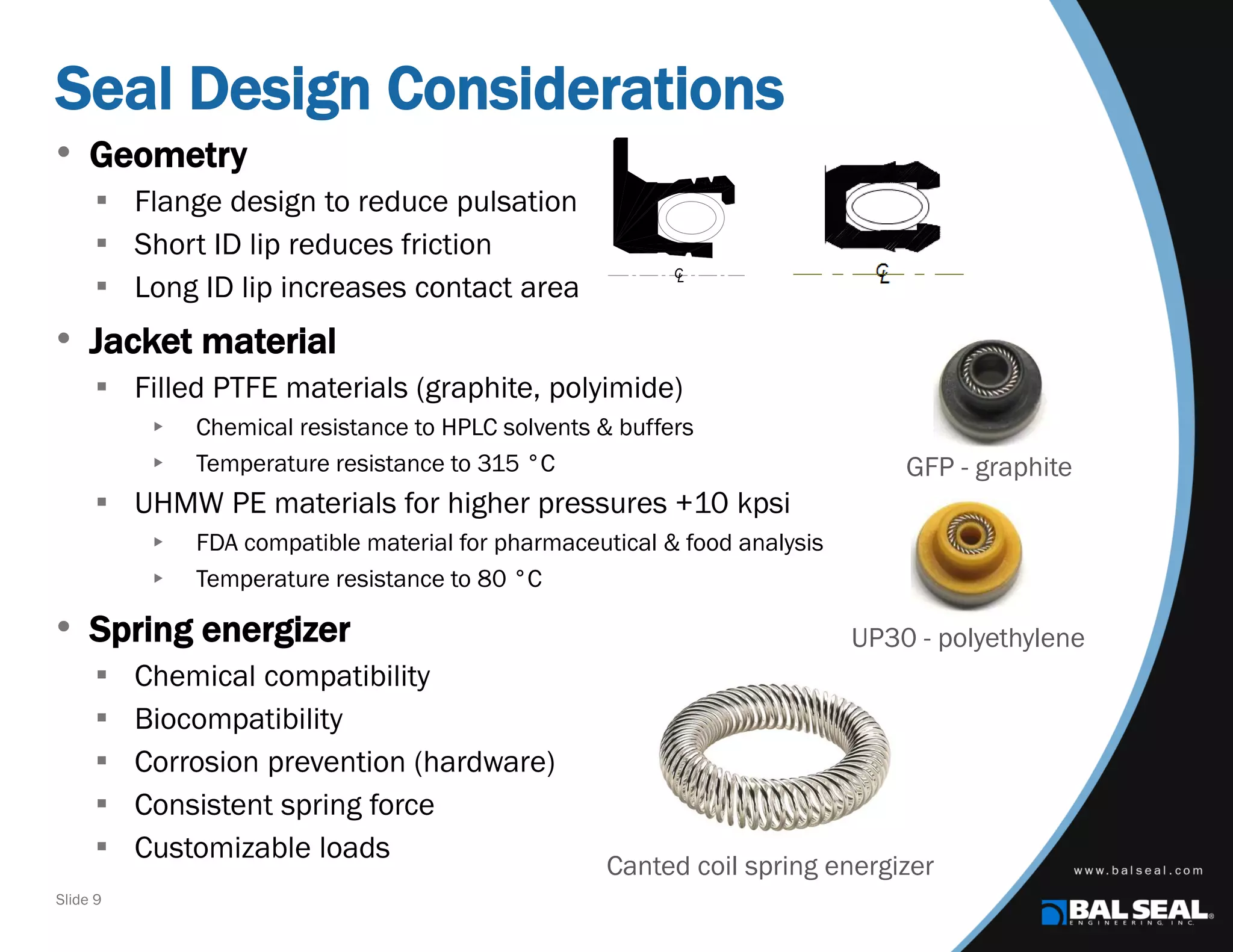

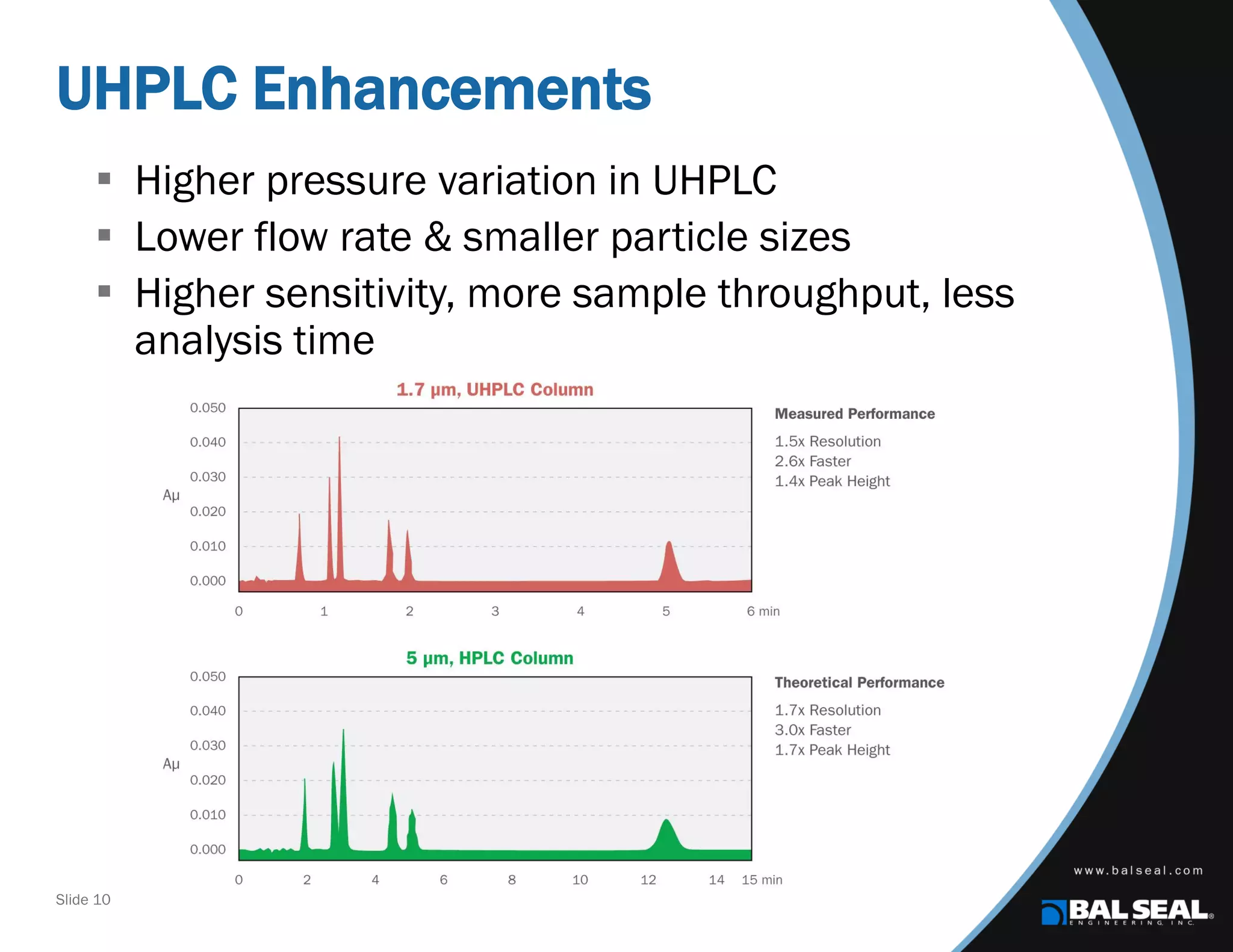

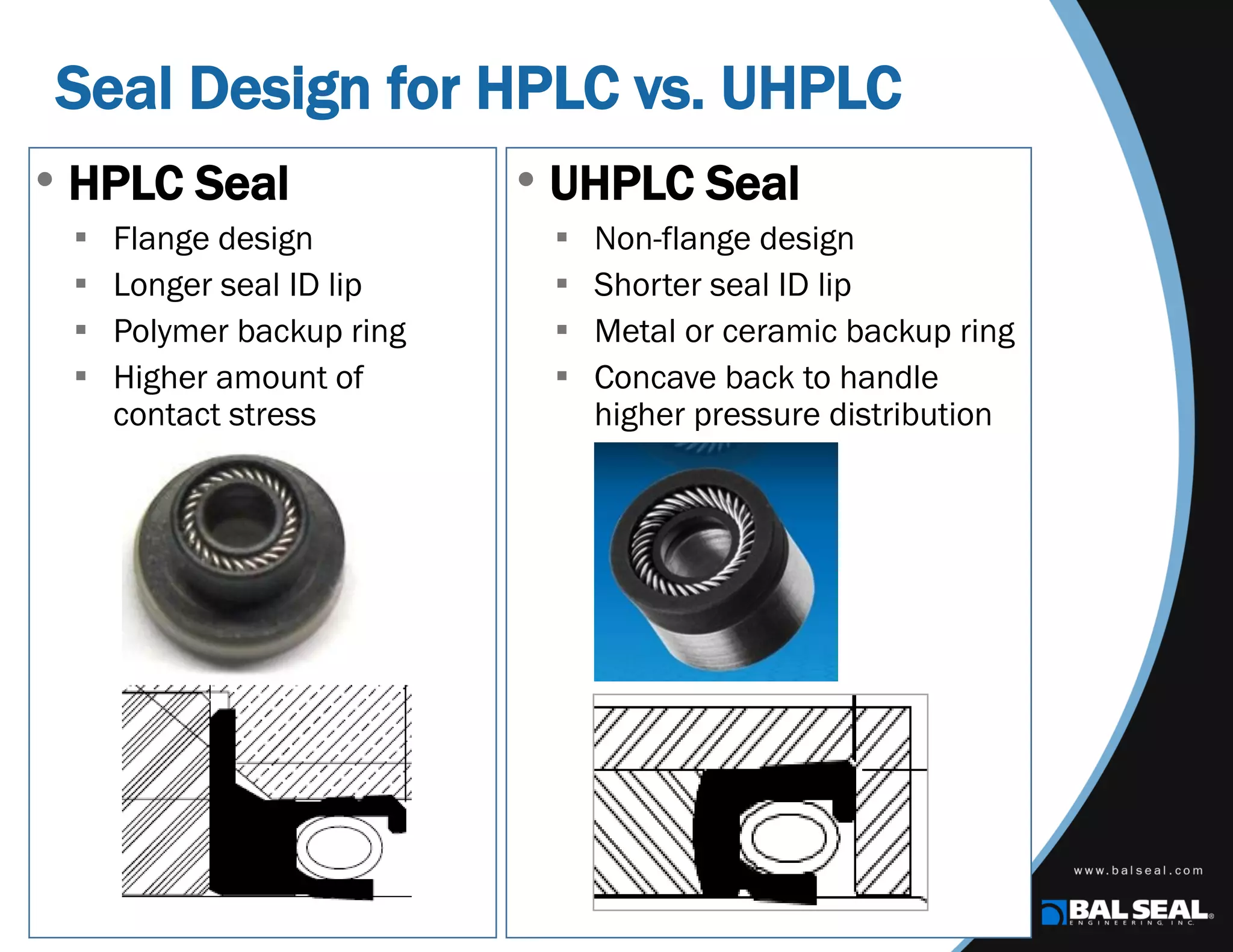

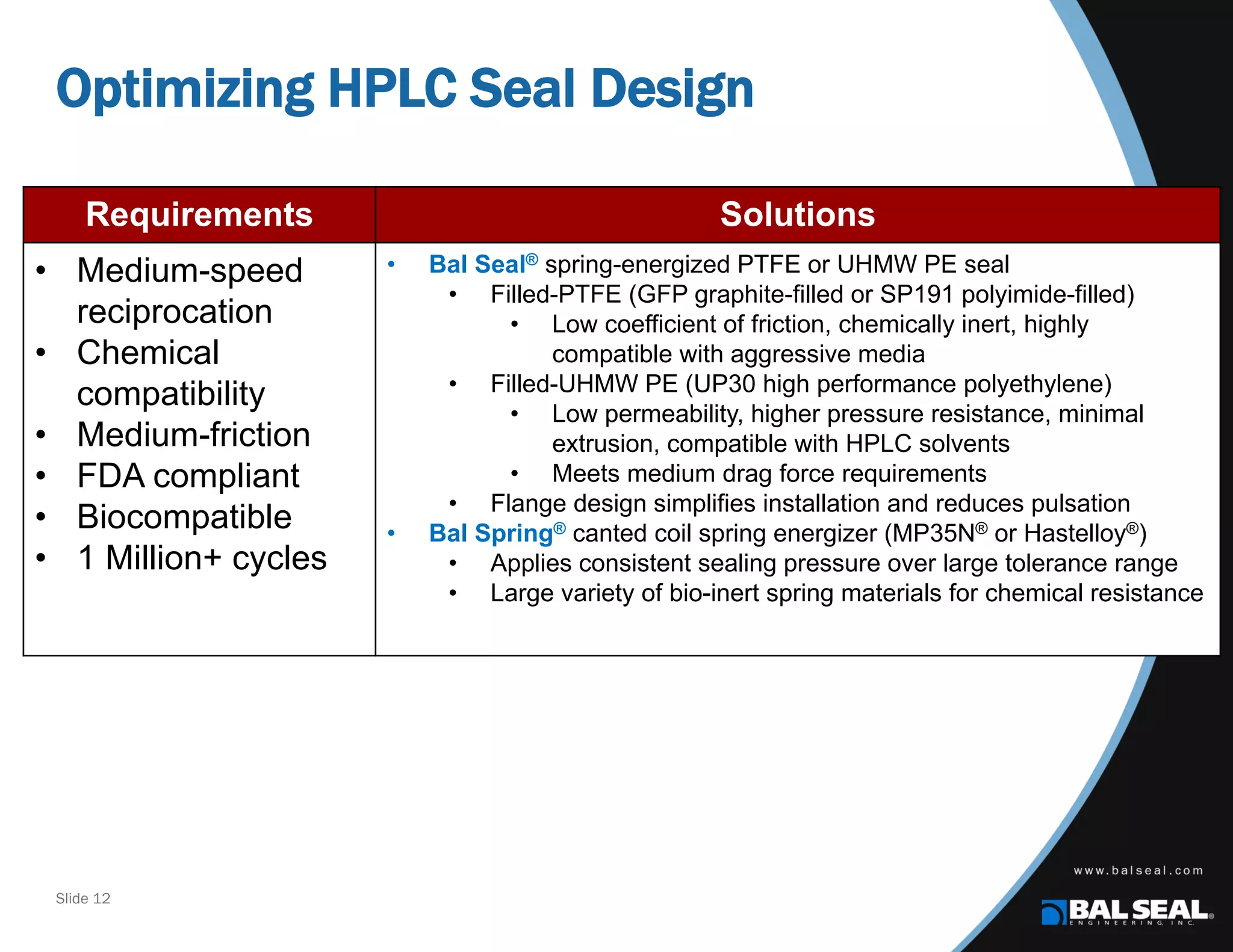

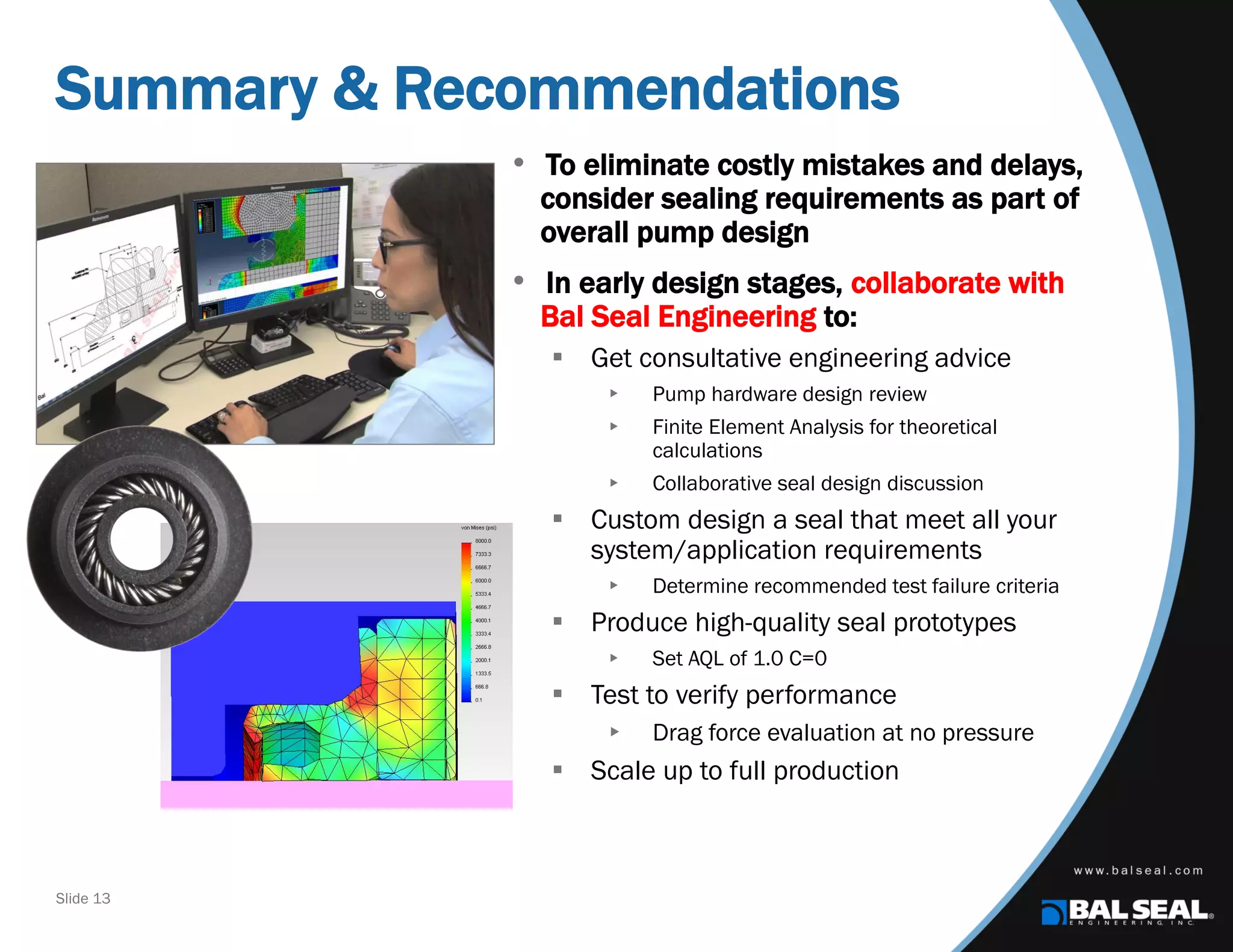

The document discusses optimizing seal design for HPLC (High Performance Liquid Chromatography) and UHPLC (Ultra High Pressure Liquid Chromatography) pumps, highlighting critical performance factors and design insights necessary for preventing leakage and improving pump accuracy. It emphasizes the importance of material choice, alignment, and innovative features like active wash systems to prolong service life and enhance performance. Recommendations are provided for collaboration with Bal Seal Engineering to meet specific sealing requirements and ensure high-quality prototypes.