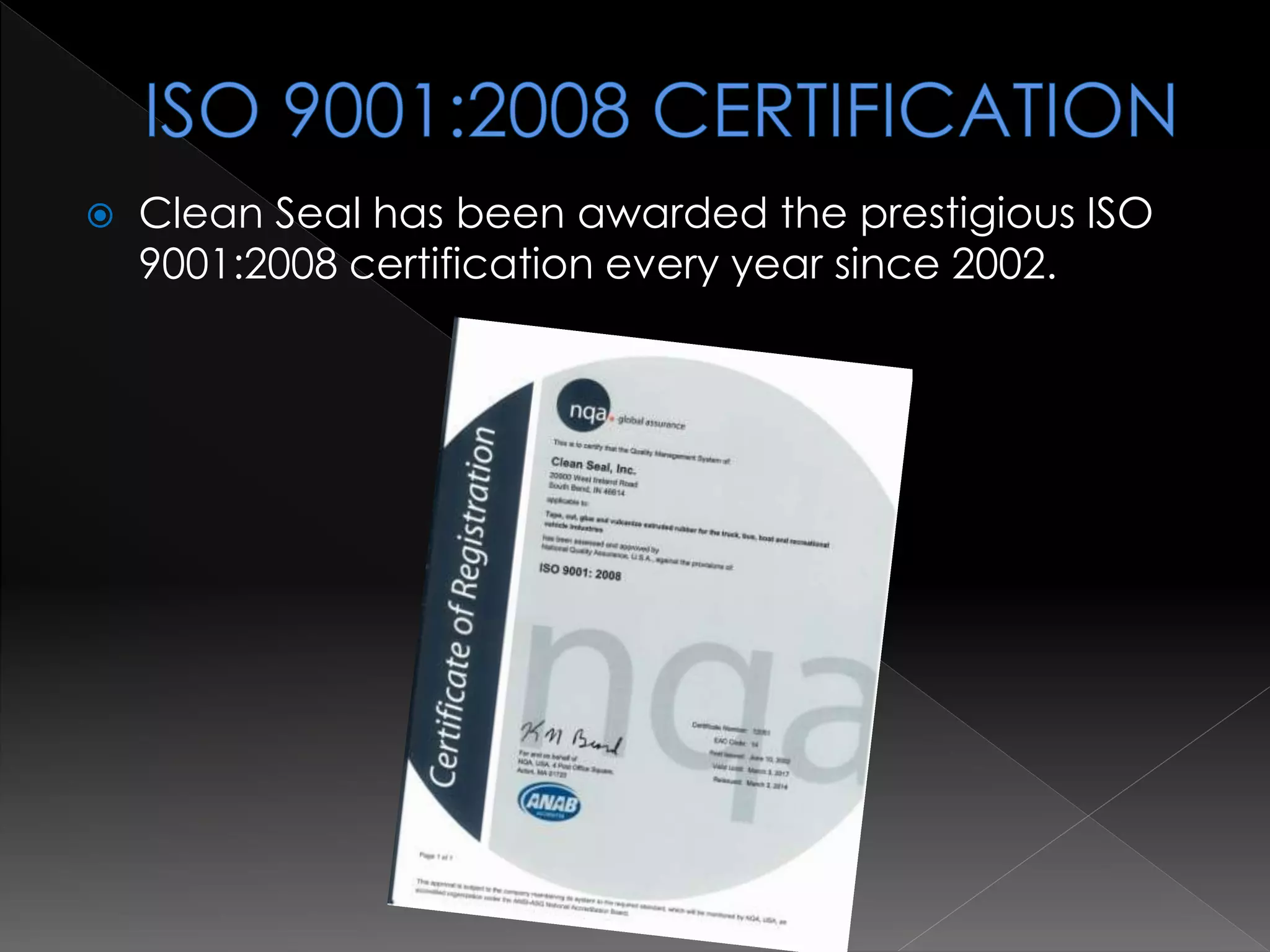

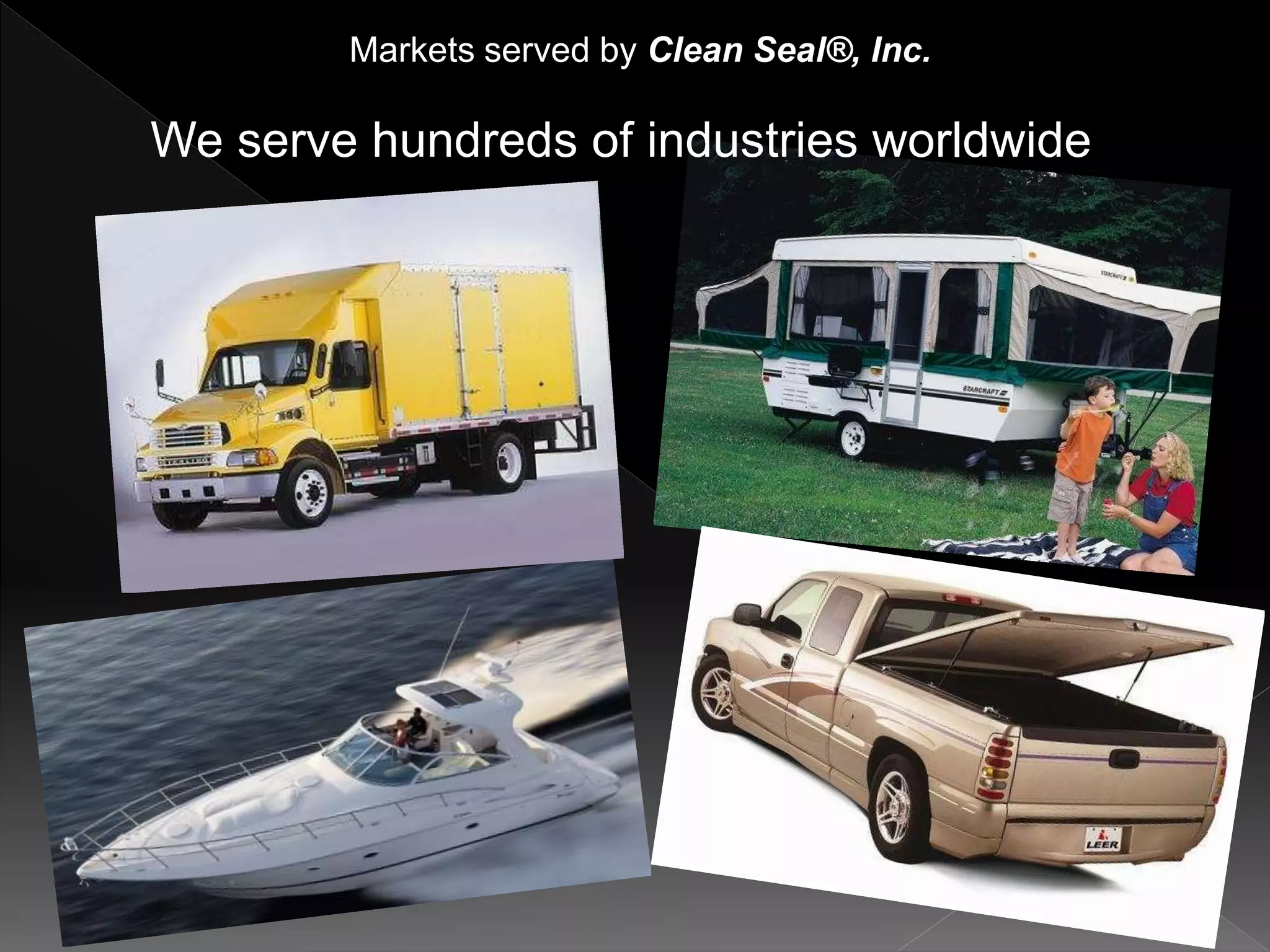

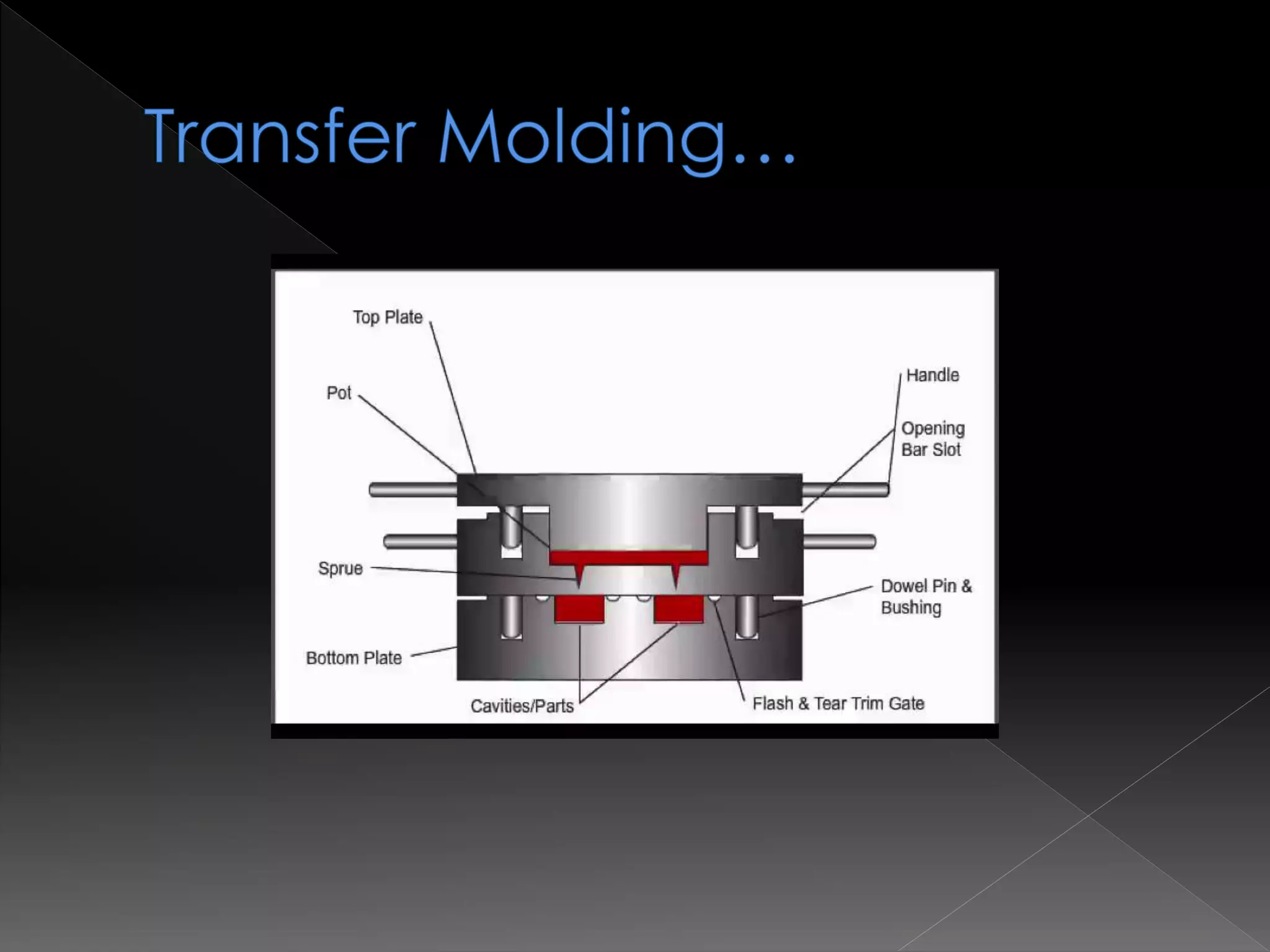

Clean Seal, Inc. has been providing high-quality rubber and plastic molded products since 1978 and has achieved ISO 9001:2008 certification annually since 2002. The company serves a variety of industries with a diverse product line including seals, grommets, bumpers, and custom molded items while emphasizing fast shipping and technical expertise. Located in South Bend, Indiana, Clean Seal focuses on quality assurance and offers solutions tailored to customer needs.