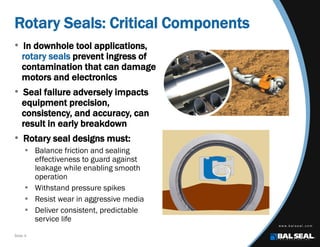

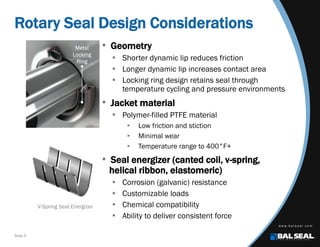

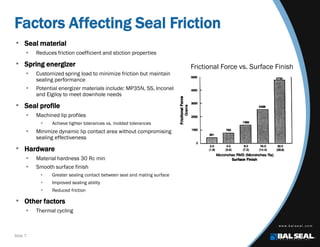

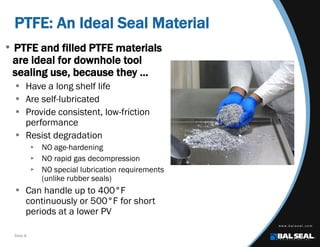

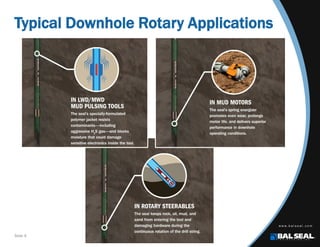

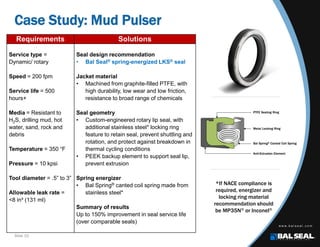

The document discusses the importance of rotary seals in downhole tools, highlighting their role in preventing contamination and ensuring equipment reliability. It outlines design considerations, seal material benefits, and factors affecting performance, including friction and wear resistance. Recommendations for custom seal designs and collaborations with engineering experts are provided to optimize downhole equipment performance.