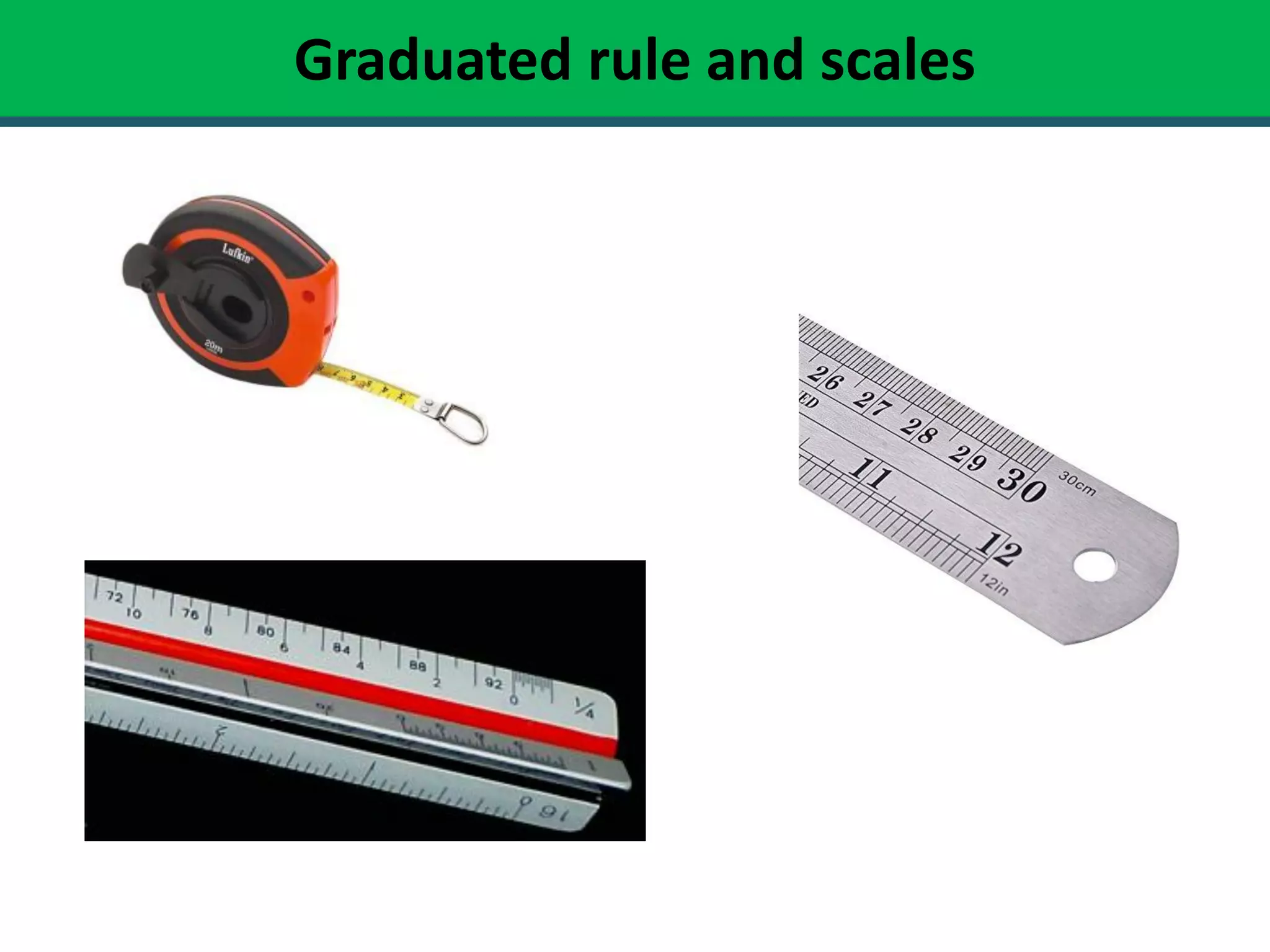

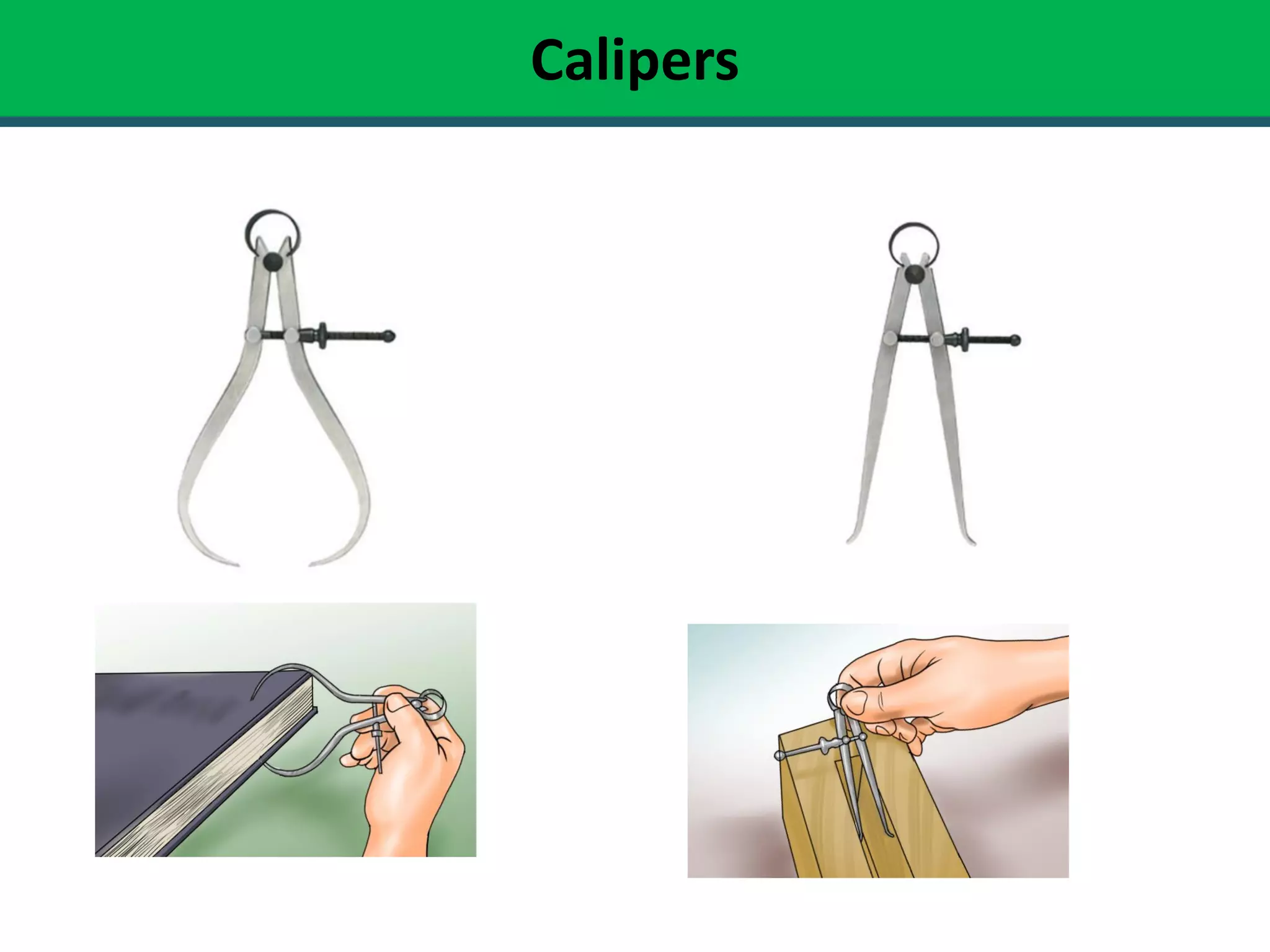

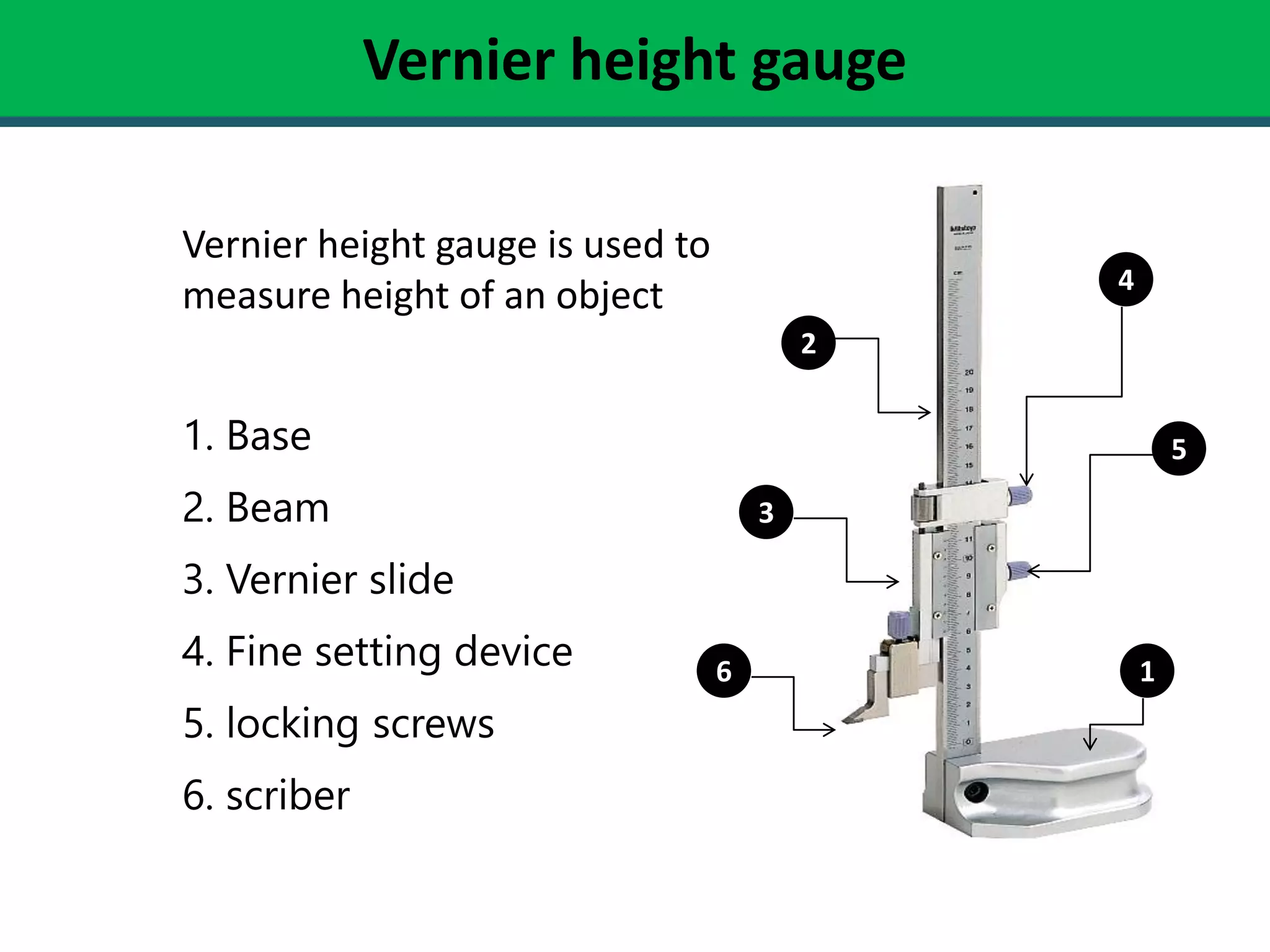

This document discusses various linear measurement instruments used in engineering. It begins by classifying linear measurement devices into low, medium, and high resolution. Low resolution devices include graduated rules and calipers. Medium resolution devices discussed are vernier calipers, micrometers, and dial gauges. High resolution devices able to measure to within microns include slip gauges and comparators. The document provides detailed descriptions and examples of how each of these tools is used to perform precise linear measurements.