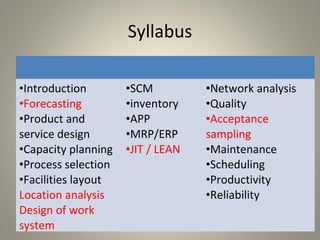

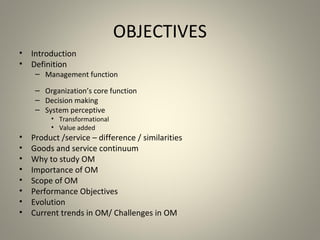

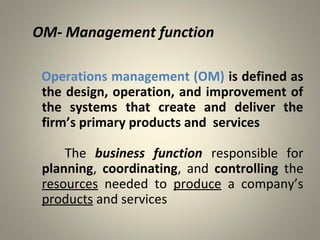

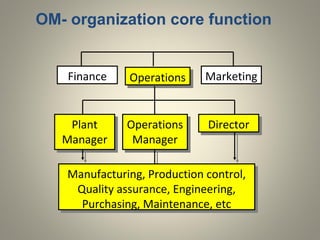

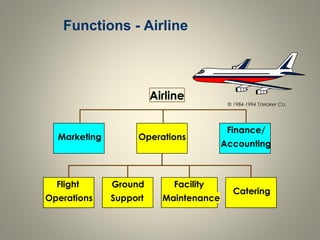

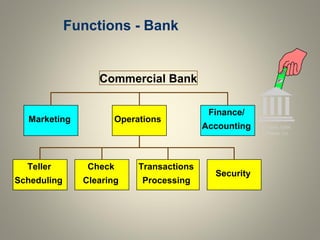

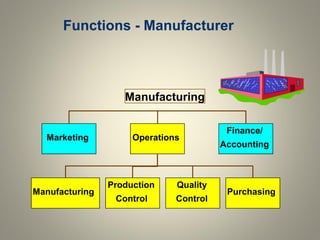

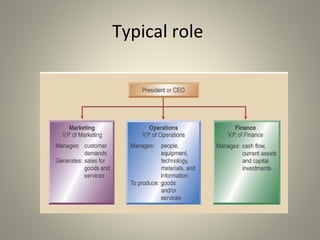

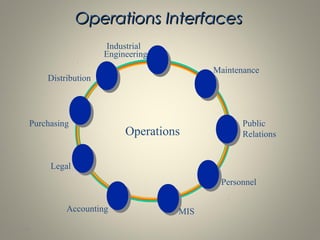

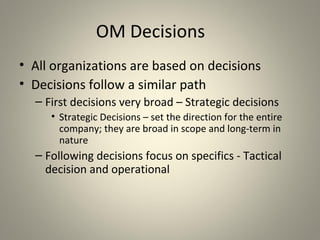

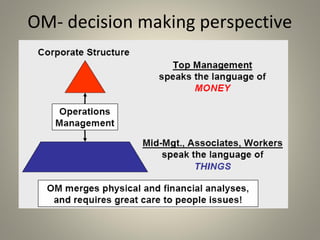

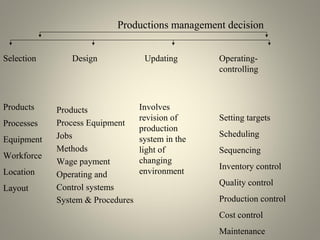

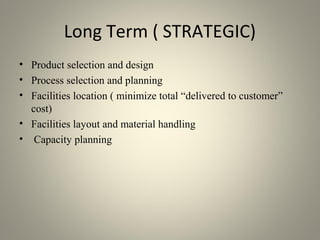

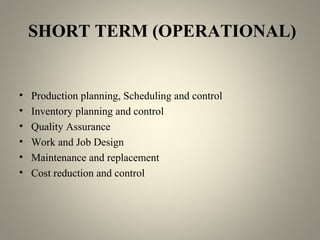

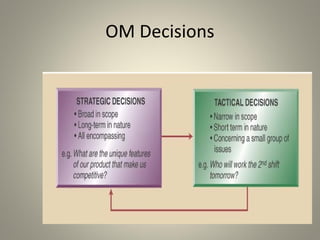

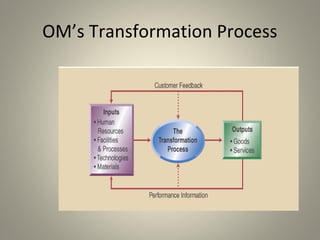

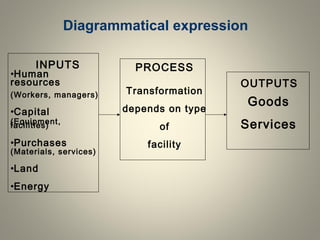

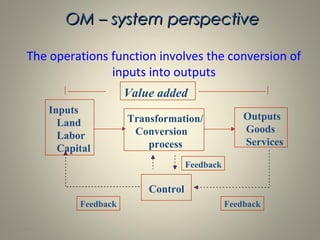

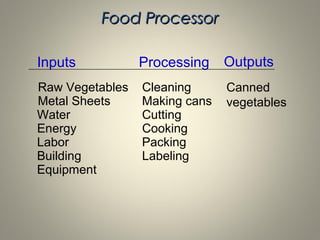

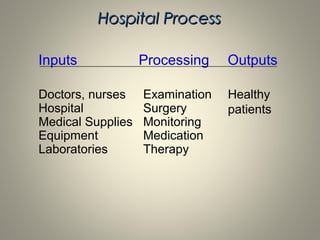

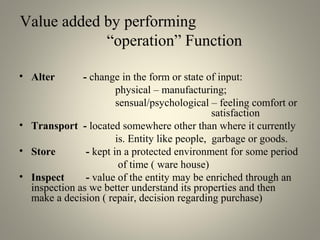

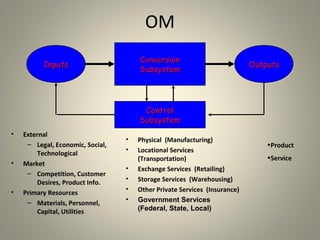

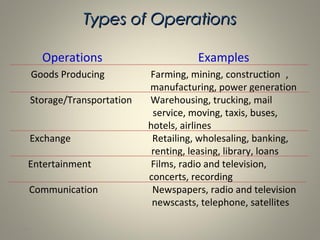

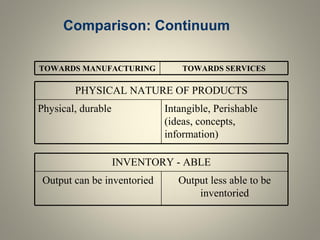

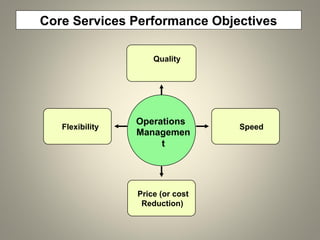

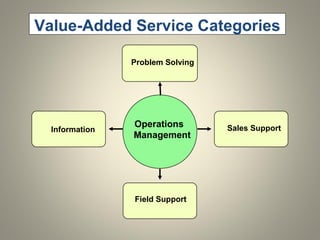

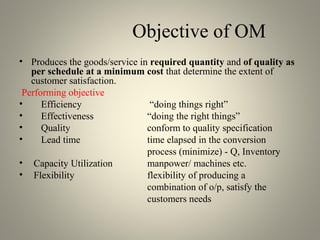

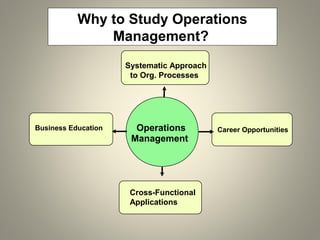

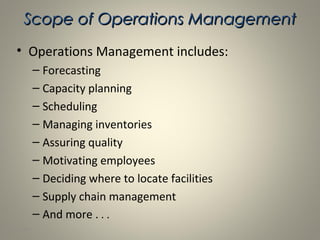

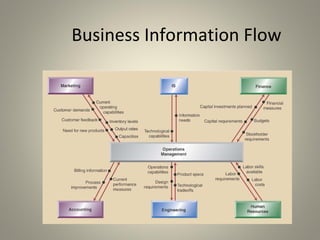

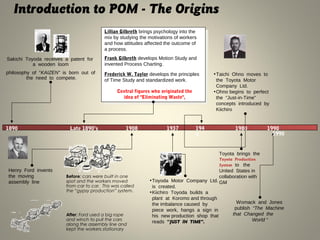

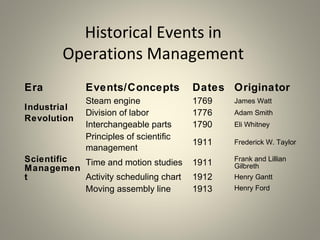

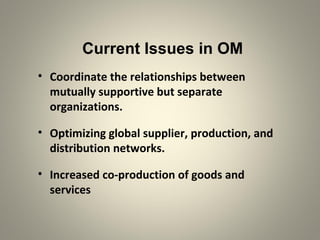

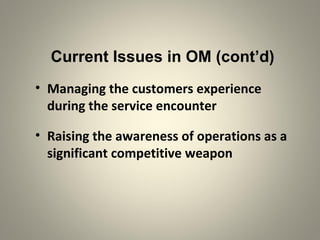

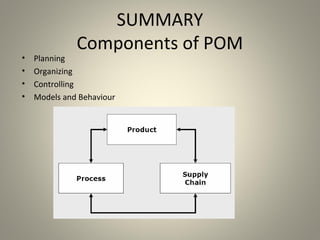

Operations management is responsible for managing the transformation of inputs into outputs through efficient and effective planning, controlling, and decision making. It involves decisions ranging from strategic to tactical levels. Key aspects of operations management include production planning, quality control, inventory management, and facility location and layout. Operations management is important for both manufacturing and service organizations.