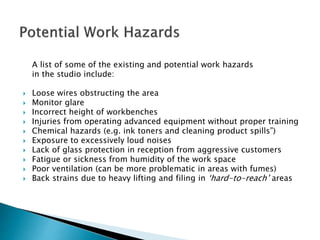

The document outlines various workplace health and safety policies and procedures for a company, including identifying potential work hazards, establishing an incident reporting process, inspecting the work environment, and outlining employer and employee rights and responsibilities for occupational health and safety. It also lists various job positions available in the company and provides resources for occupational health and safety guidelines.