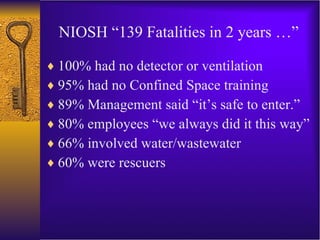

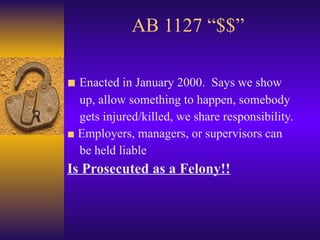

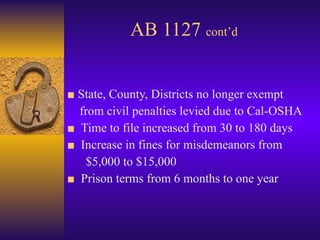

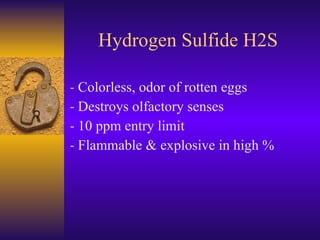

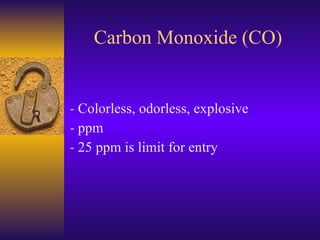

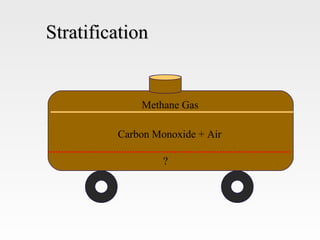

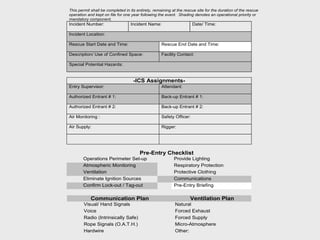

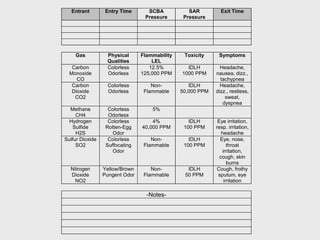

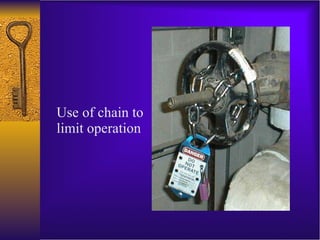

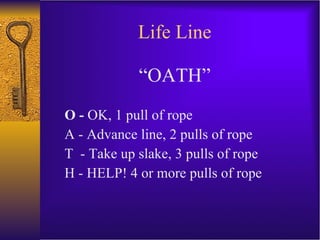

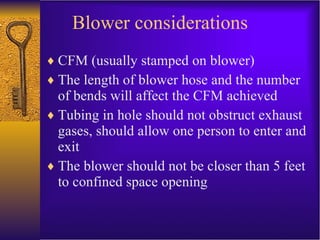

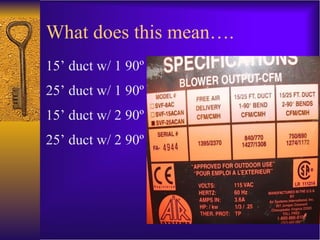

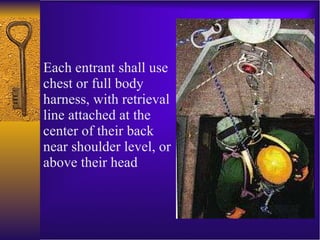

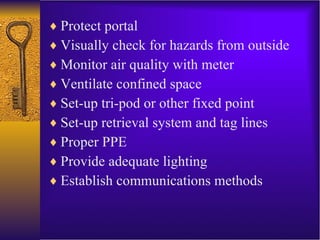

The document provides an overview of confined space awareness and rescue. It defines a confined space and permit-required confined space. It discusses hazards such as hazardous atmospheres, engulfment, and entrapment. It outlines the history of confined space fatalities, regulations including OSHA and NFPA standards, required training and equipment for confined space entry and rescue, atmospheric monitoring, ventilation, communication methods, and rescue considerations.