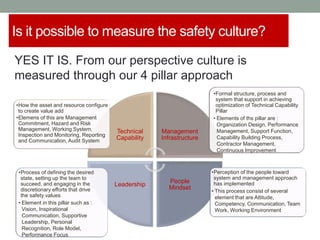

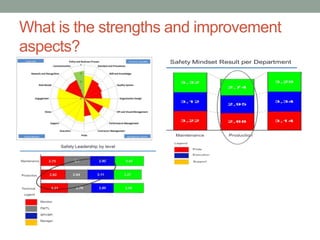

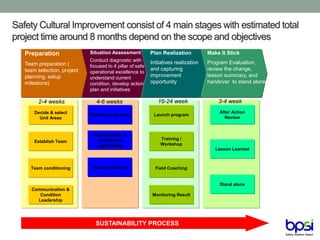

This document discusses safety culture and how to measure and improve it. It defines safety culture as how people think, believe, intend and behave regarding safety. Developing a strong safety culture can sustain safe behaviors because people want it and believe in it. There are four pillars to measure safety culture: technical capability, management infrastructure, people mindset, and leadership. Methods to measure include document review, interviews, surveys, and observations. Measuring safety culture identifies areas for improvement and encourages continuous progress. The document outlines four options to improve safety culture: conducting a safety culture survey, a full diagnostic, a cultural improvement program, and ensuring sustainability of gains.