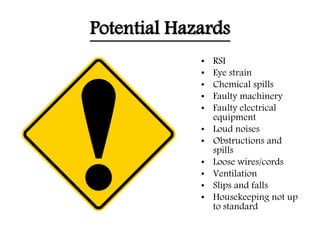

The document outlines the induction process for new employees which includes discussing workplace policies, safety procedures, emergency evacuations, and providing any necessary equipment or training. It details current safety procedures around equipment testing, chemical storage, personal protective equipment, and incident reporting. Potential workplace hazards like faulty equipment, chemicals, and slips are identified. The responsibilities of both employees and employers for health and safety are also covered.