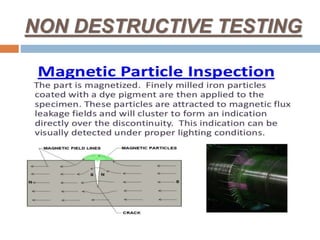

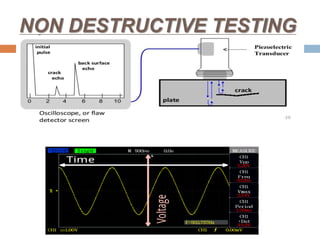

Non-destructive testing (NDT) is a maintenance engineering technique used to analyze materials and components for properties and faults without damaging them. Common NDT methods include visual testing, dye penetrant testing, ultrasonic testing, and radiography testing, each utilizing different technologies and approaches to detect internal or surface flaws. Ultrasonic testing, for instance, uses high-frequency sound waves for high accuracy in flaw detection and minimal preparation requirement.