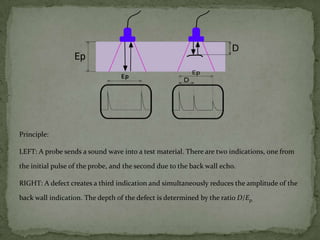

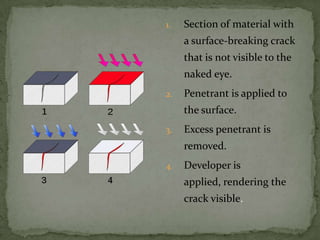

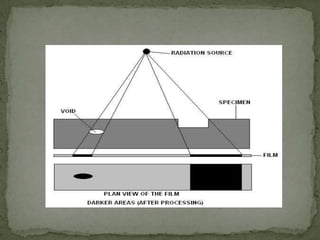

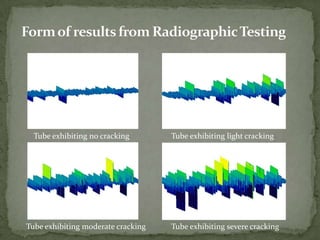

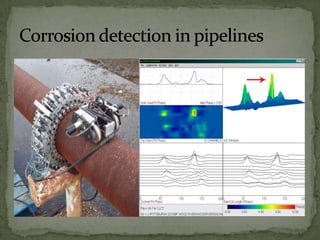

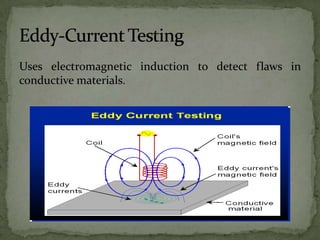

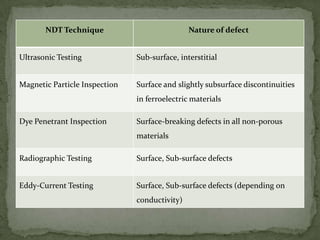

This document discusses nondestructive testing (NDT), which is a group of analysis techniques used in science and industry to evaluate materials, components, or systems without causing damage. Various NDT methods rely on electromagnetic radiation, sound, or inherent material properties to examine samples for flaws. Common NDT techniques mentioned include ultrasonic testing, magnetic particle inspection, dye penetrant inspection, radiographic testing, and eddy-current testing. These techniques are widely used across various industries such as aerospace, mechanical, civil, and electrical engineering.