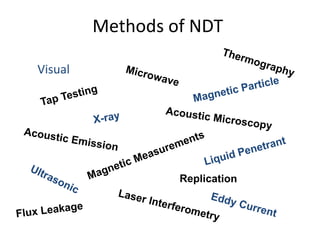

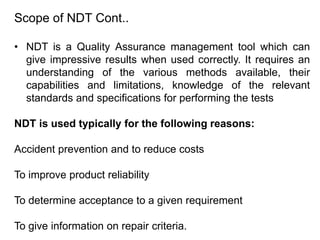

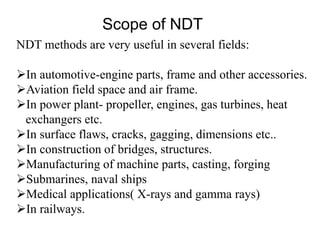

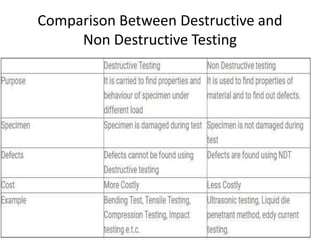

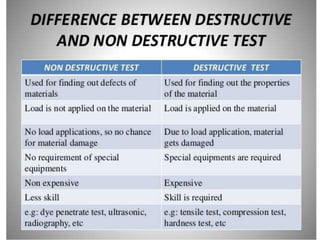

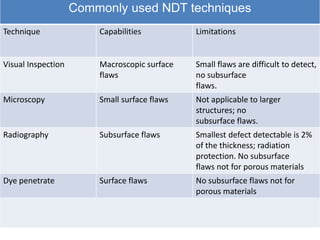

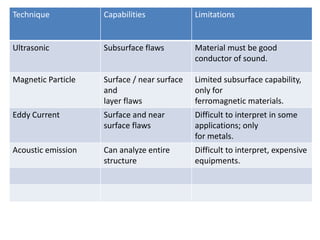

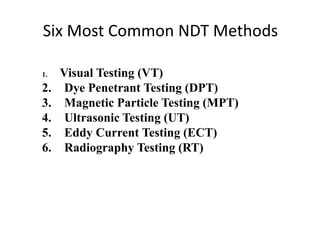

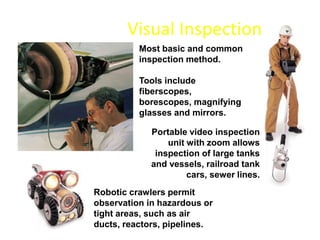

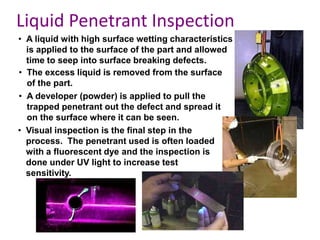

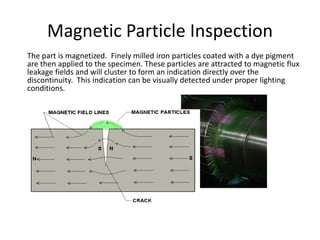

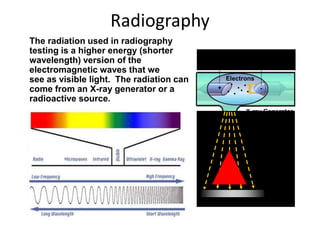

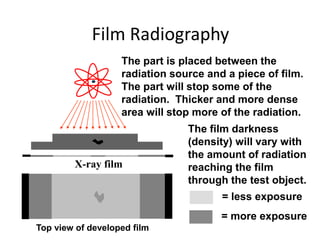

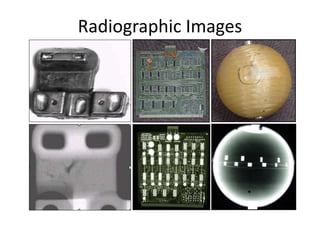

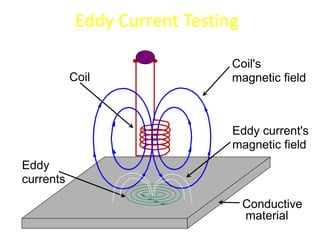

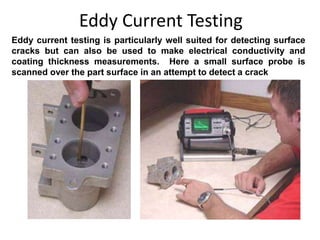

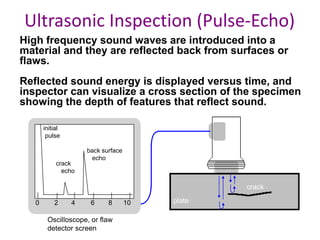

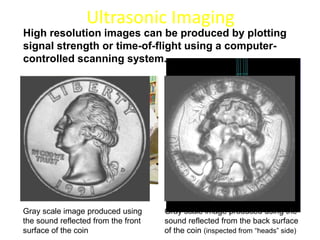

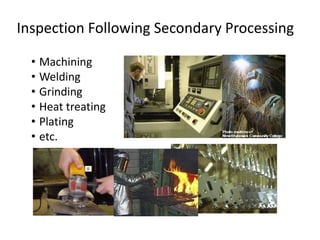

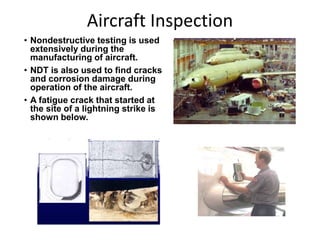

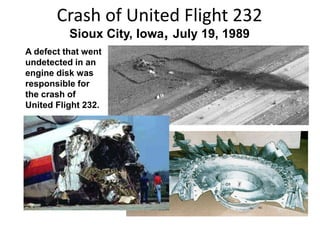

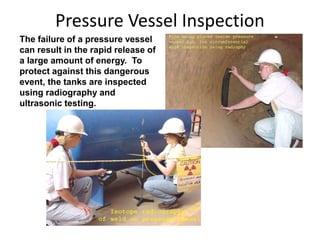

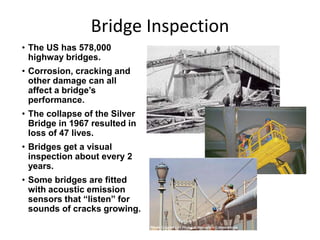

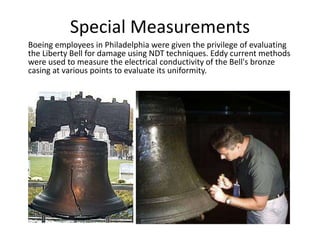

This document provides an introduction to non-destructive testing (NDT). It defines NDT as using noninvasive techniques to inspect materials and components without damaging them. The document outlines six common NDT methods - visual testing, liquid penetrant testing, magnetic particle testing, ultrasonic testing, eddy current testing, and radiography. It provides details on the basic principles, equipment, and applications of each method. The document also discusses the advantages of NDT, its various applications across industries like aviation, oil and gas, and construction, and important terminology used in NDT.