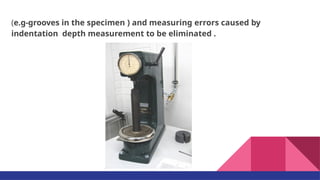

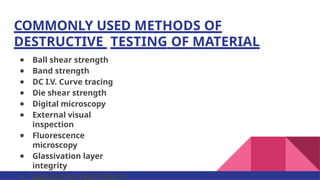

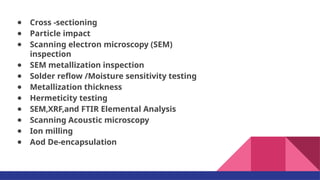

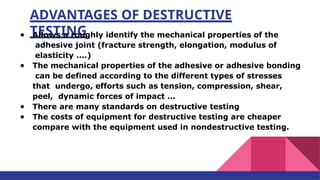

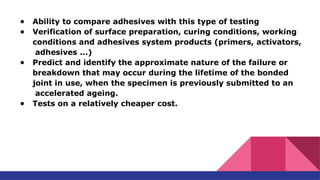

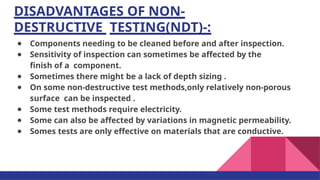

The document provides an overview of destructive testing (DT) and non-destructive testing (NDT) methods, including their types, advantages, and disadvantages. Destructive testing examines a specimen's behavior until failure, while non-destructive testing evaluates materials without causing damage. Both methods serve critical roles in assessing material properties and ensuring structural integrity in various applications.