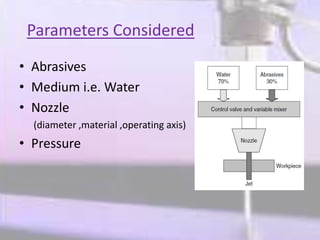

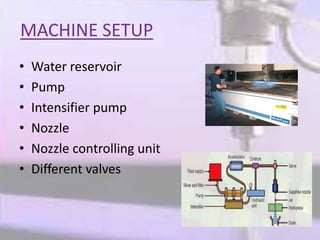

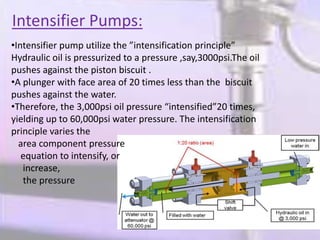

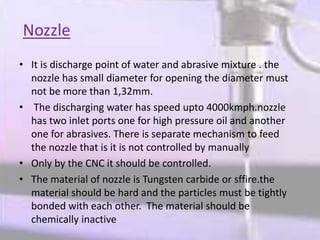

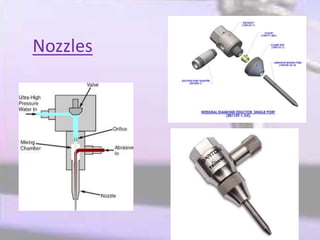

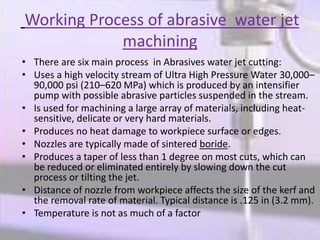

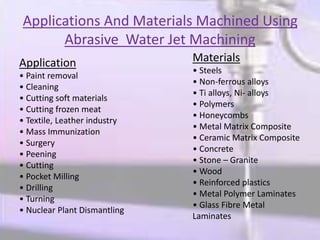

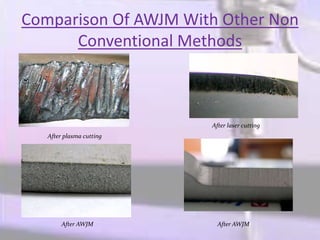

The document discusses abrasive waterjet machining (AWJM), a non-conventional machining process. It provides a brief history of AWJM, describing how abrasives were added to waterjets in the 1970s to allow cutting of harder materials. The key components of an AWJM system are described, including water reservoirs, intensifier pumps to generate ultra-high water pressures, multi-axis motion systems, and abrasive-fed nozzles. Advantages are clean cutting with minimal heat impact and ability to cut a wide range of materials efficiently. Disadvantages include high operating costs for hard materials and inability to cut very thick parts. The document outlines applications and provides comparisons to other non-conventional machining methods.