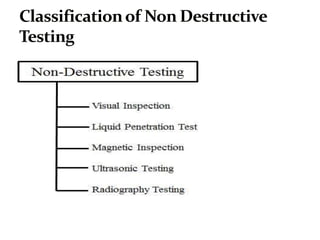

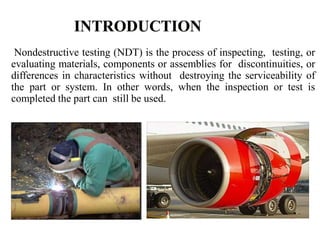

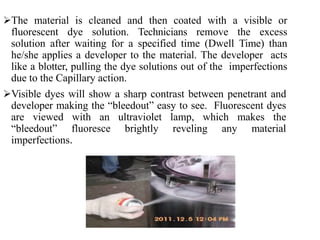

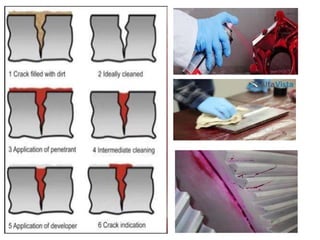

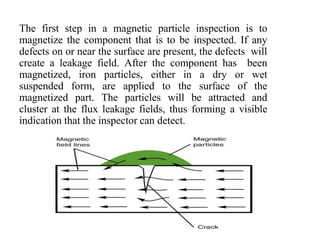

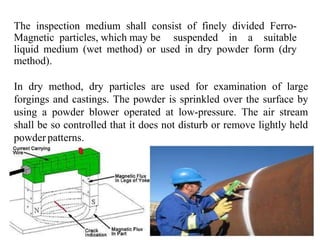

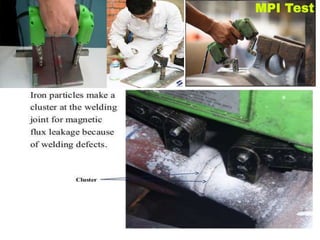

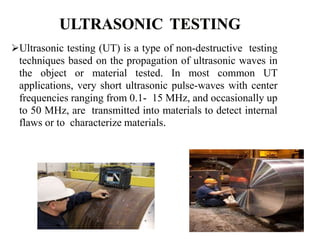

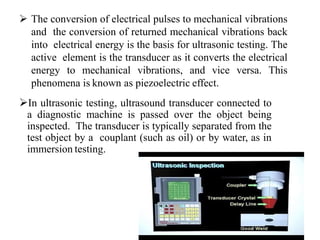

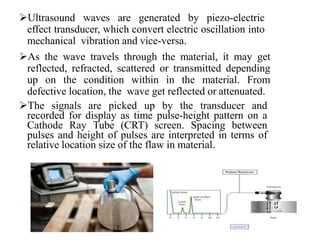

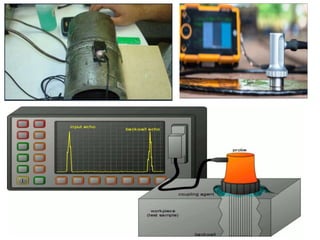

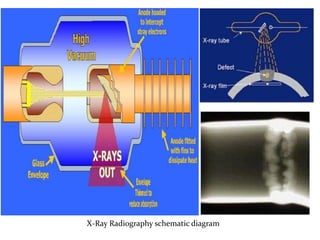

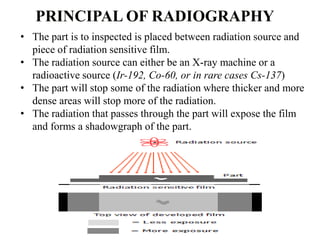

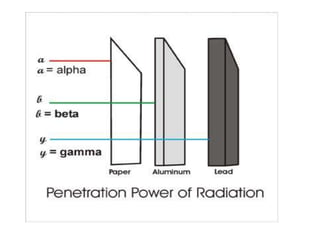

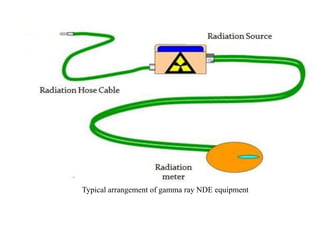

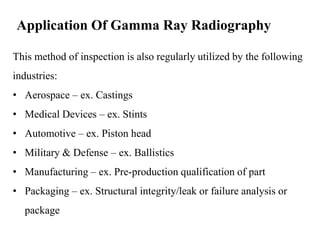

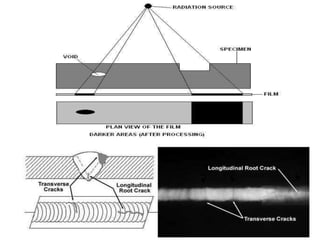

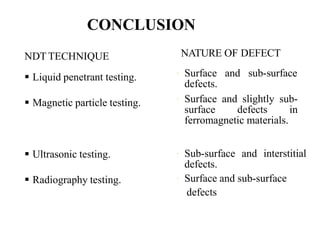

The document discusses various non-destructive testing techniques used to inspect materials and components without damaging them. It describes liquid penetrant testing which uses dyes to detect surface defects, magnetic particle testing which uses magnetic fields to find surface and subsurface flaws in ferromagnetic materials, ultrasonic testing which uses ultrasonic pulses to characterize materials and locate internal defects, and radiographic testing which uses x-rays or gamma rays to create images of internal structures and defects. The document provides details on the equipment, procedures, advantages and limitations of each non-destructive testing method.