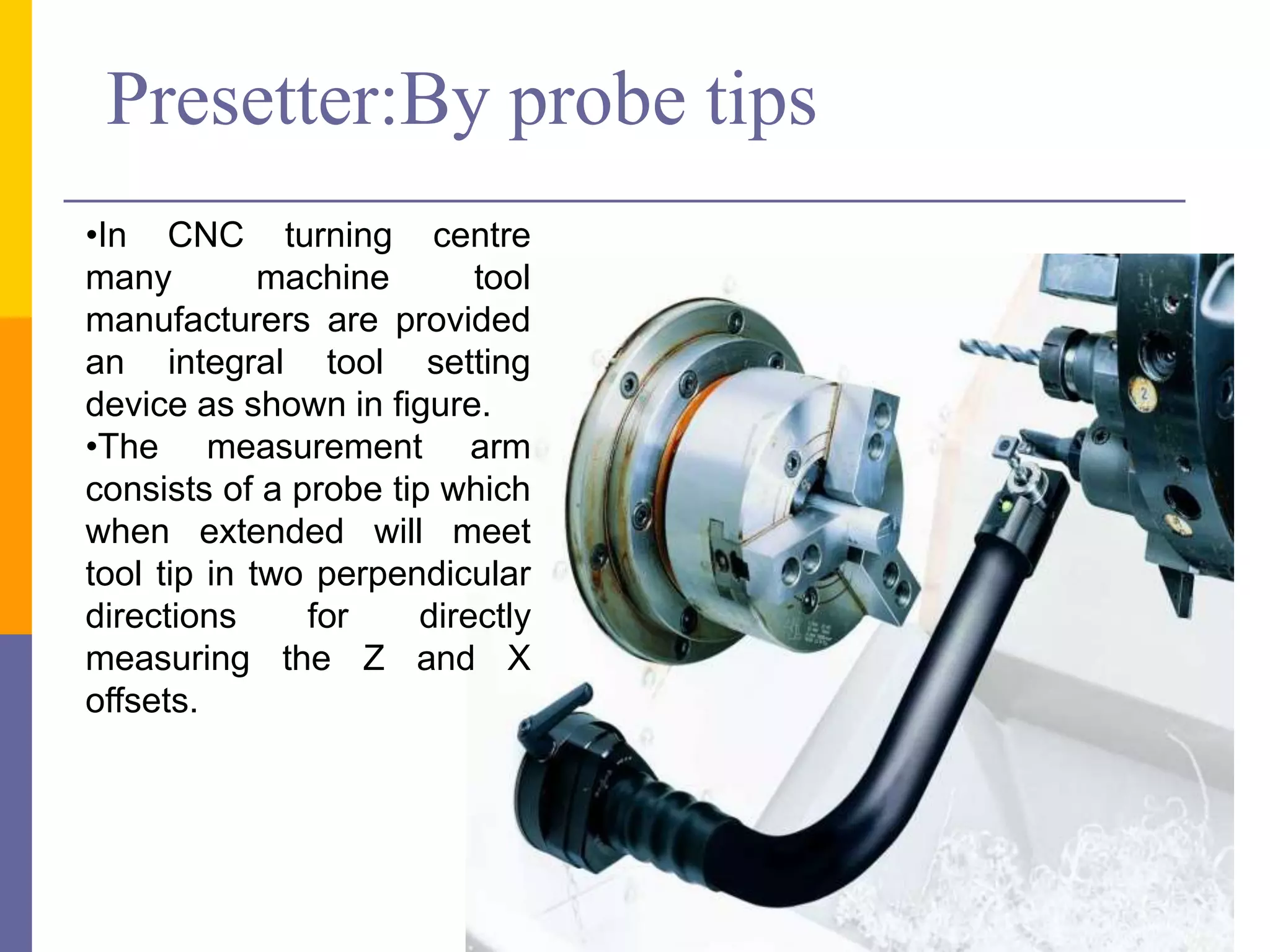

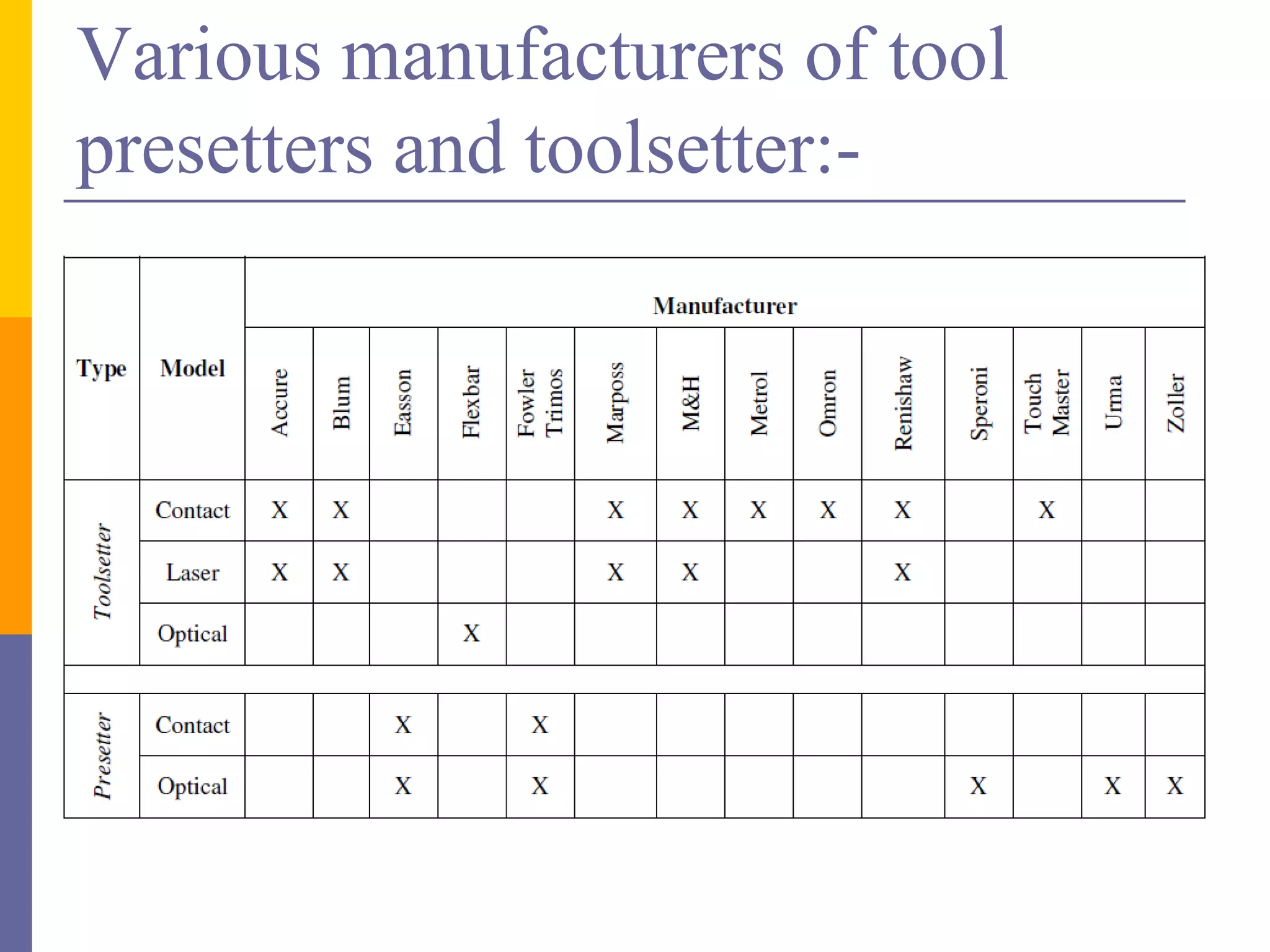

Tool presetting involves measuring tools offline using a presetting device to determine the tool tip location relative to the spindle. This allows setting tools in advance to reduce unproductive time and increase accuracy. There are manual and automatic methods, with automatic being faster and more precise. Presetting devices measure length and diameter to calculate offsets that are input into the CNC to precisely position the tool. While modern CNCs have reduced the need for presetting, it remains important for high-precision or high-volume production to prevent scrapped parts.