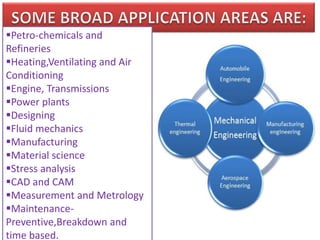

Mechanical engineering deals with the design, production, and operation of machinery. It applies principles of engineering, physics, and materials science.

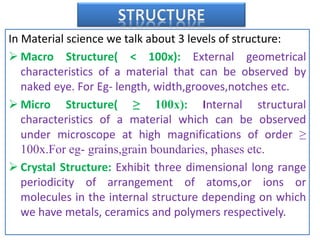

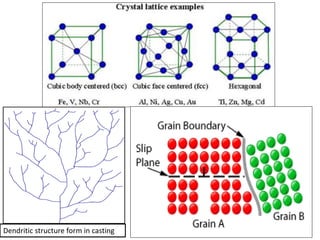

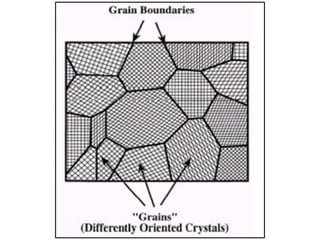

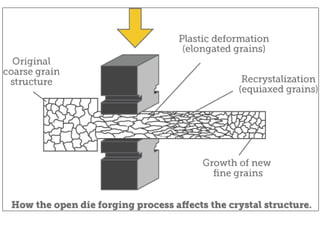

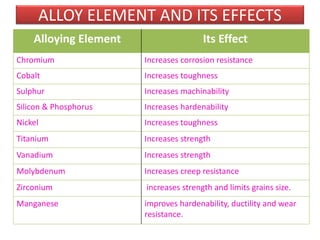

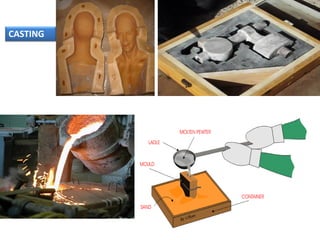

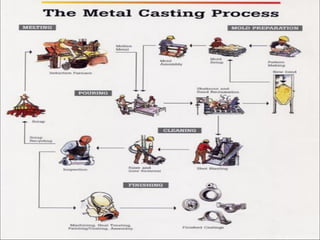

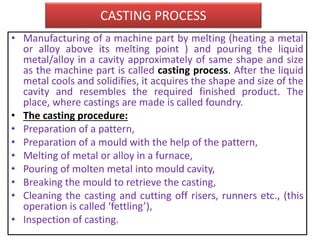

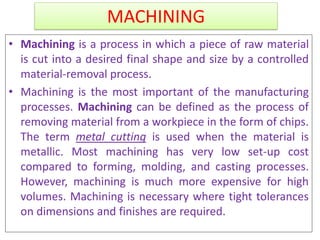

Material science studies the relationship between the structure and properties of materials. The structure of materials depends on manufacturing processes like casting and machining.

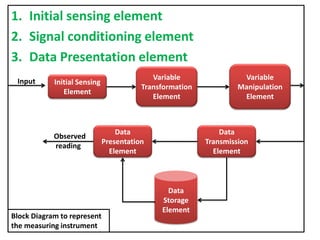

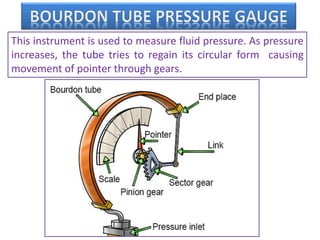

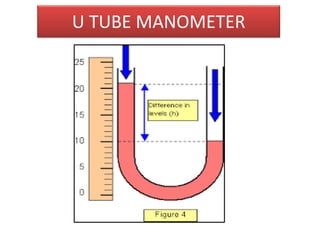

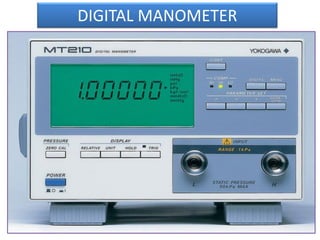

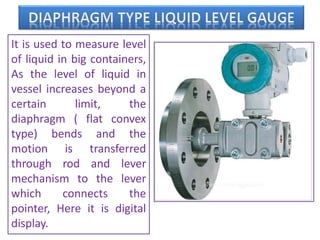

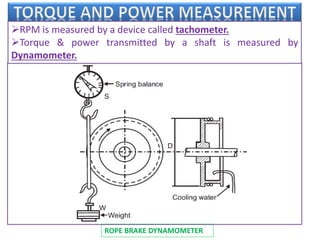

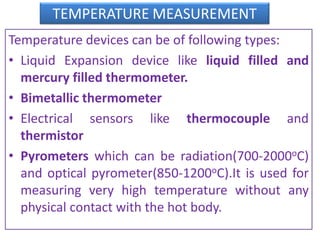

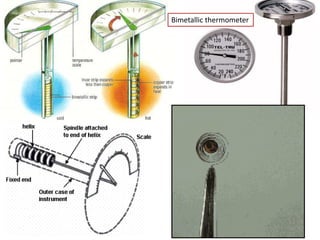

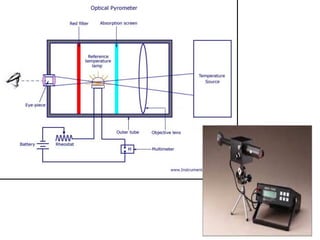

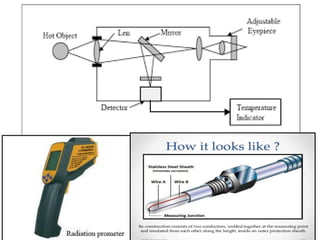

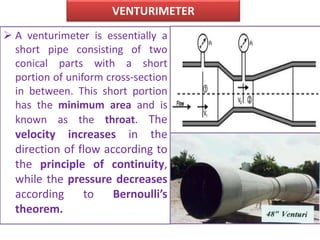

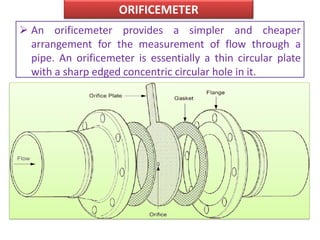

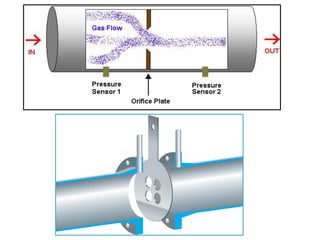

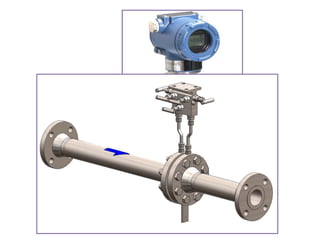

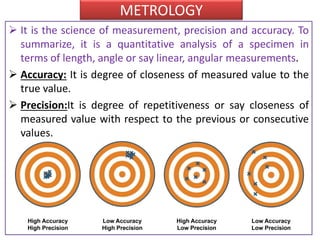

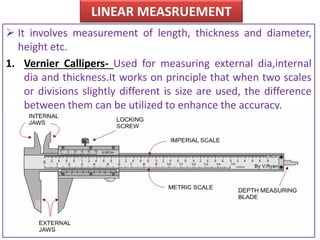

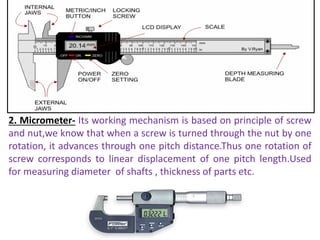

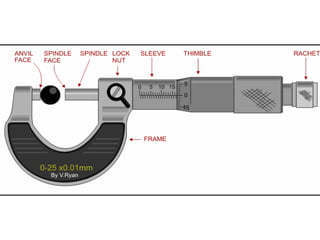

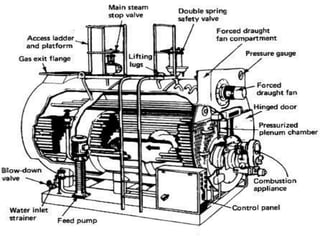

Measurement and metrology involve measuring devices that determine parameters like pressure, temperature, and flow rate. Measuring instruments have sensing, conditioning, and presentation elements. Common instruments include pressure gauges, thermometers, tachometers, and dynamometers.