This document provides information about Numerical Control (NC) and Computer Numerical Control (CNC) machines. It discusses:

- The difference between NC and CNC machines, with CNC machines having more advanced computer control capabilities than early NC machines controlled by tape or cards.

- The history and evolution of CNC, starting from early NC machines developed in the 1940s-1950s controlled by punch cards and tape, to the introduction of microprocessors and computers enabling more advanced CNC machines from the 1970s onward.

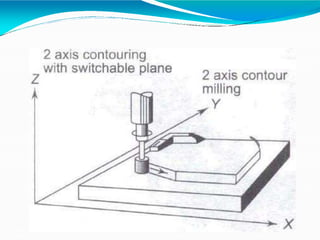

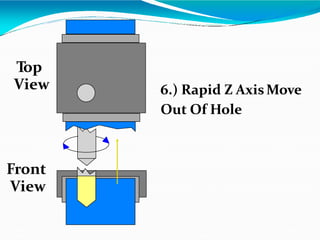

- Key enhancements provided by CNC over NC include canned cycles, sub-programming, compensation functions, and more complex interpolation capabilities like B-splines.

- CNC

![IES 2011 Conventional

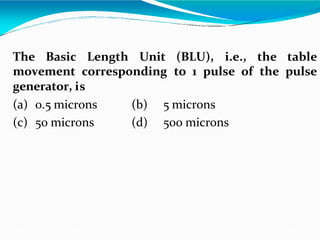

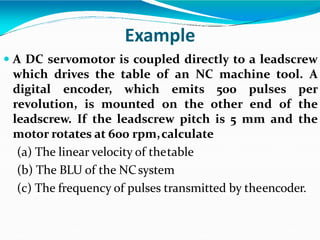

The table of a CNC machine is driven by a Lead screw which

is rotated by a DC servomotor. A digital encoder which emits

1000 pulses per second is mounted on the lead screw as a

feedback device. If the lead screw pitch is 6 mm and motor

rotates at 500 rpm,find

1. Basic length Units of thesystem

2. Linear velocity of thetable.

3. Frequency of pulses generated by the feedbackdevice.

[5 Marks]](https://image.slidesharecdn.com/ch-11nccncdncfmsautomationandrobotics-170819193642/85/nc-and-cnc-dp-24-320.jpg)