The document discusses CNC part programming and provides information on:

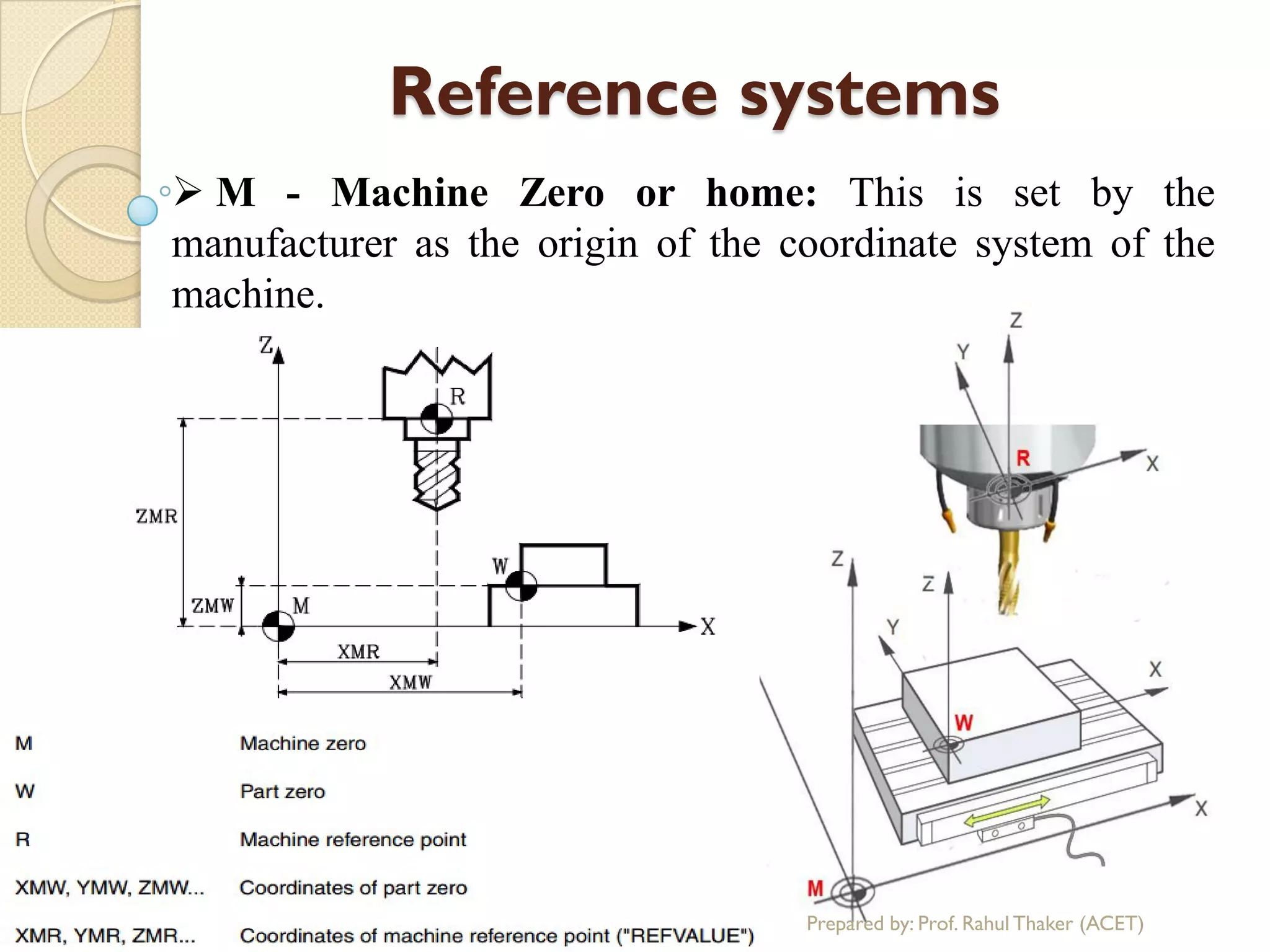

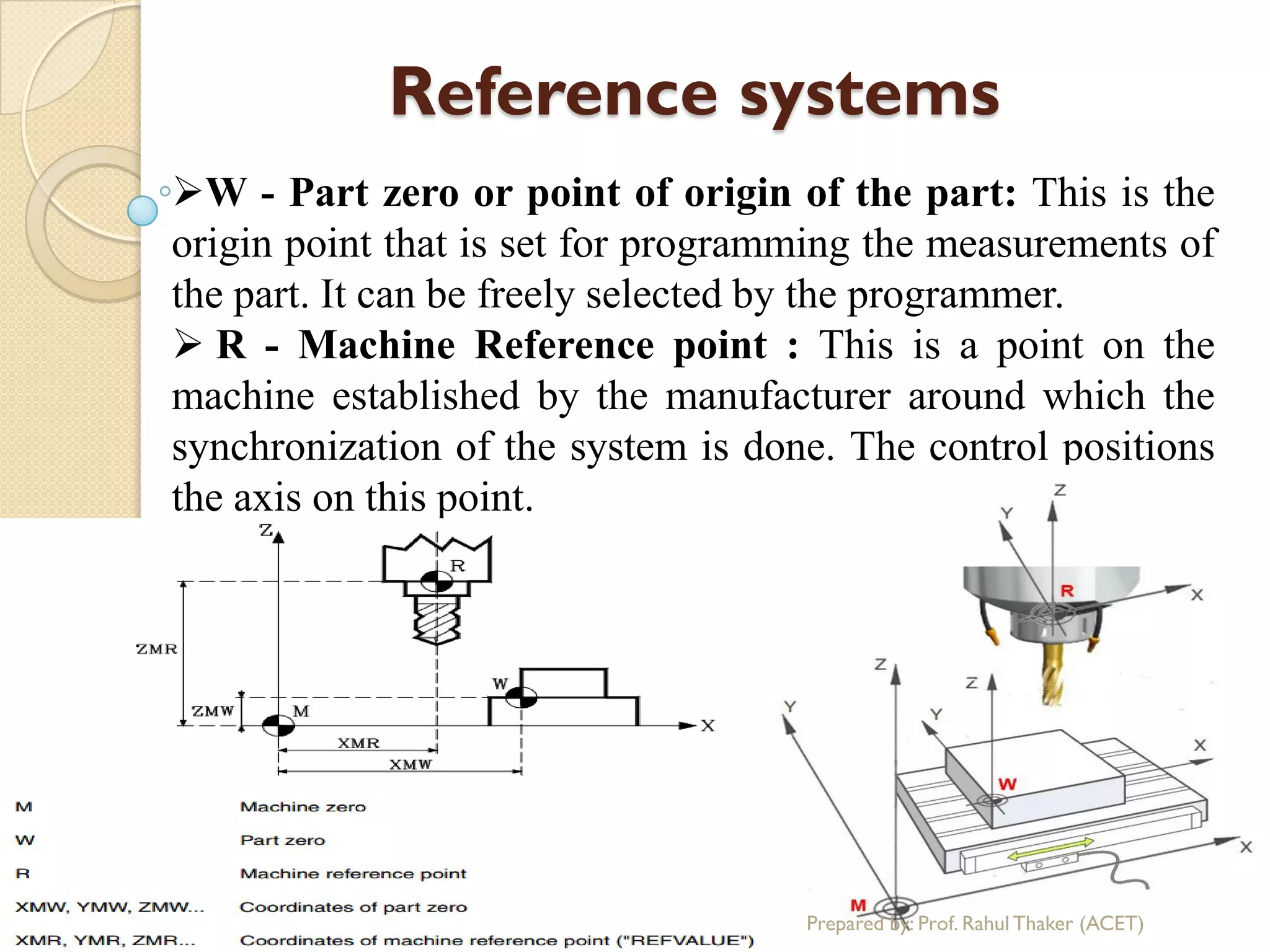

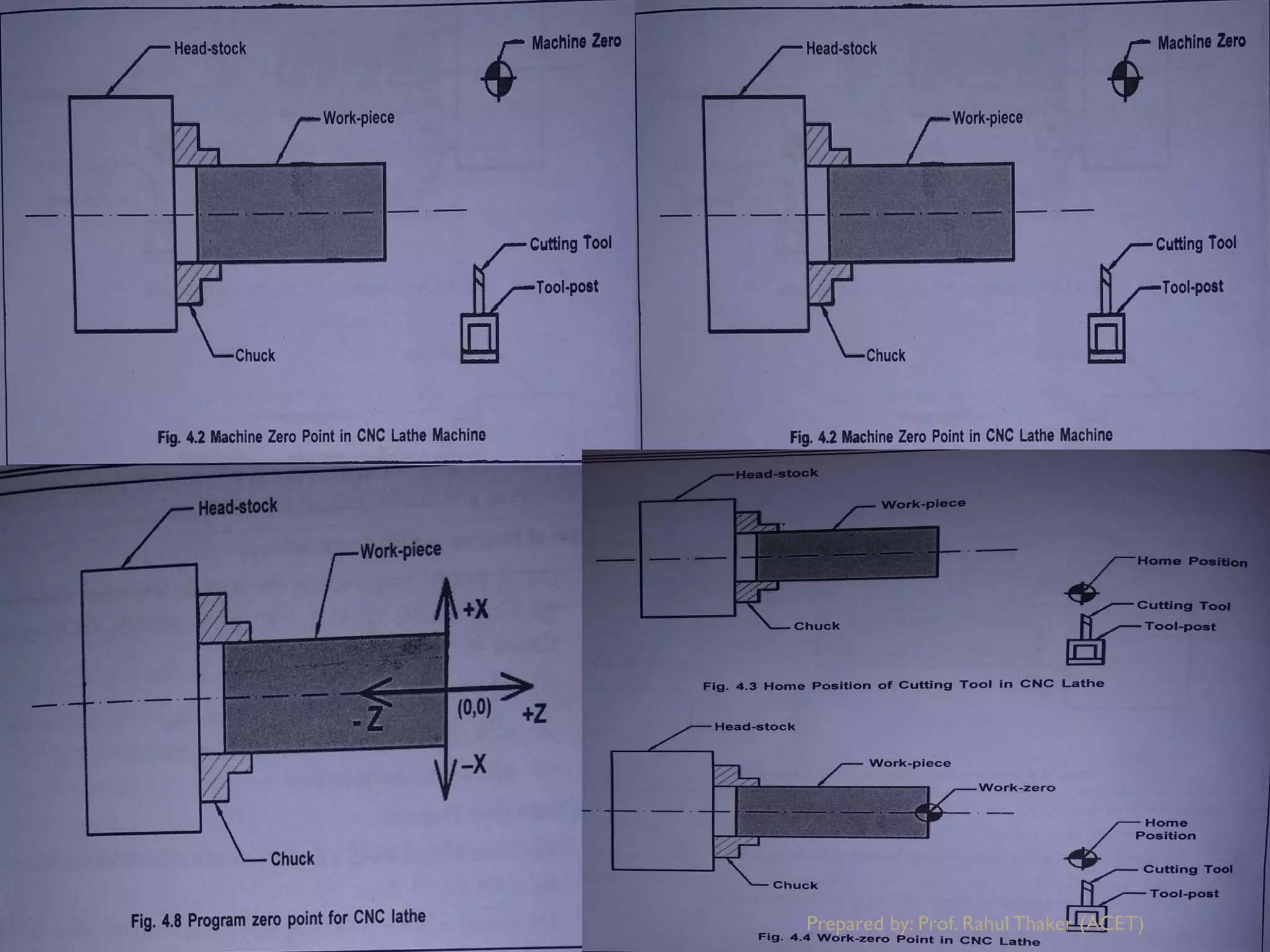

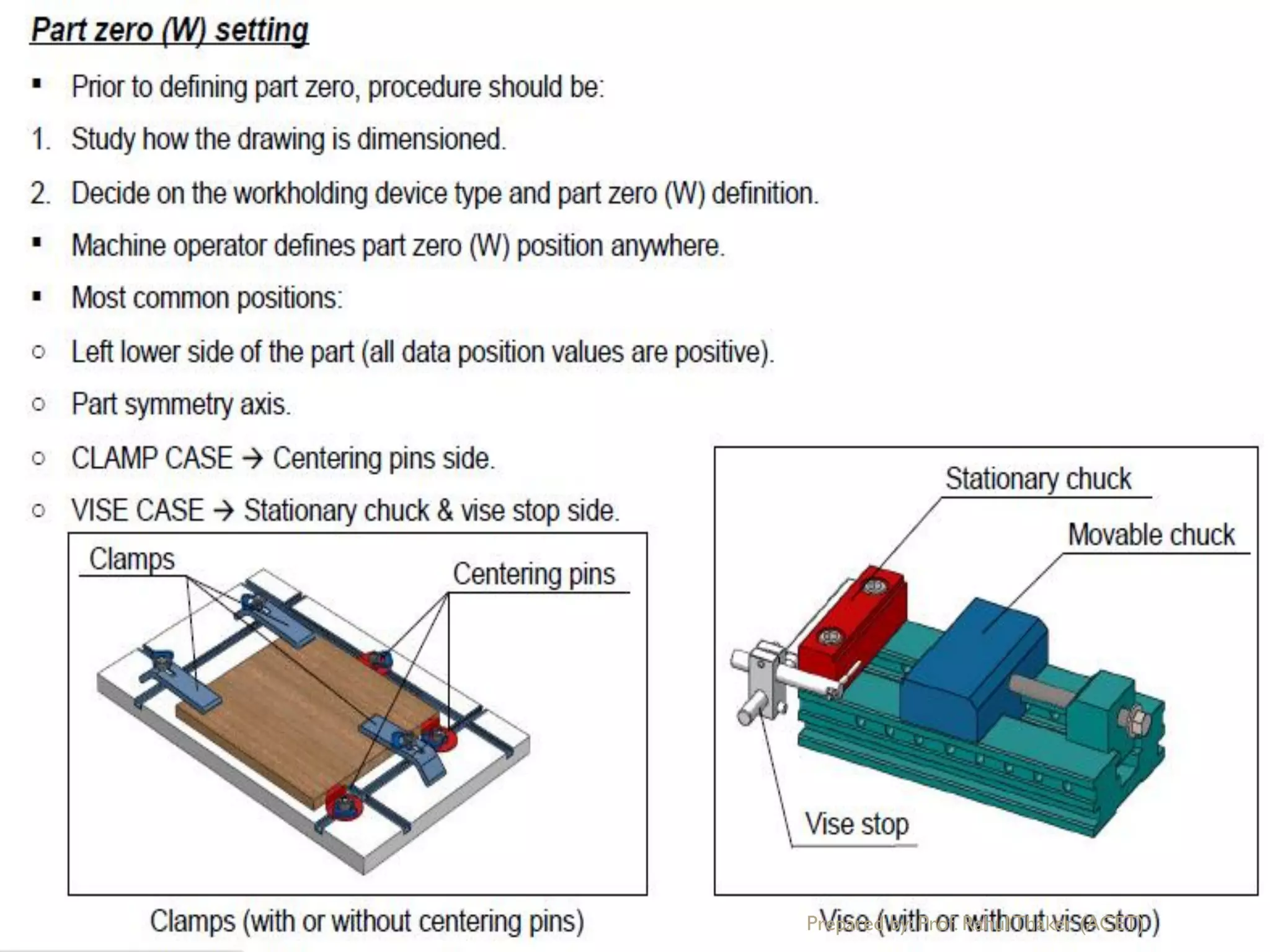

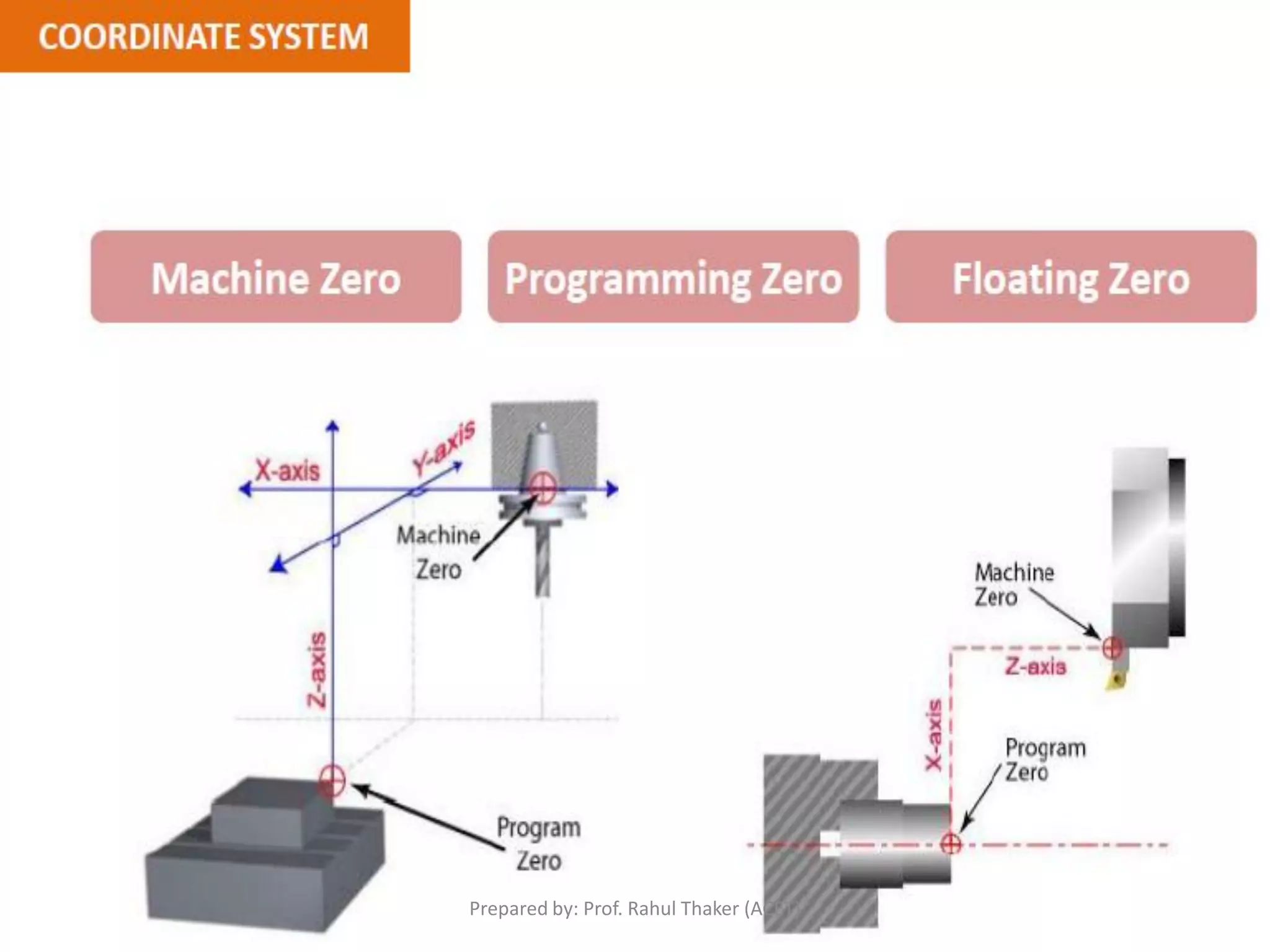

- Reference systems used in CNC programming including machine zero, part zero, and machine reference point.

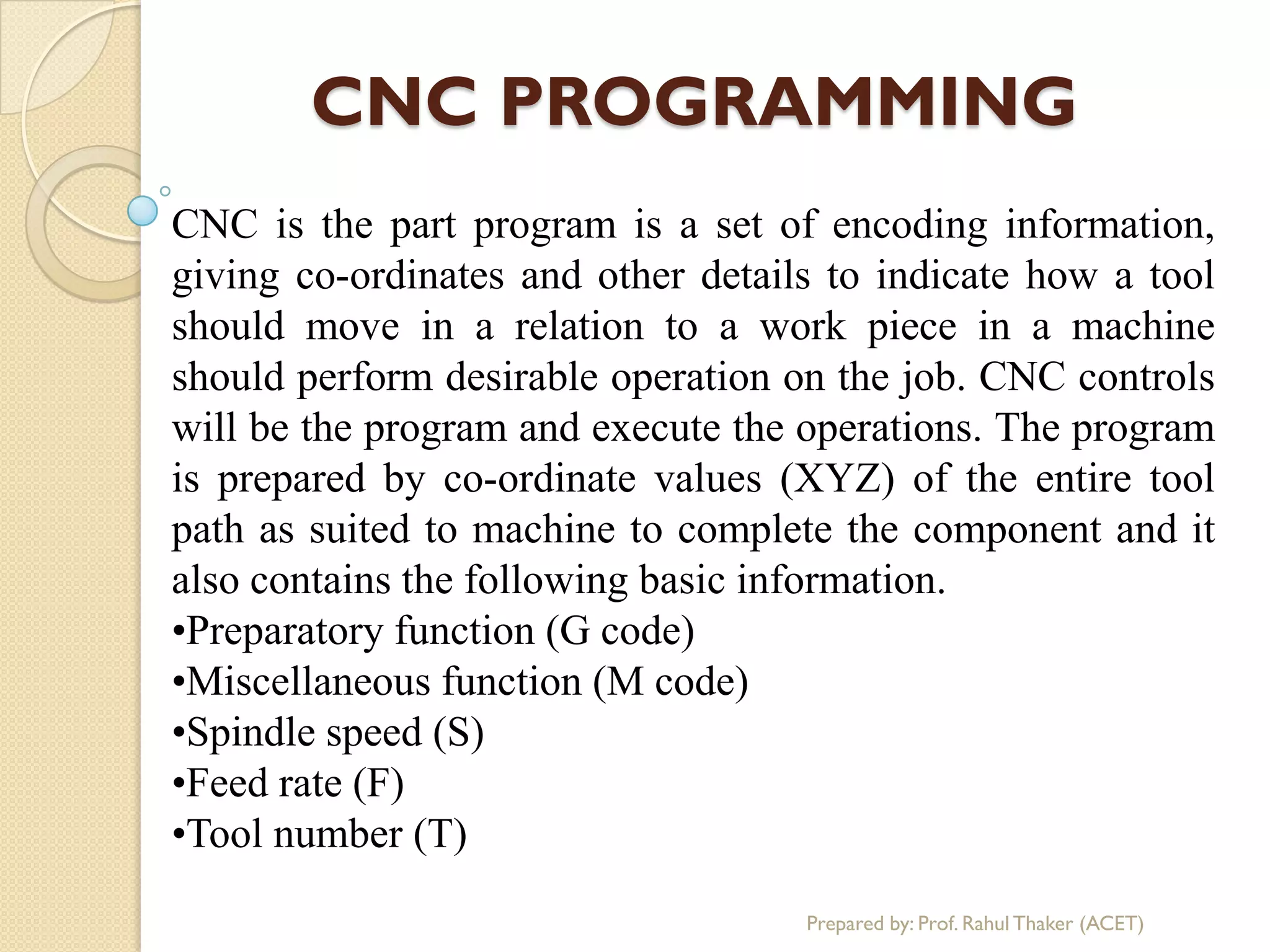

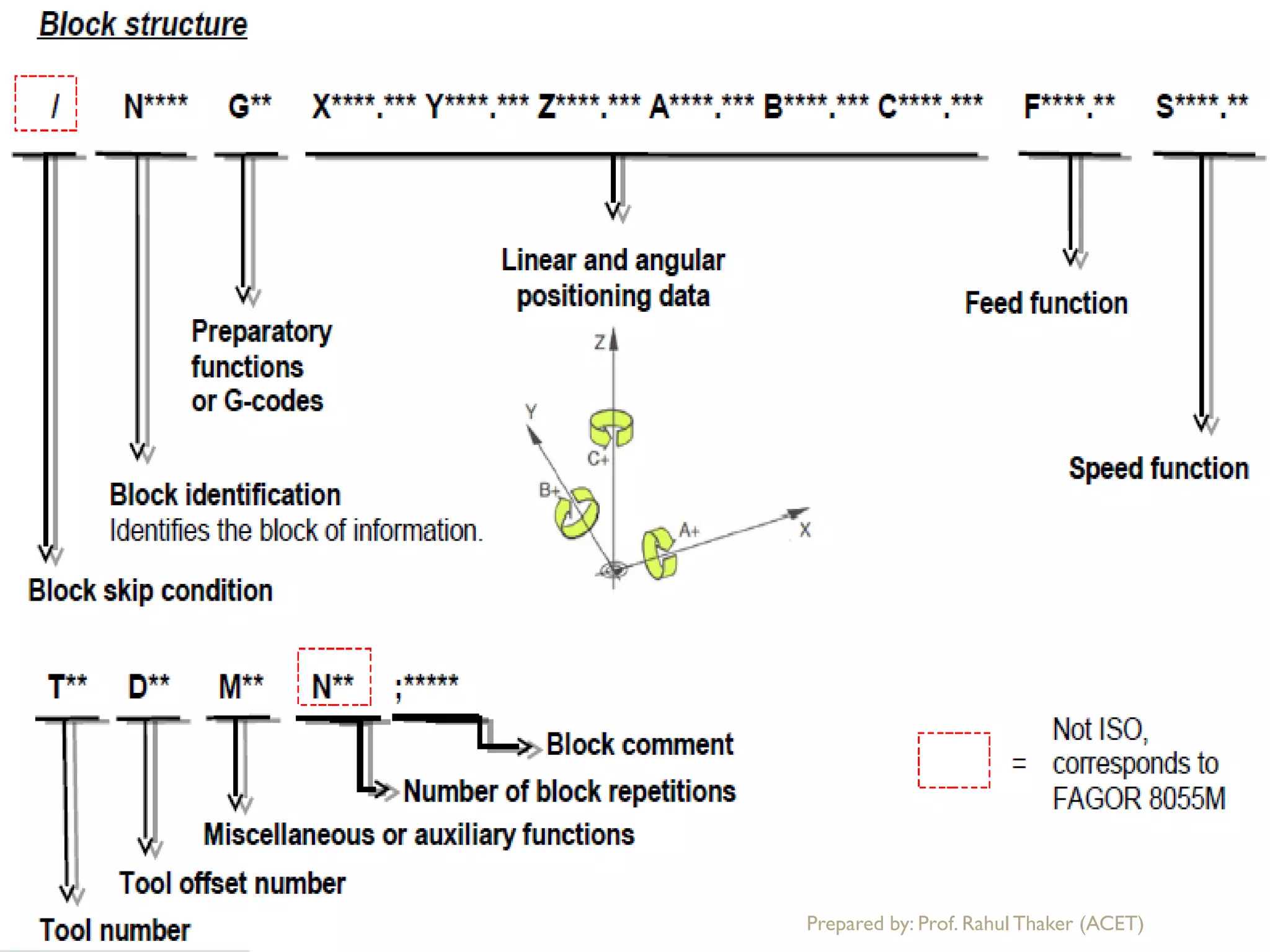

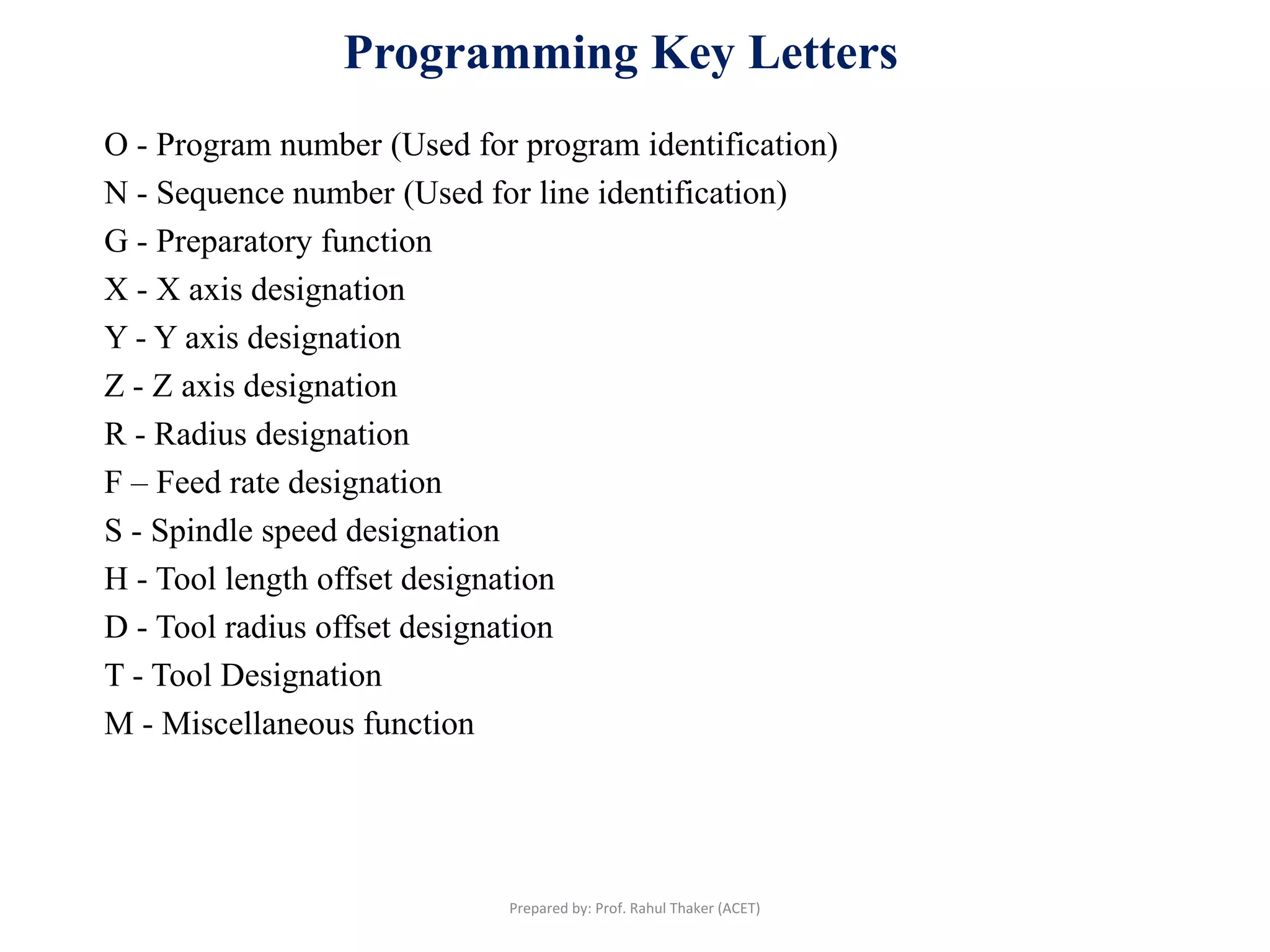

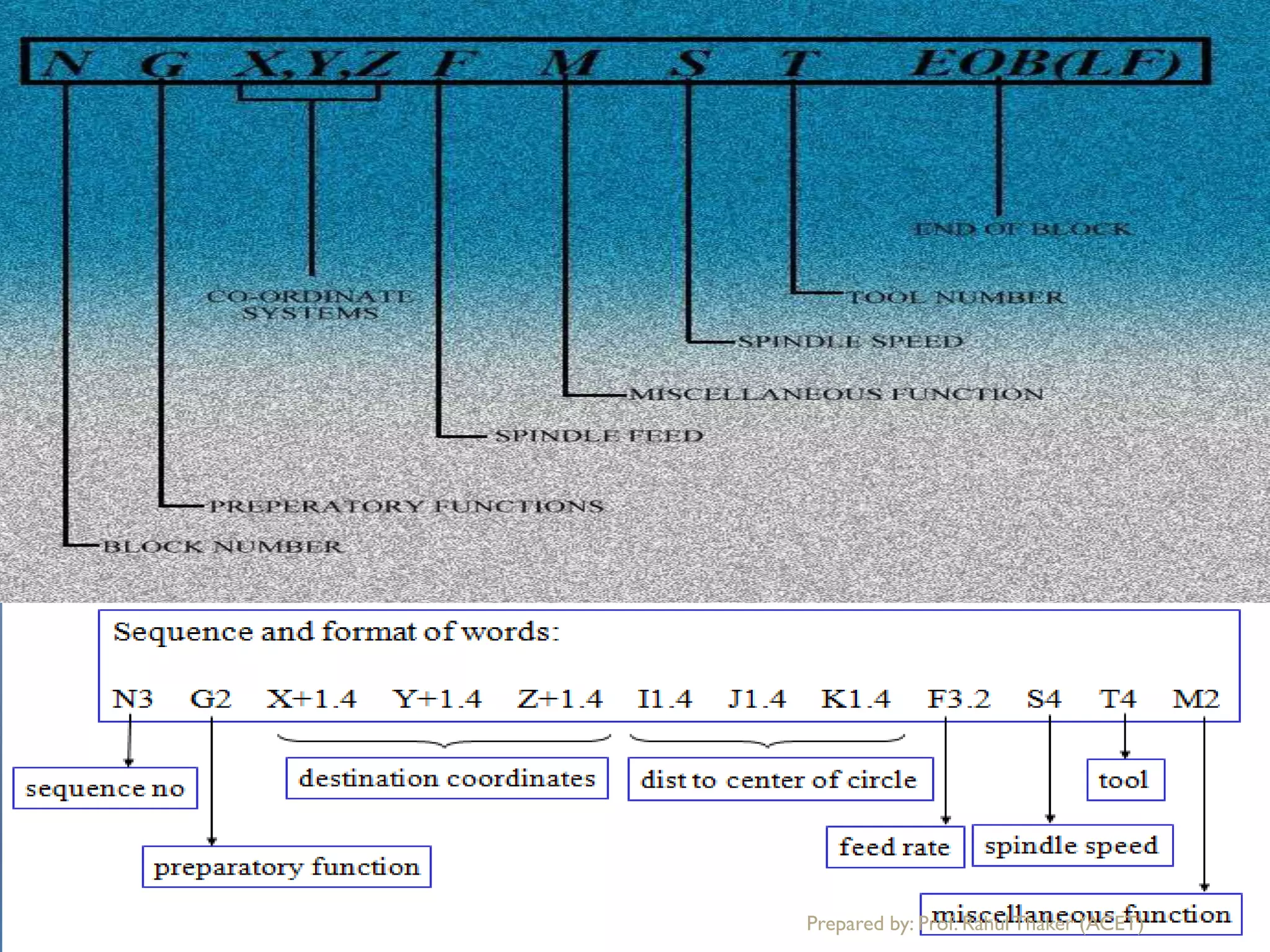

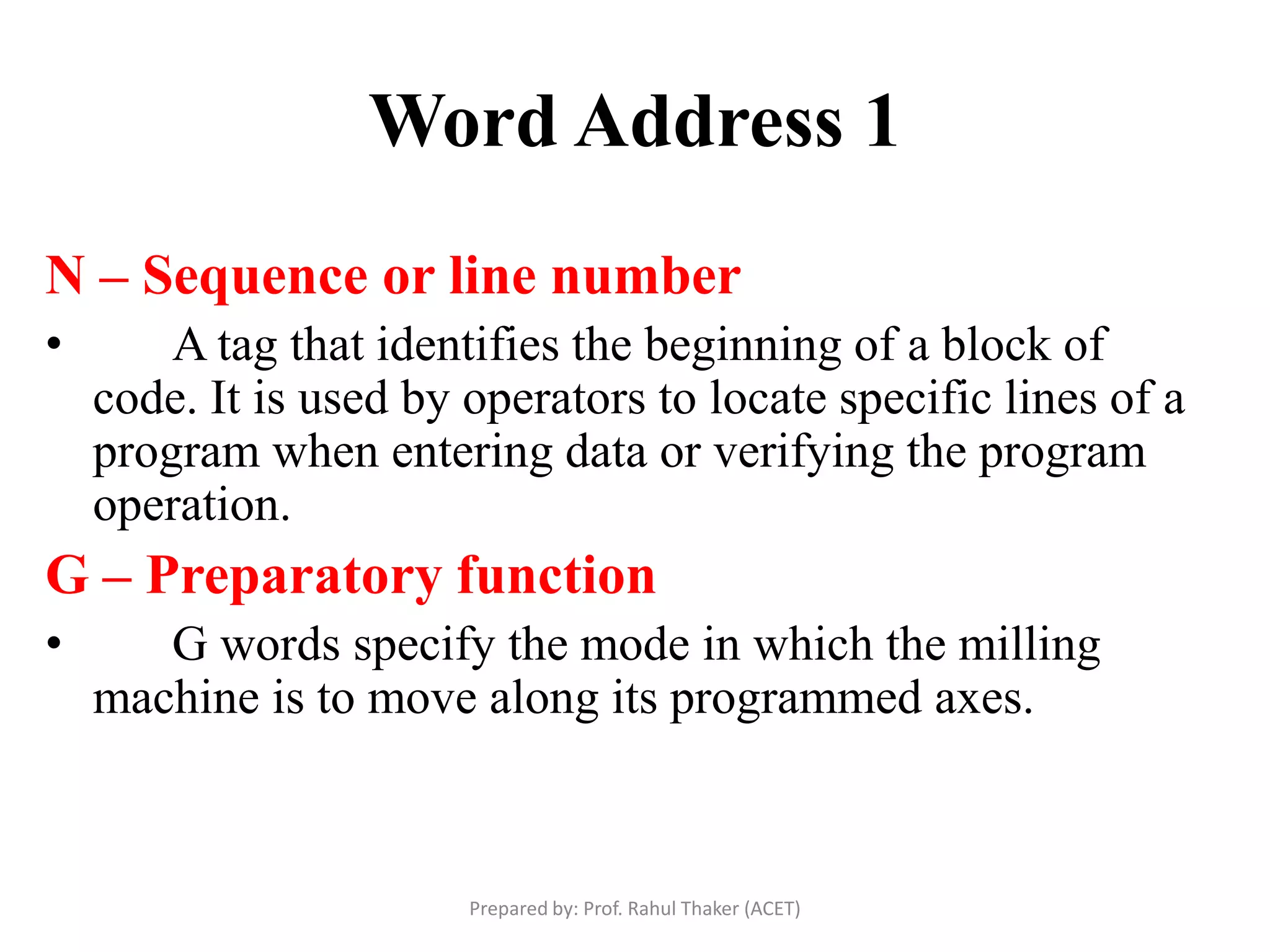

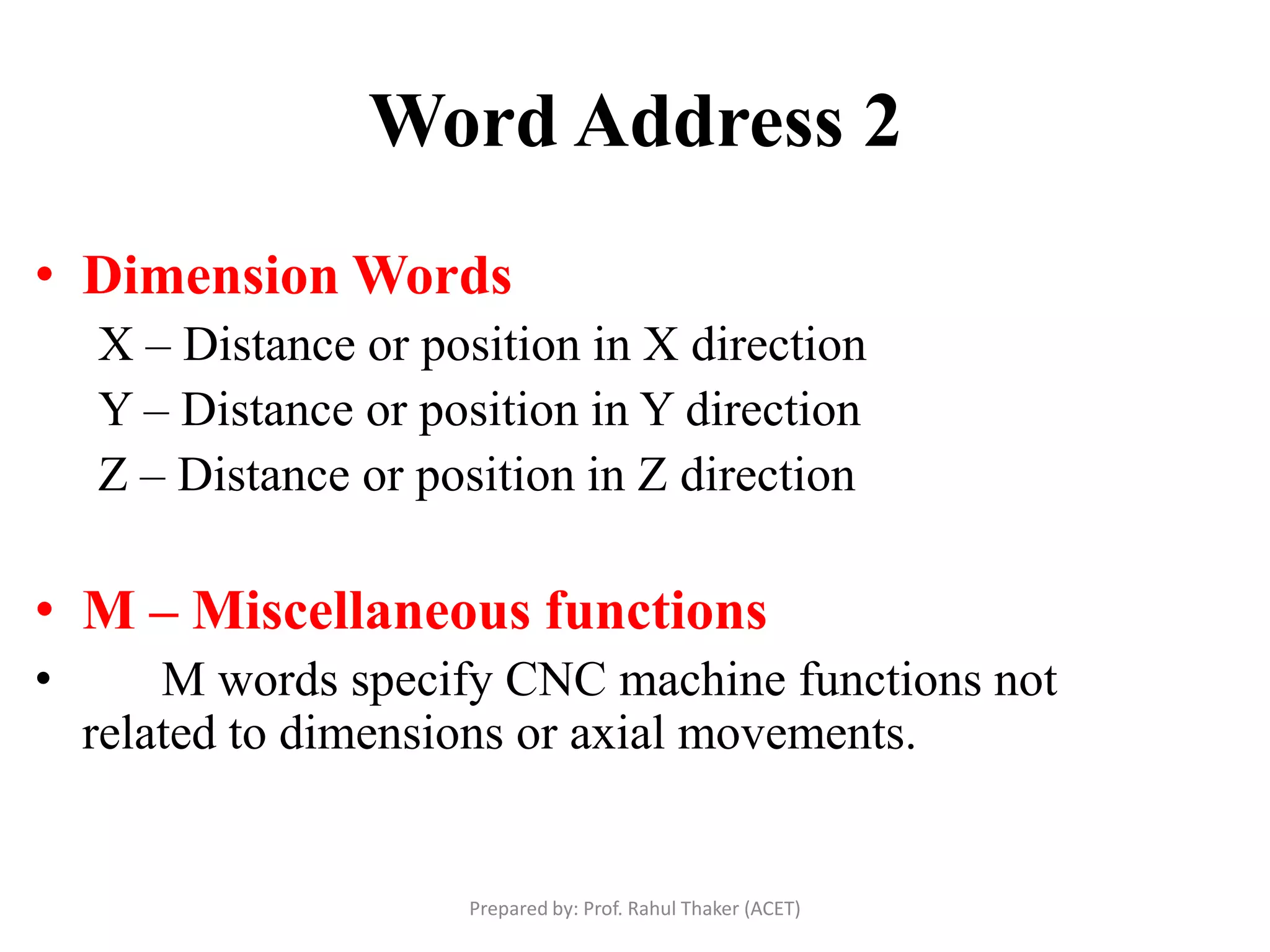

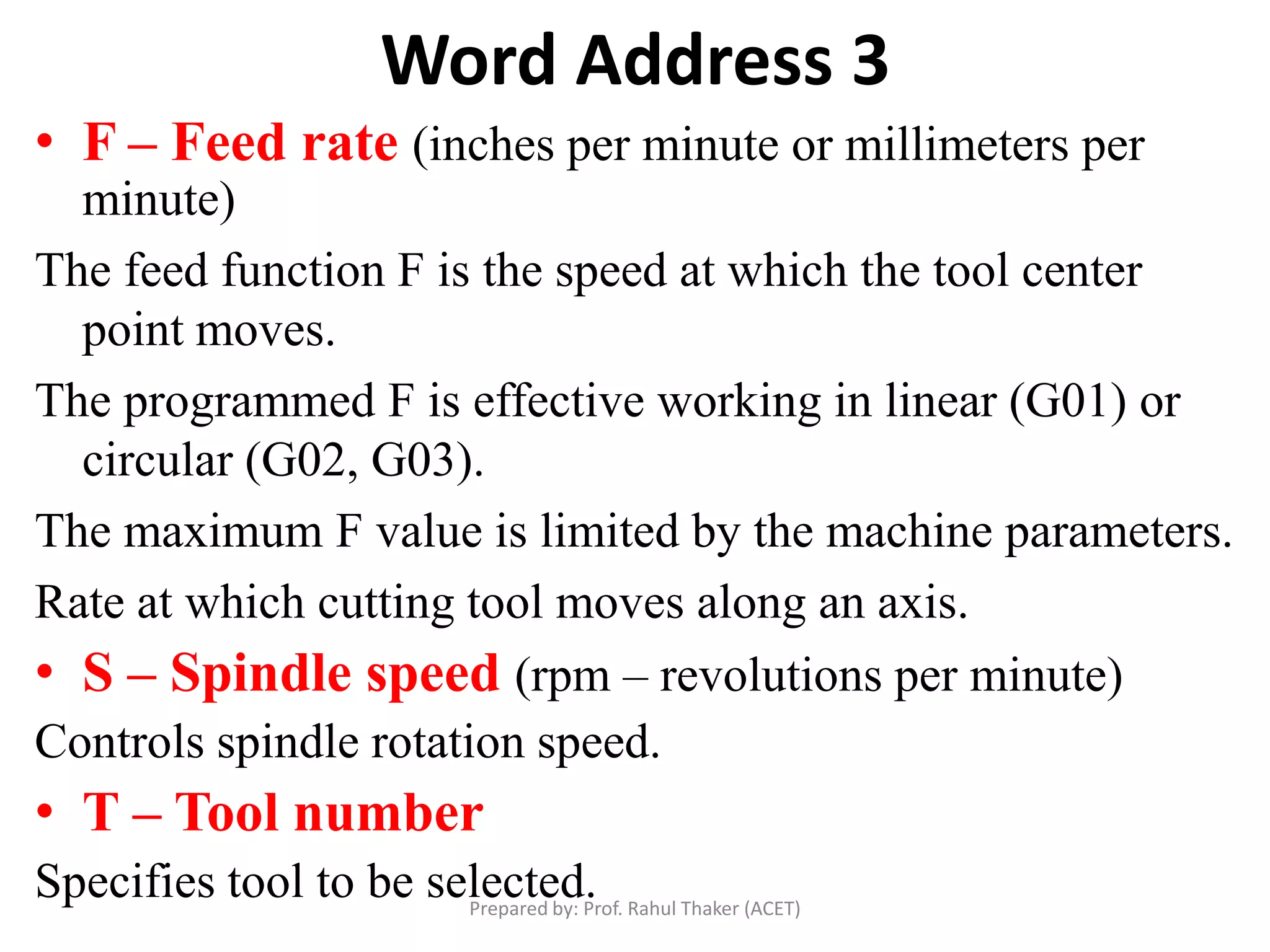

- Key elements that make up a CNC program including preparatory functions, dimensions, feed rates, spindle speeds, and tool information.

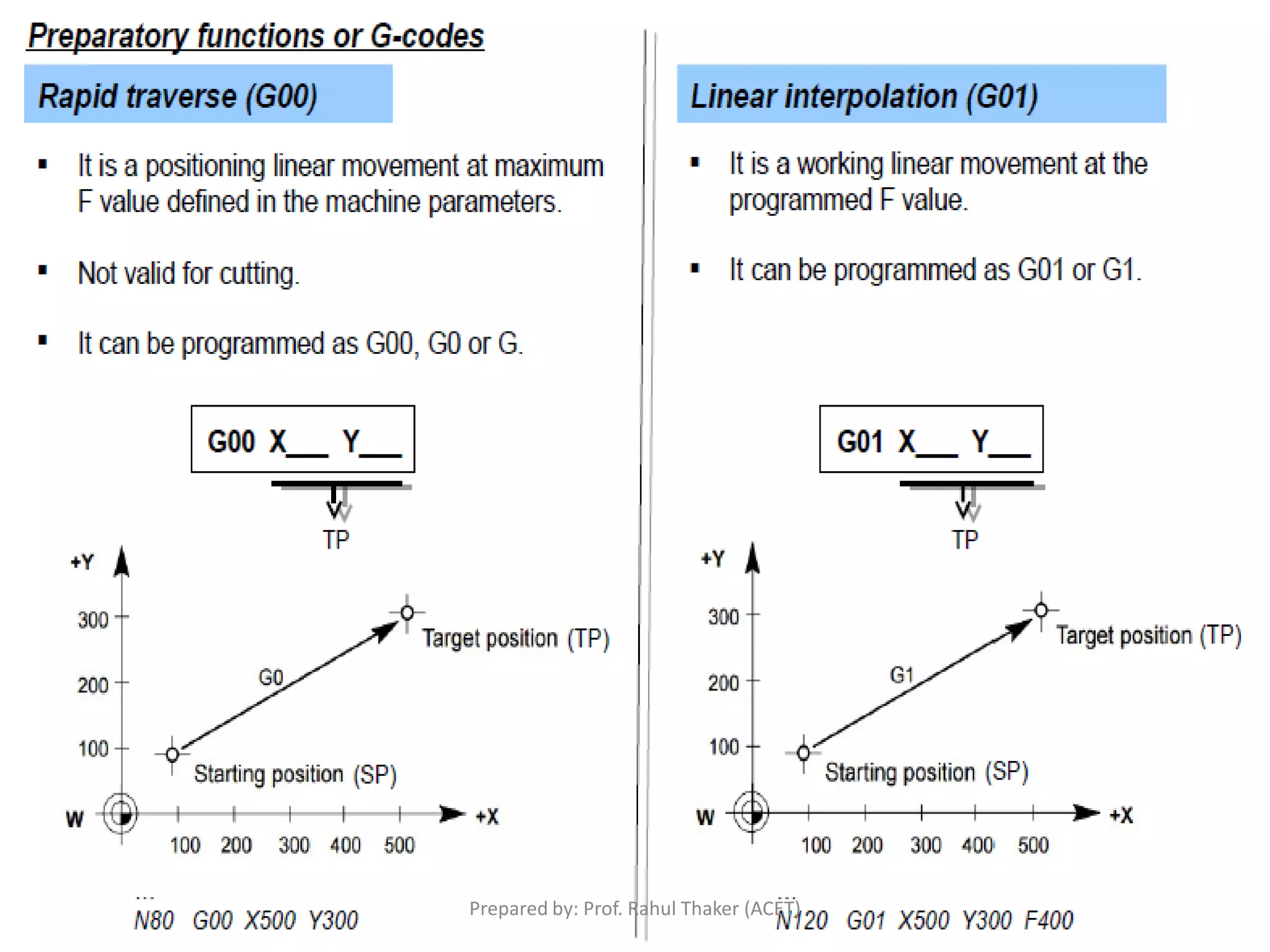

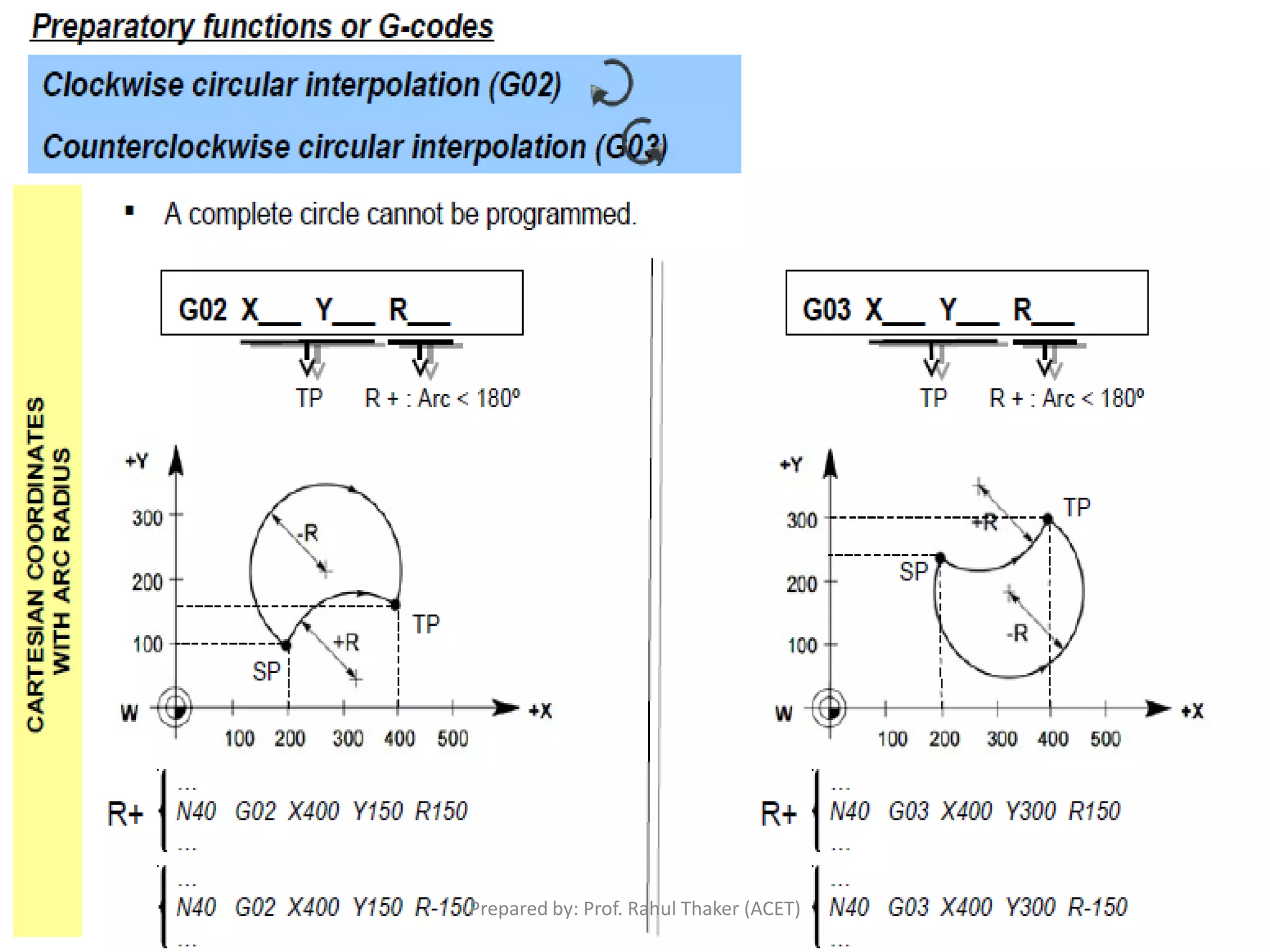

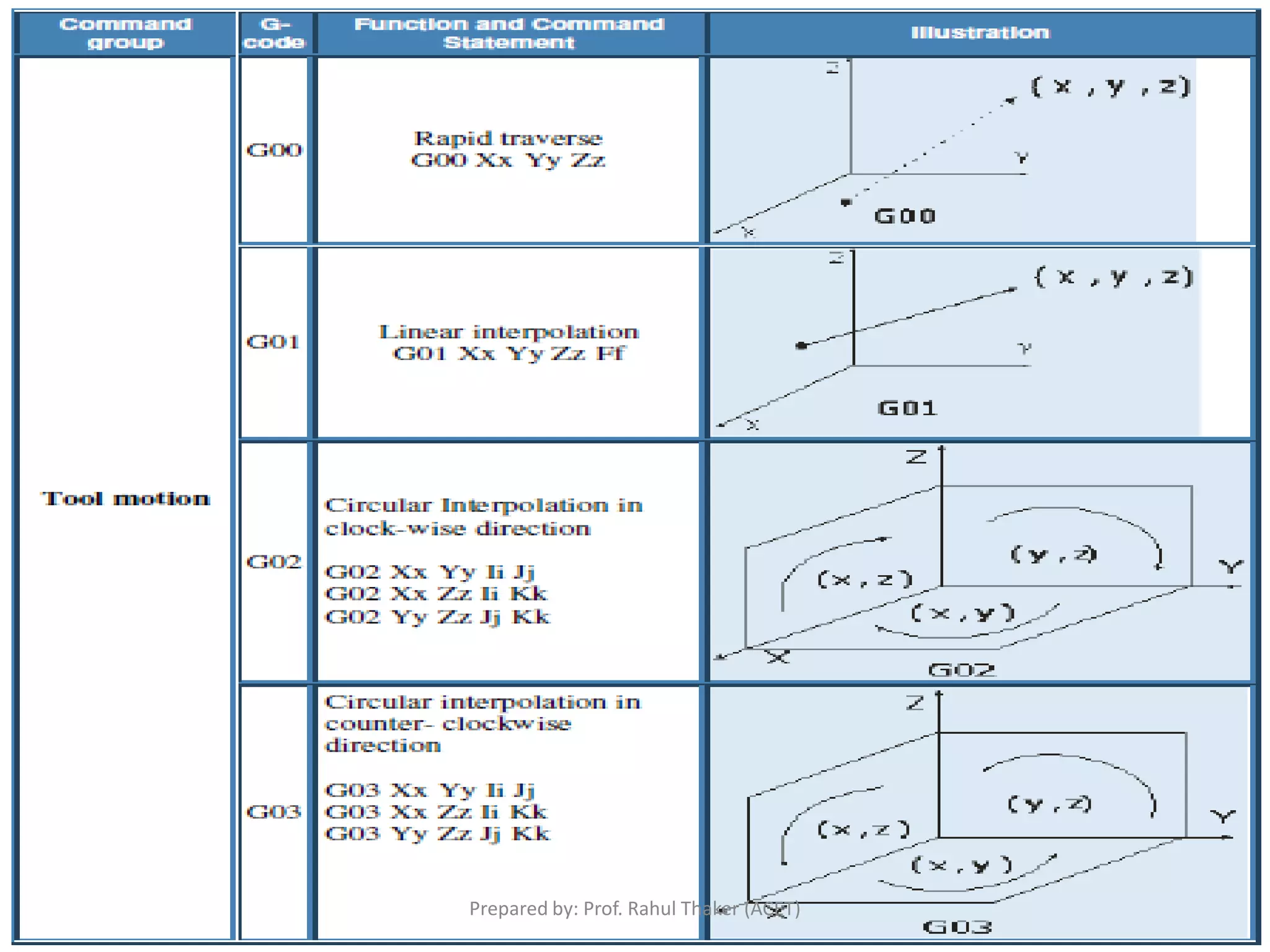

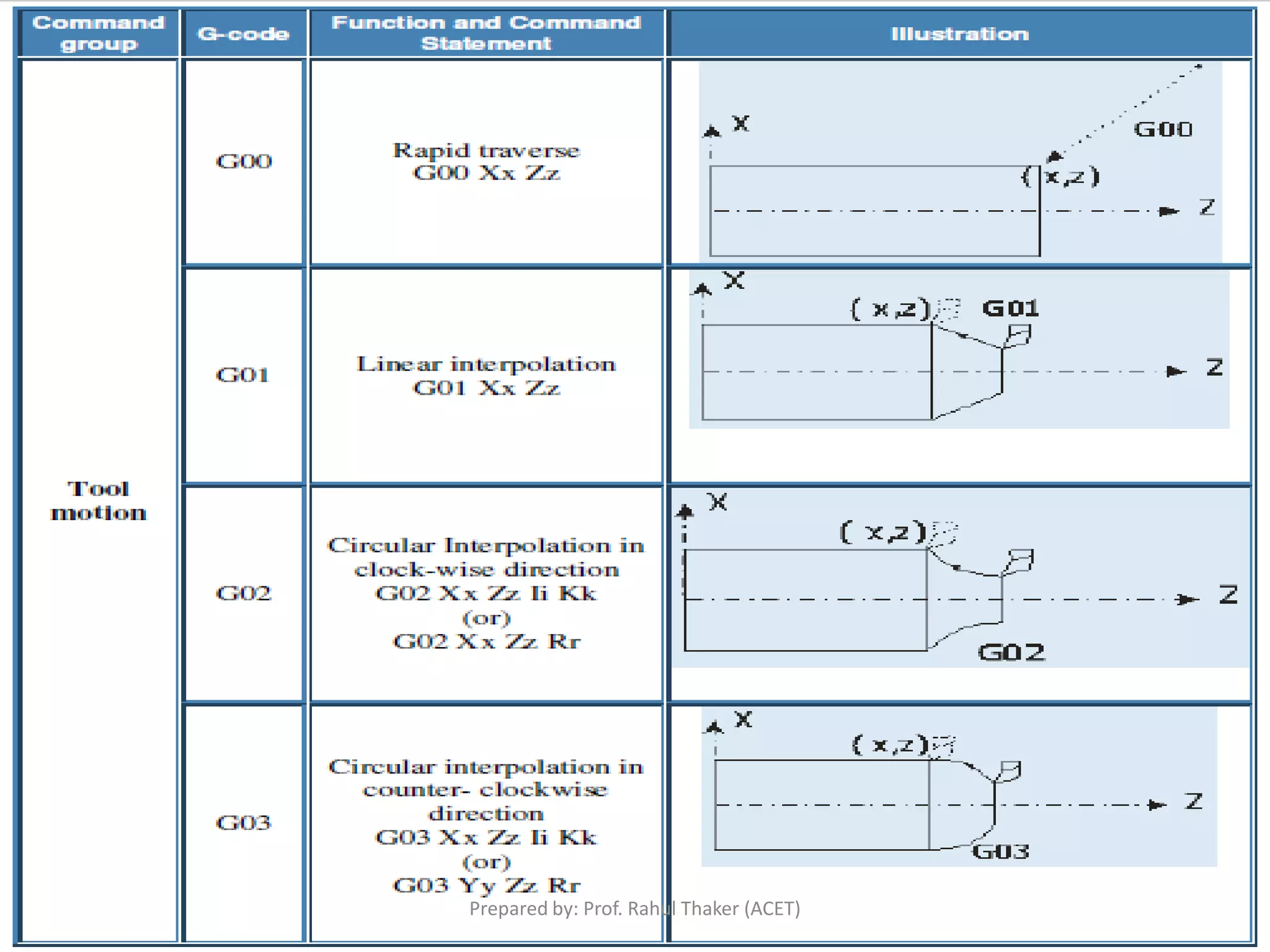

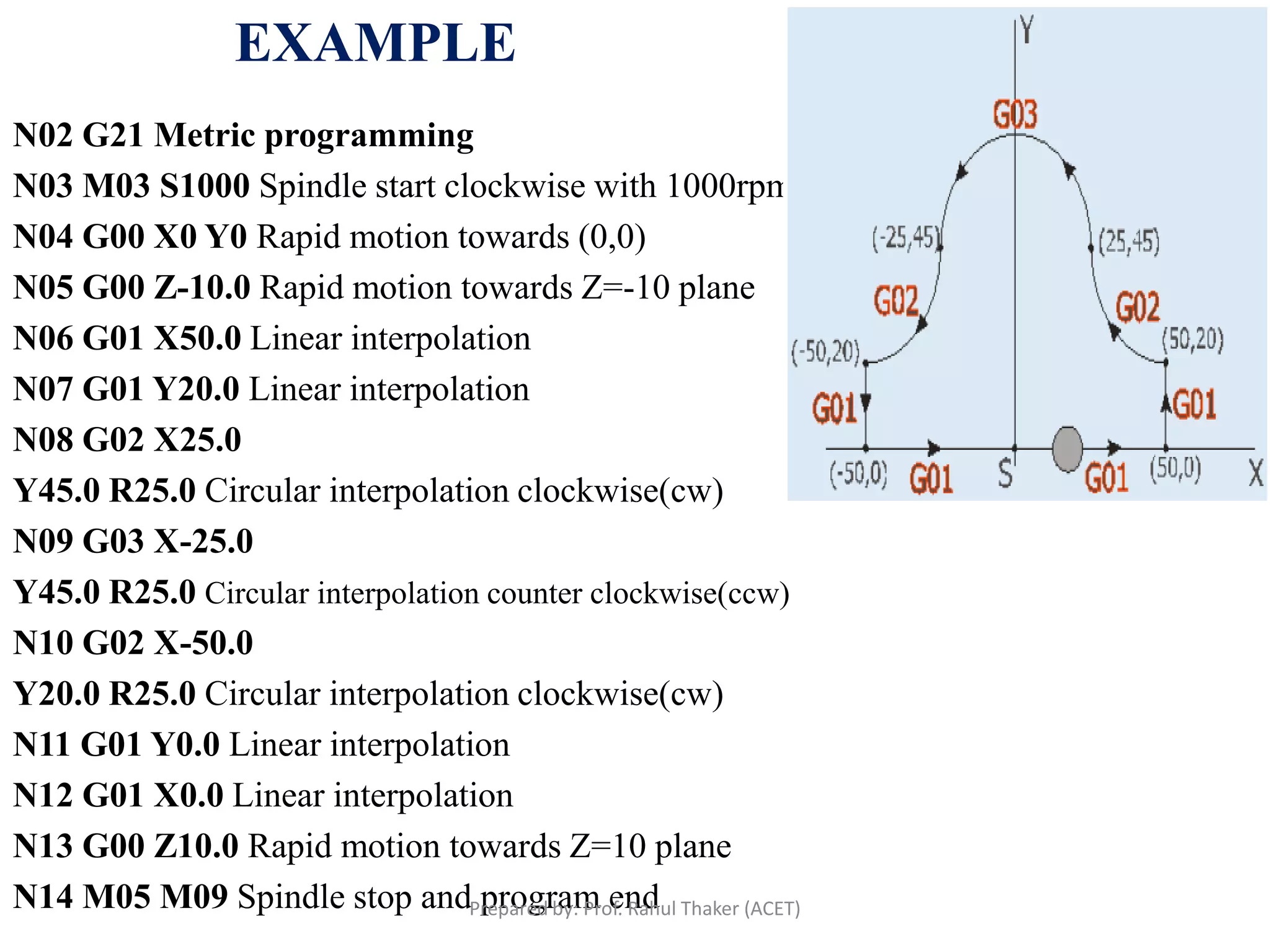

- Common G-codes (preparatory functions) and M-codes (miscellaneous functions) used in programming.

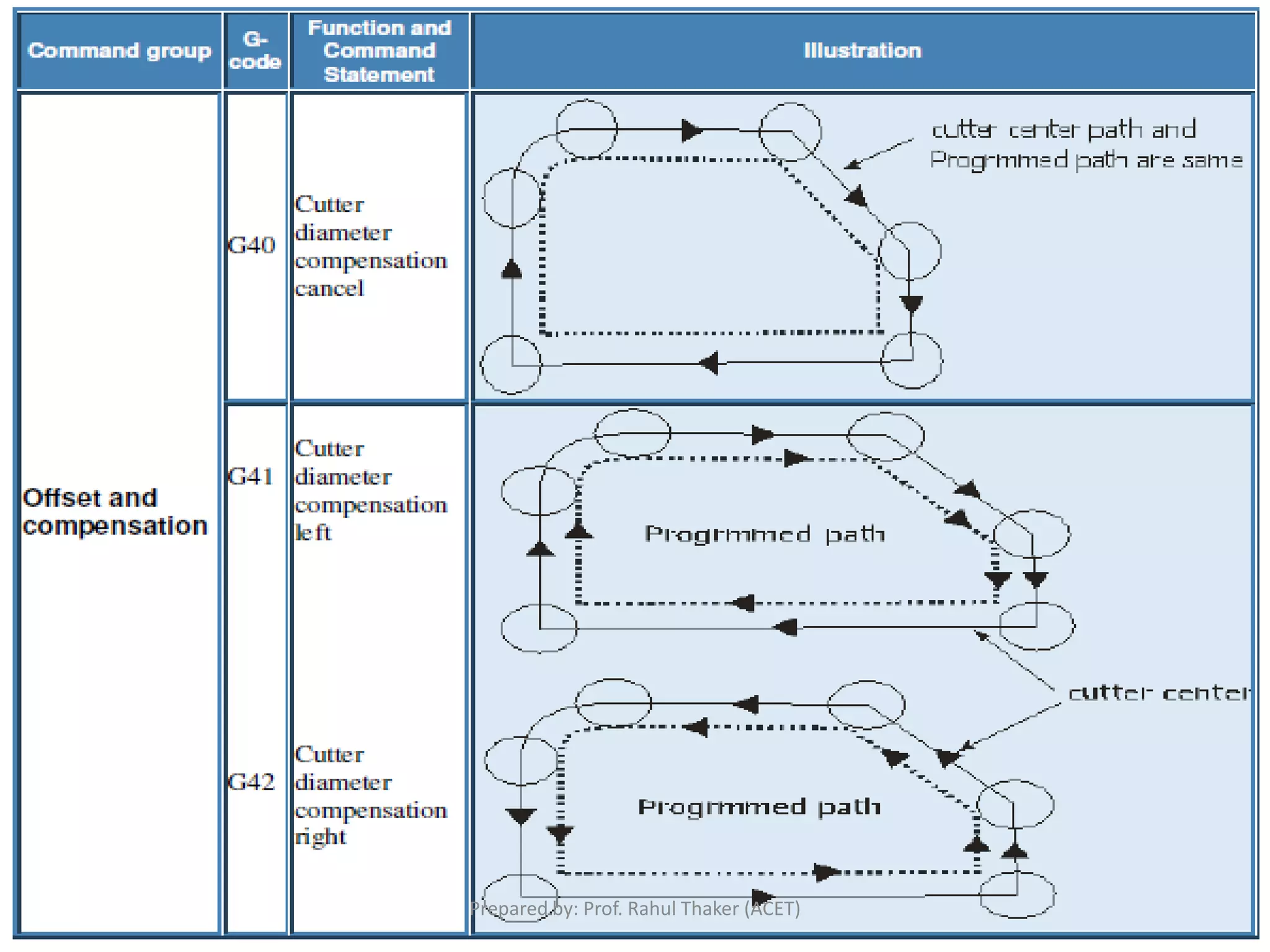

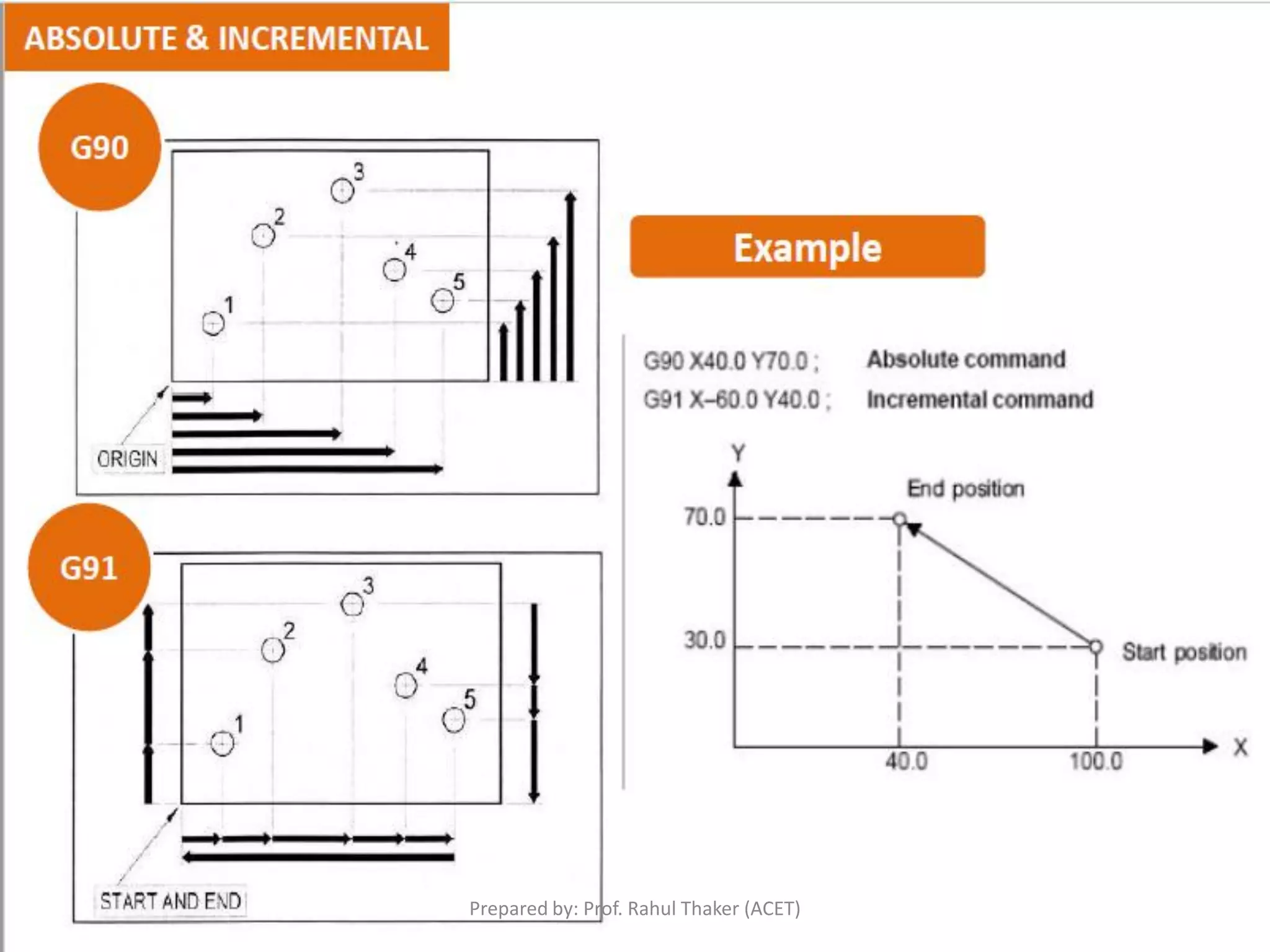

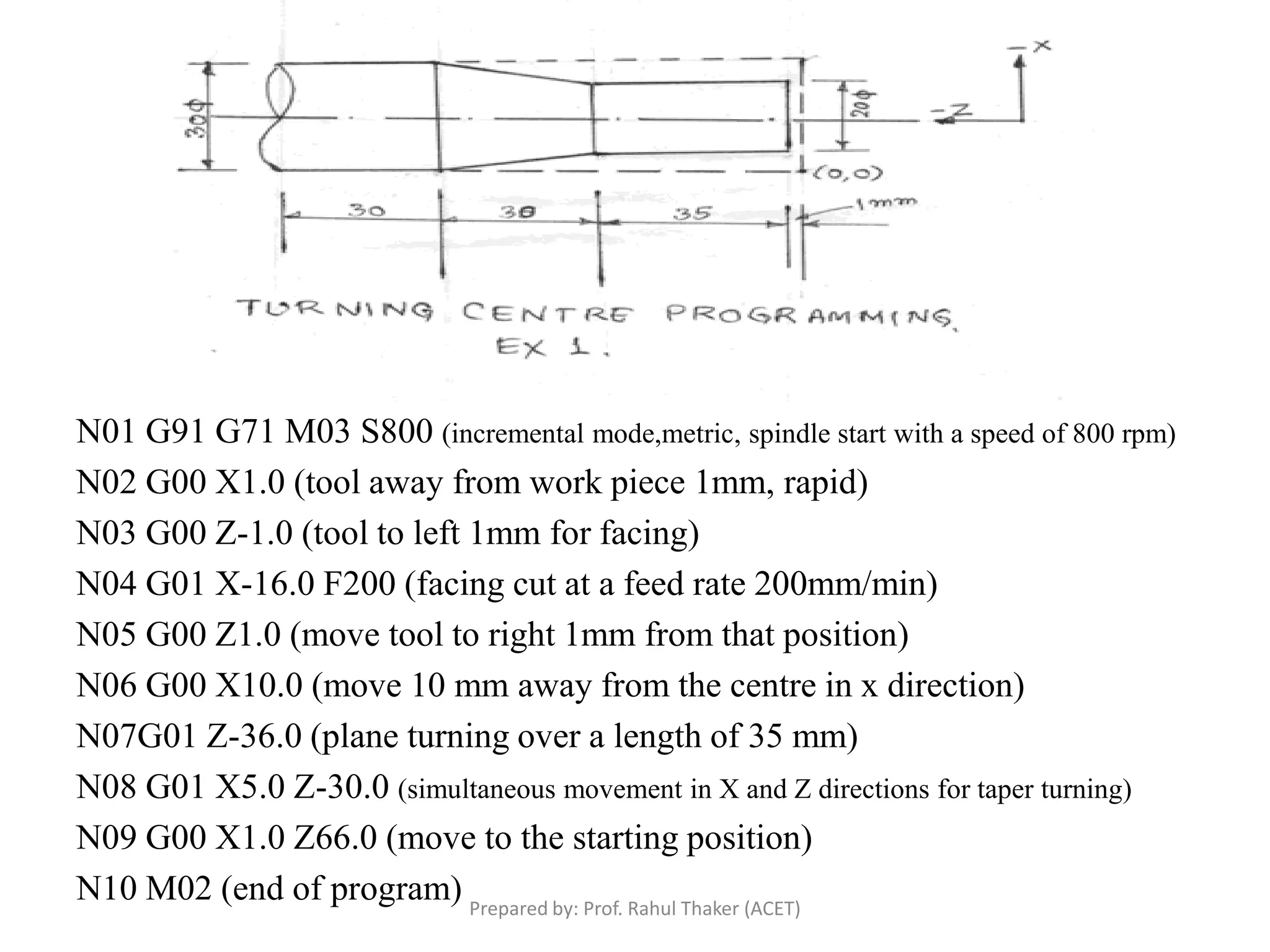

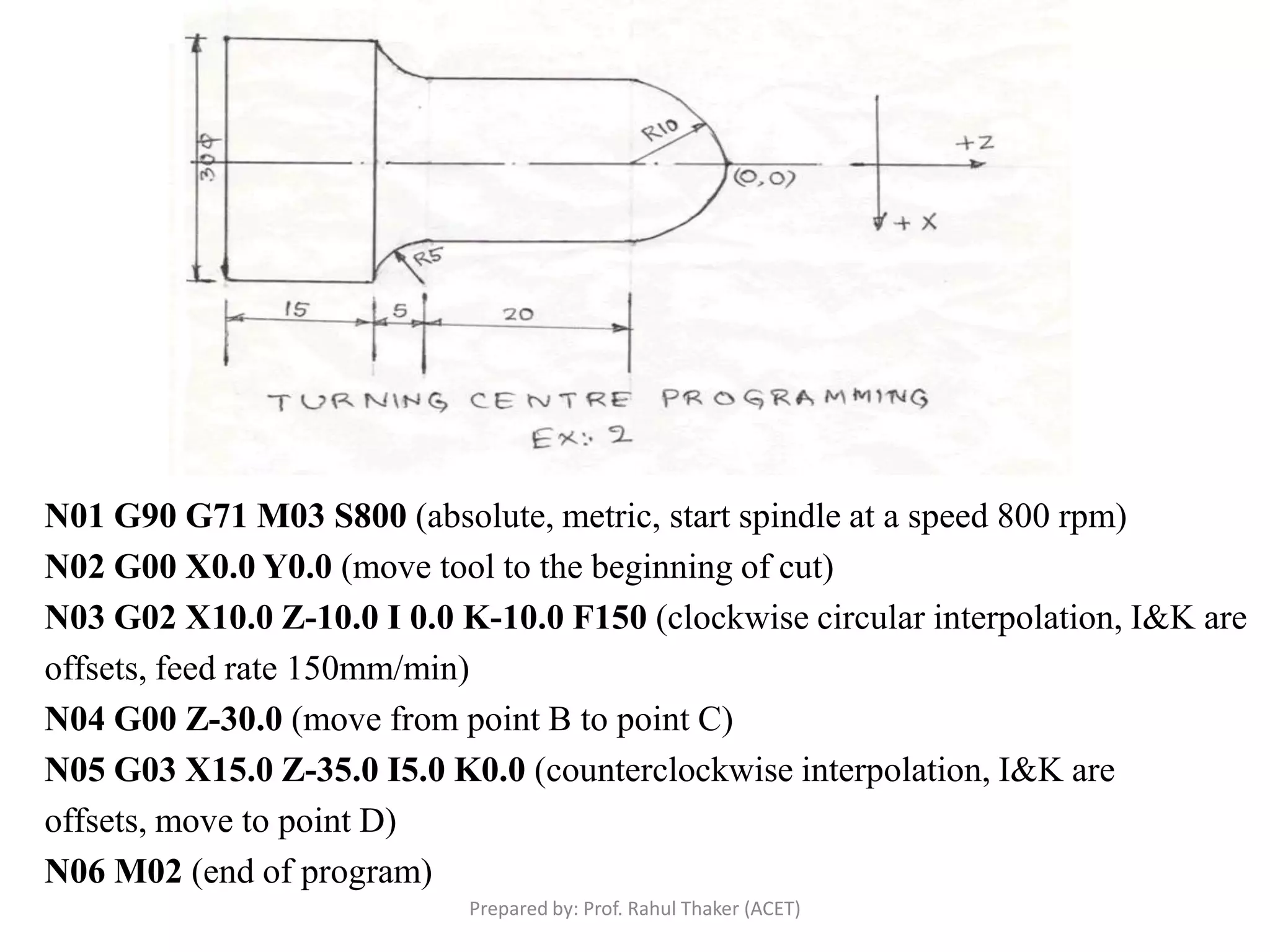

- Programming methods including absolute and incremental coordinate systems, cutter compensation, and subroutines.

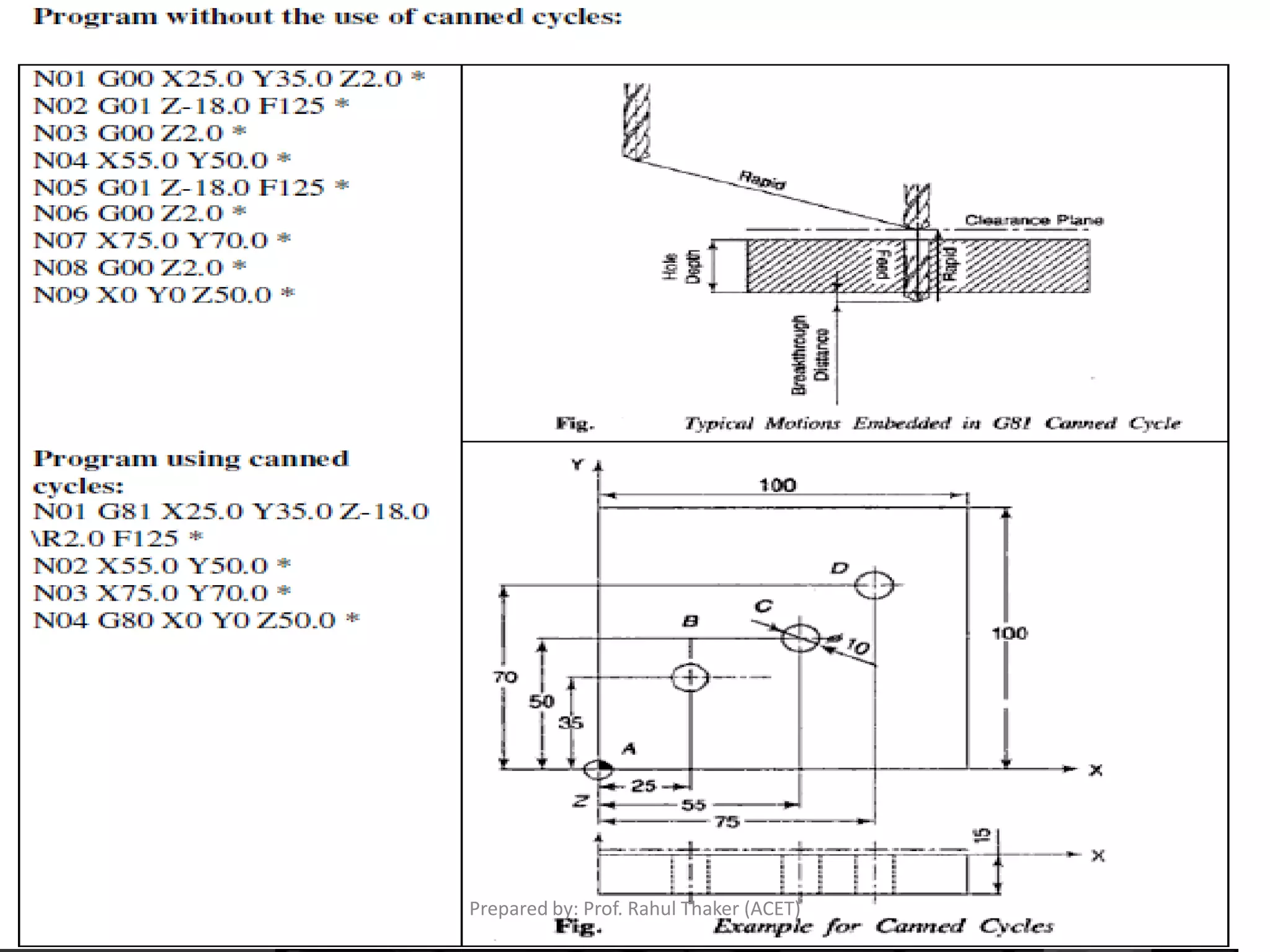

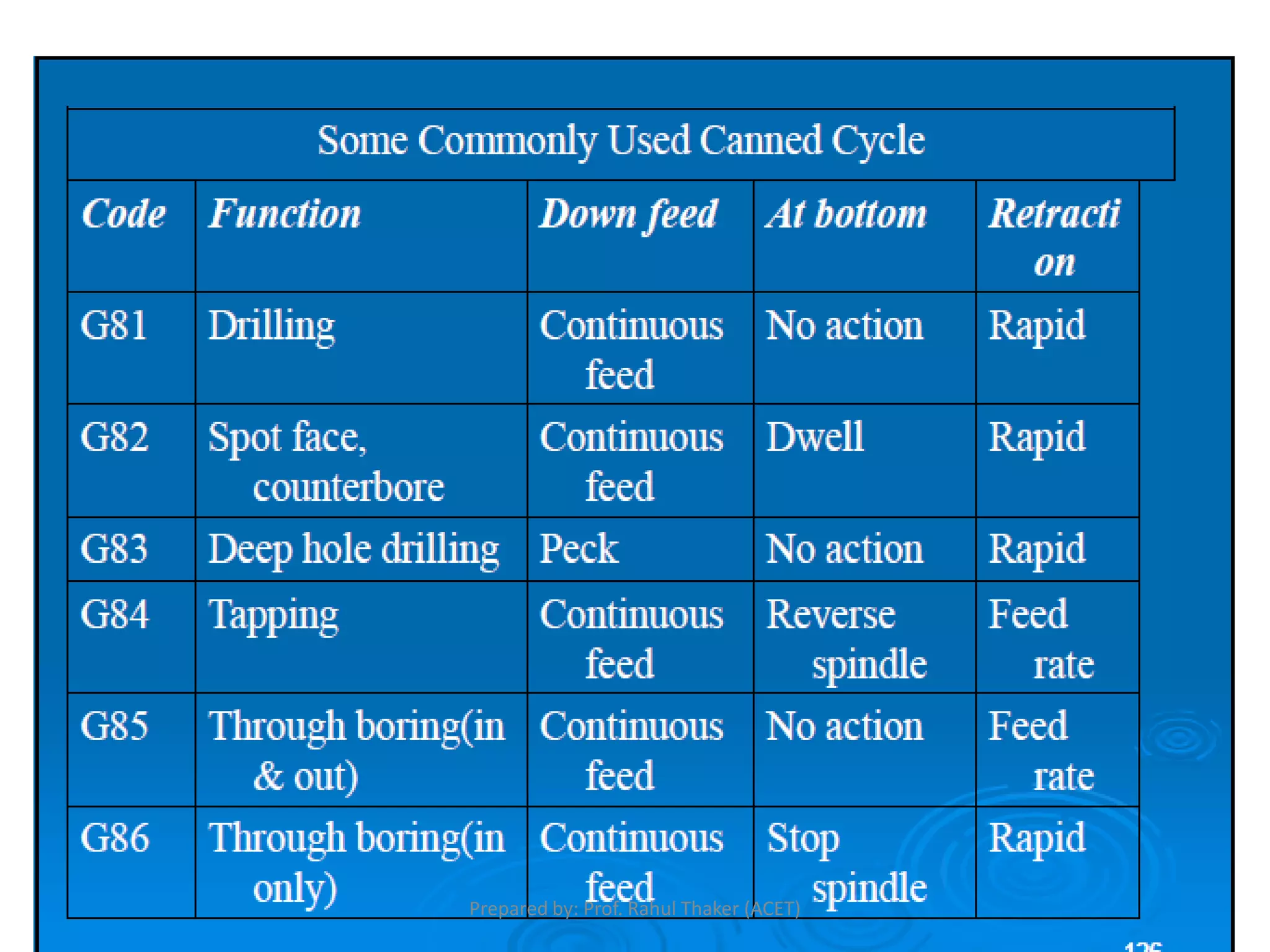

- Canned cycles which are preprogrammed sequences that save time in programming repetitive motions.