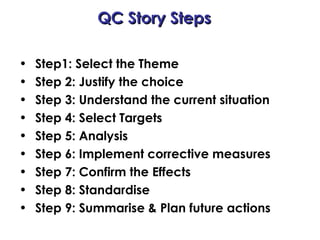

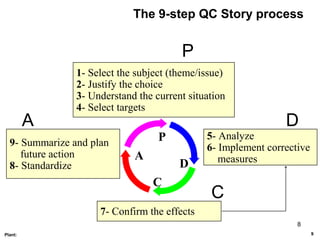

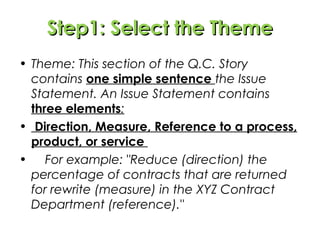

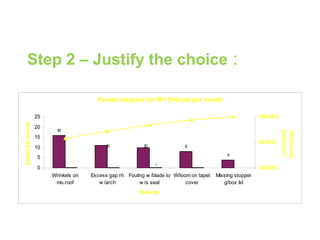

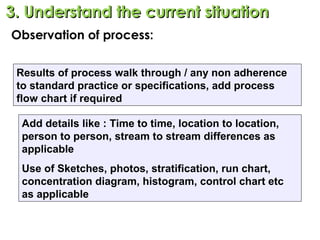

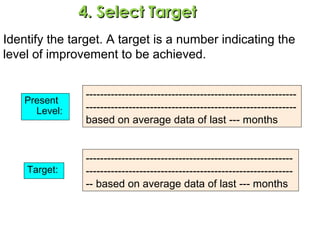

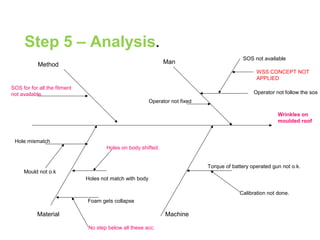

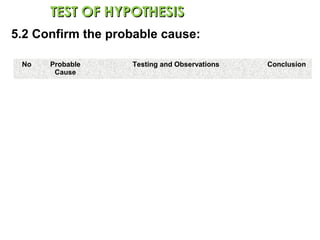

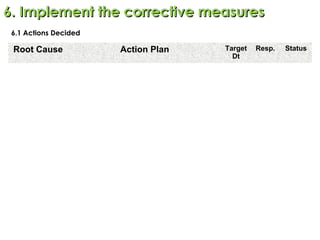

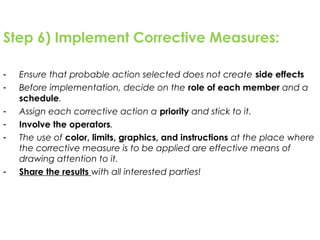

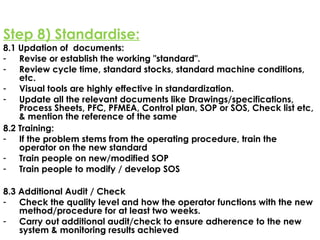

The document provides an introduction and overview of the QC Story methodology, which is a 9-step problem solving technique used to examine facts and data around quality, productivity, cost, logistic, safety and other problems. It involves selecting a theme, justifying the choice, understanding the current situation, setting targets, analyzing causes, implementing corrective measures, confirming effects, standardizing solutions, and planning future actions. Each step is then described in more detail, outlining the key elements and process to be followed at that stage of the QC Story.