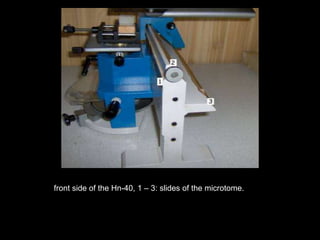

Microtomy is the cutting of thin sections of objects for microscopic examination using a microtome. A microtome uses a mechanical device to precisely cut extremely thin, uniform sections, overcoming limitations of free-hand sectioning. There are two main types of microtomes: those where the block remains stationary and the knife moves, and those where the block moves across a stationary knife. Sledge microtomes are used to cut large samples embedded in paraffin, allowing sections from 1-60 μm to be cut.