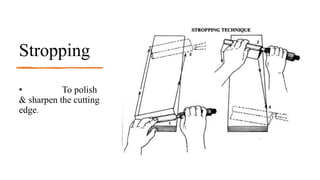

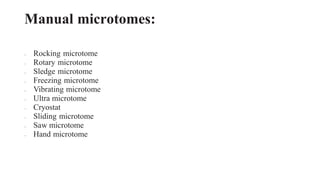

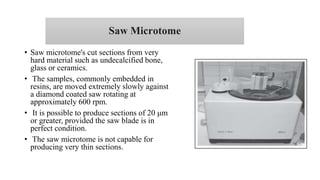

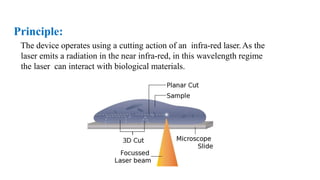

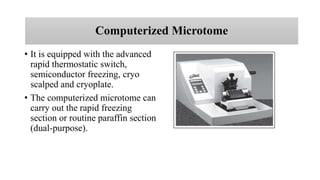

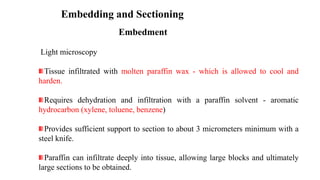

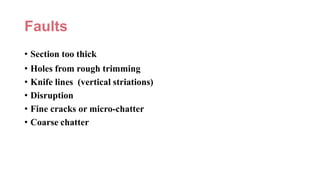

Microtomy is the process of cutting thin tissue sections for microscopic examination. It involves using a microtome, a mechanical device that cuts very thin and uniform slices. There are various types of microtomes classified based on their cutting mechanism, such as manual microtomes like sliding, rotary, and cryostat microtomes, and automatic microtomes. Microtomes can also be classified based on the material of the knife edge used such as steel, glass, diamond, and sapphire knives. Proper sample preparation and microtome maintenance are important to obtain high quality sections without artifacts.