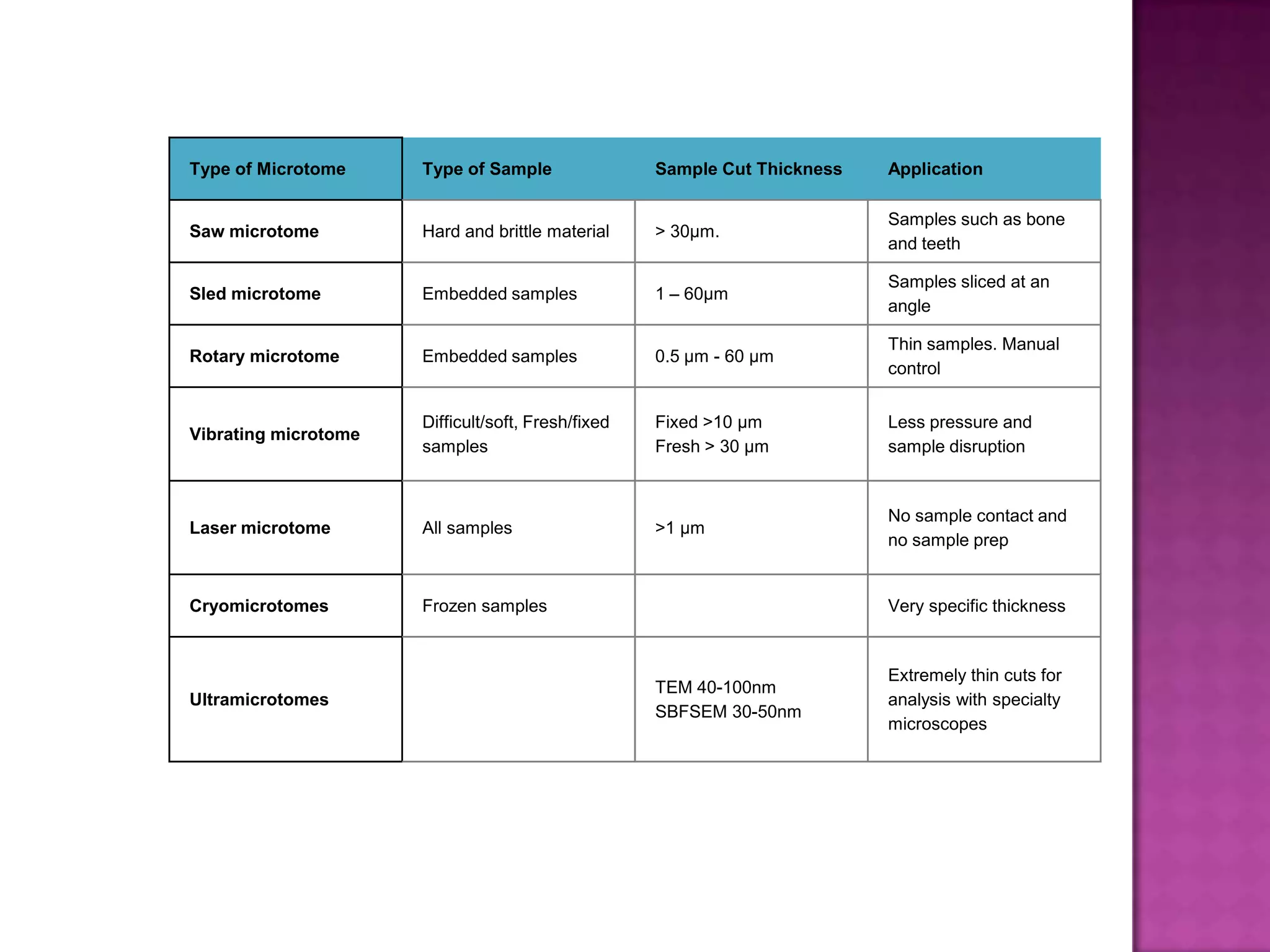

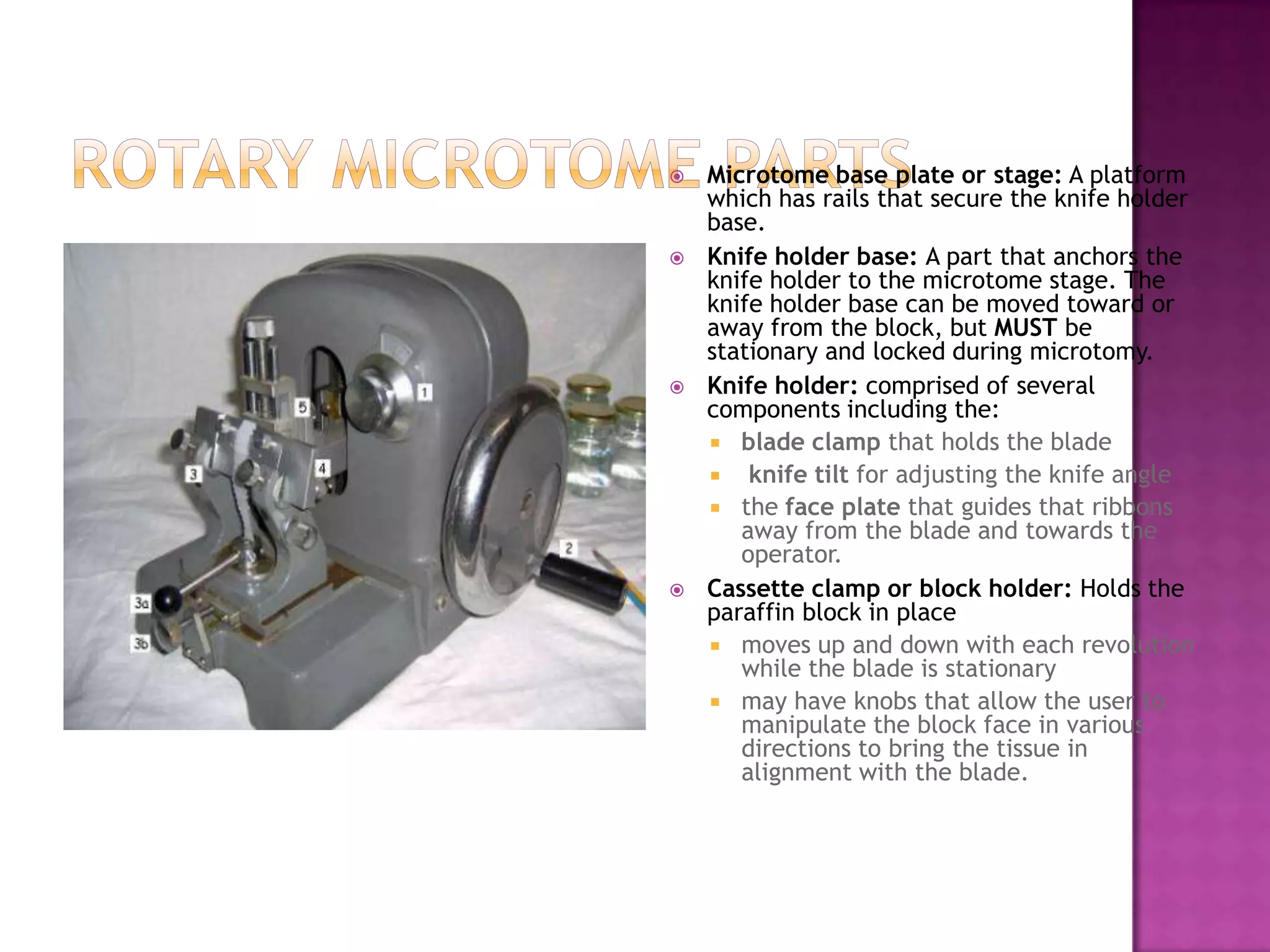

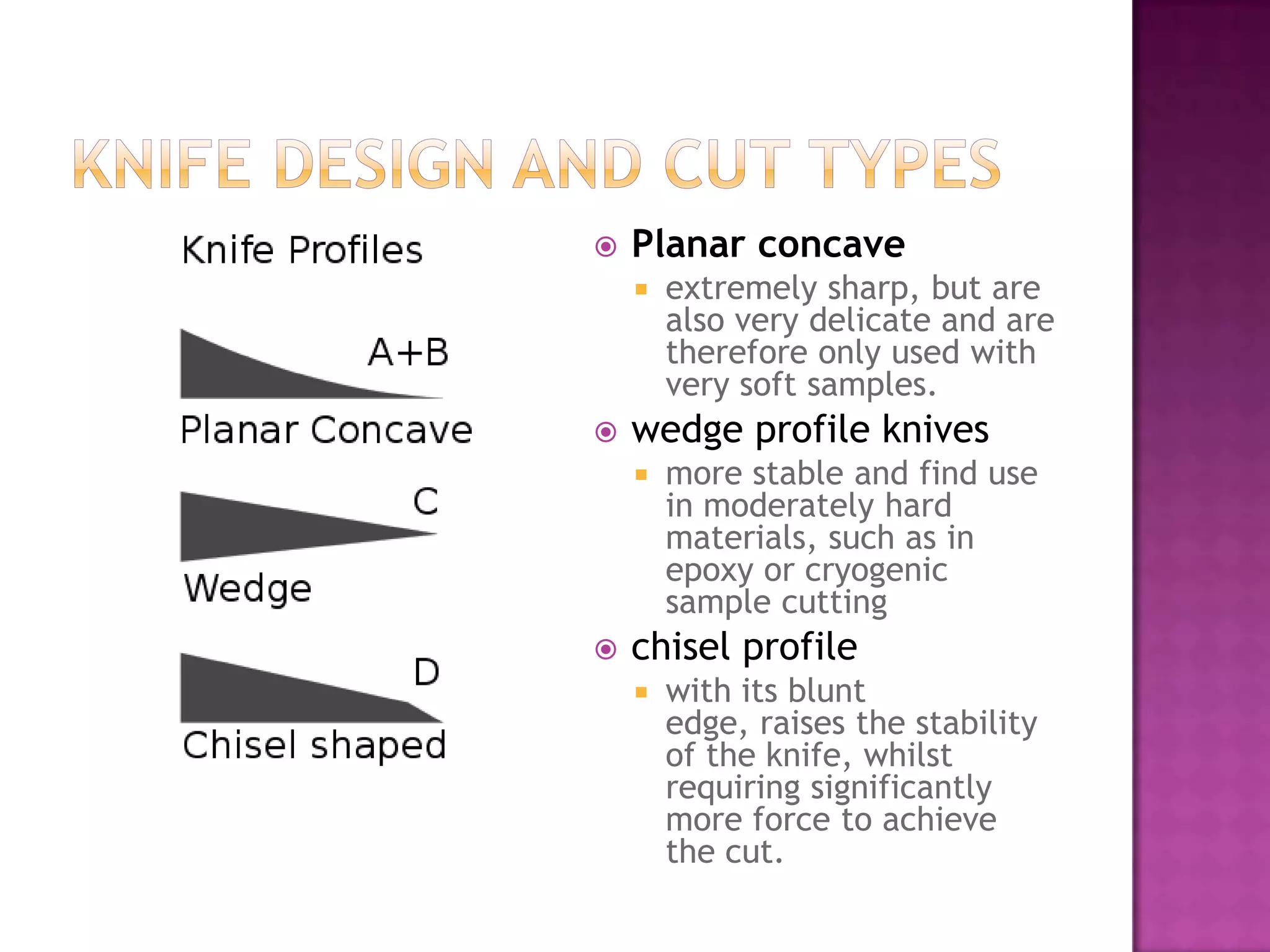

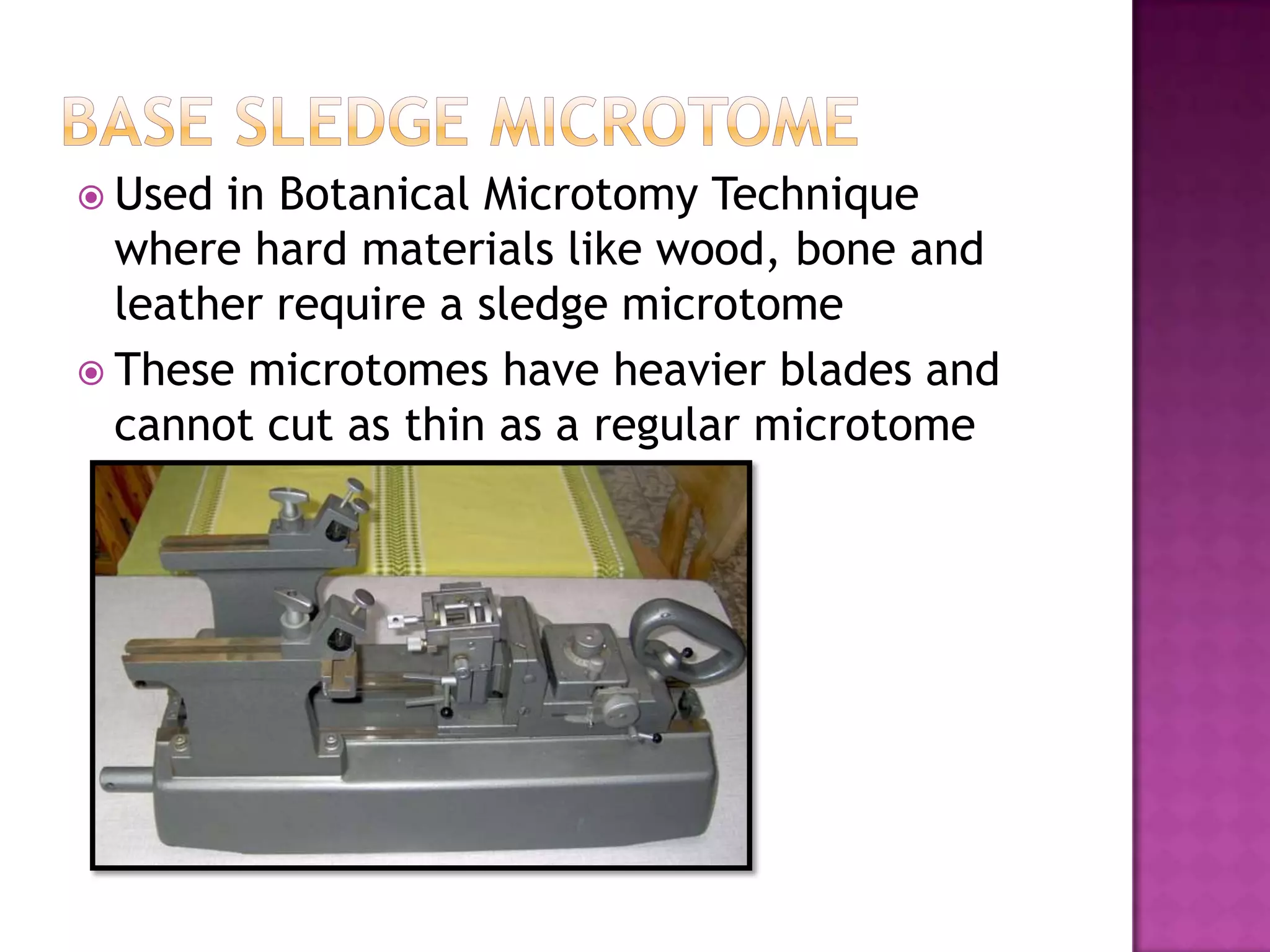

This document provides information about various types of microtomes used to cut extremely thin sections of samples for examination under microscopes. It describes glass and diamond blades, base sledge and rotary microtomes, and gives details about their components and operating principles. Different microtomes are suited for cutting particular materials to specific thicknesses for applications in light microscopy, electron microscopy, and histology.