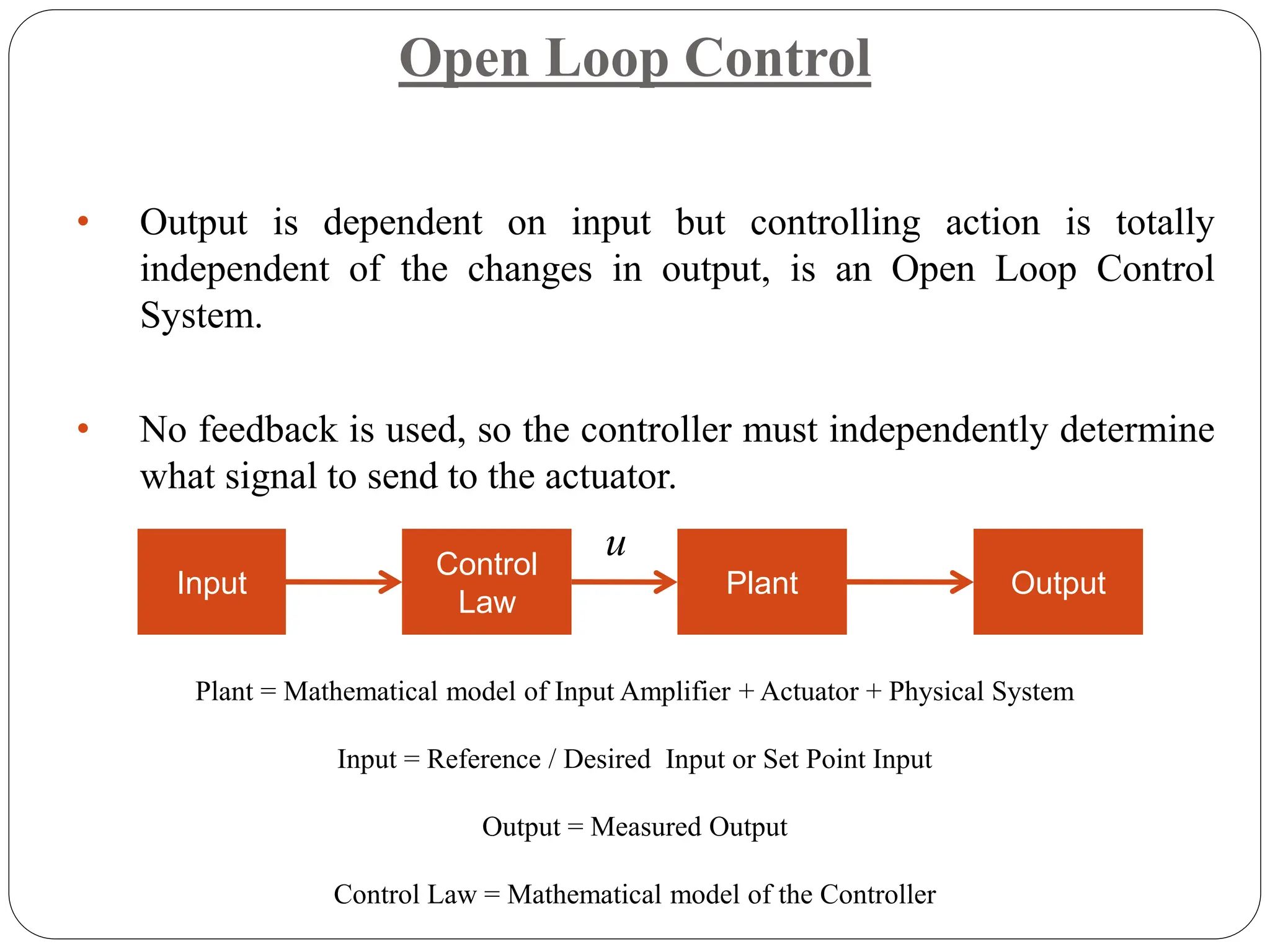

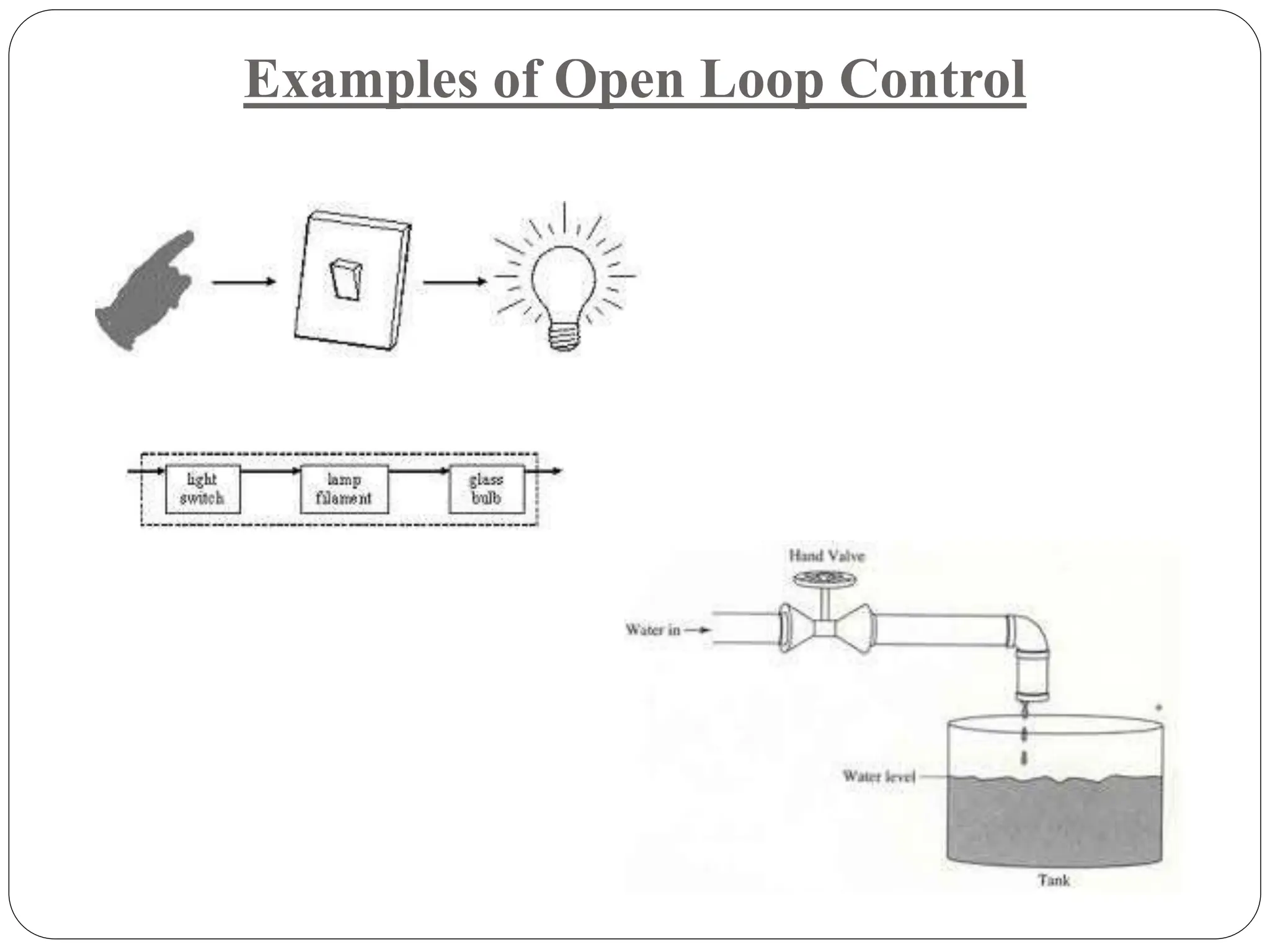

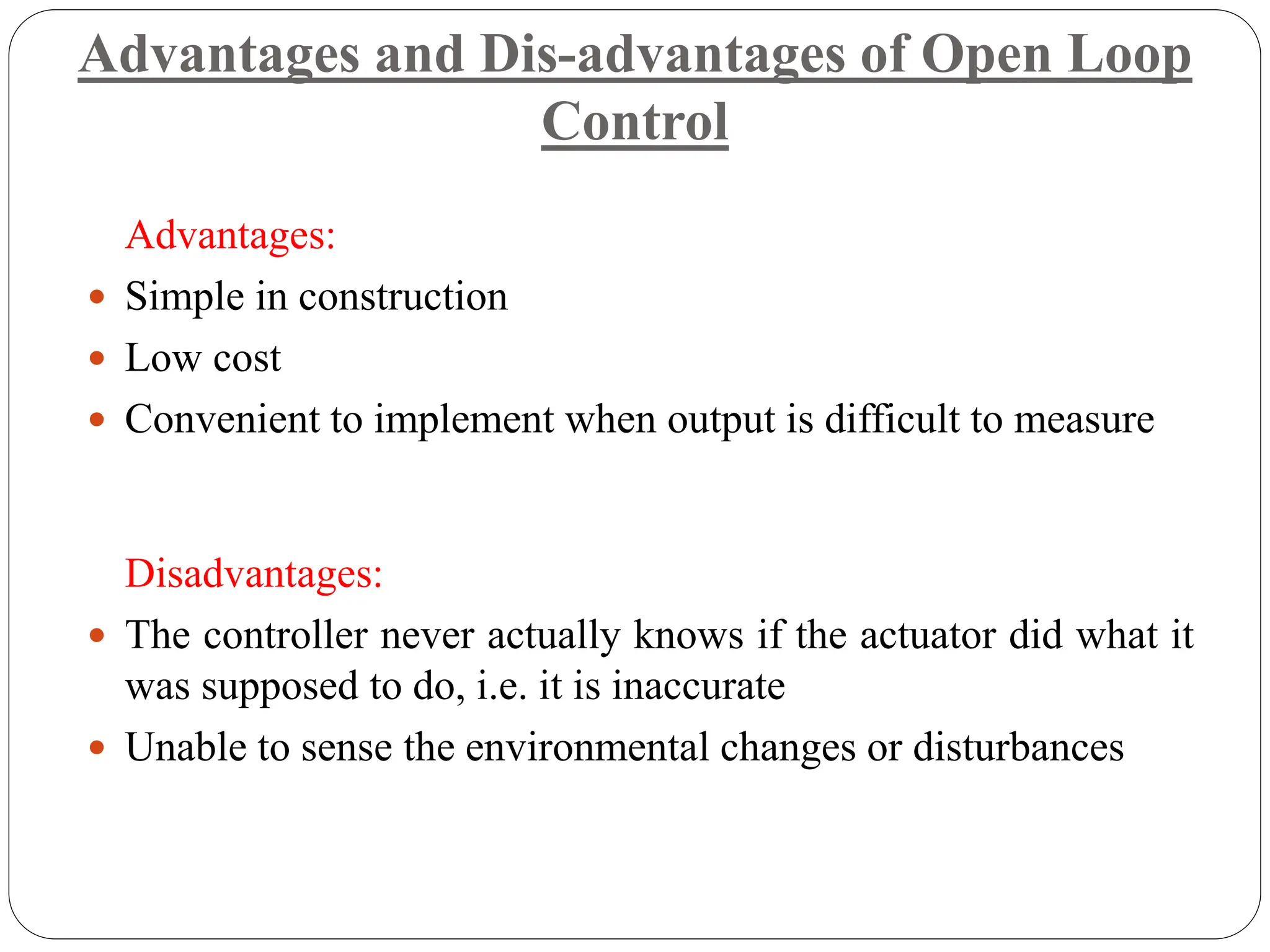

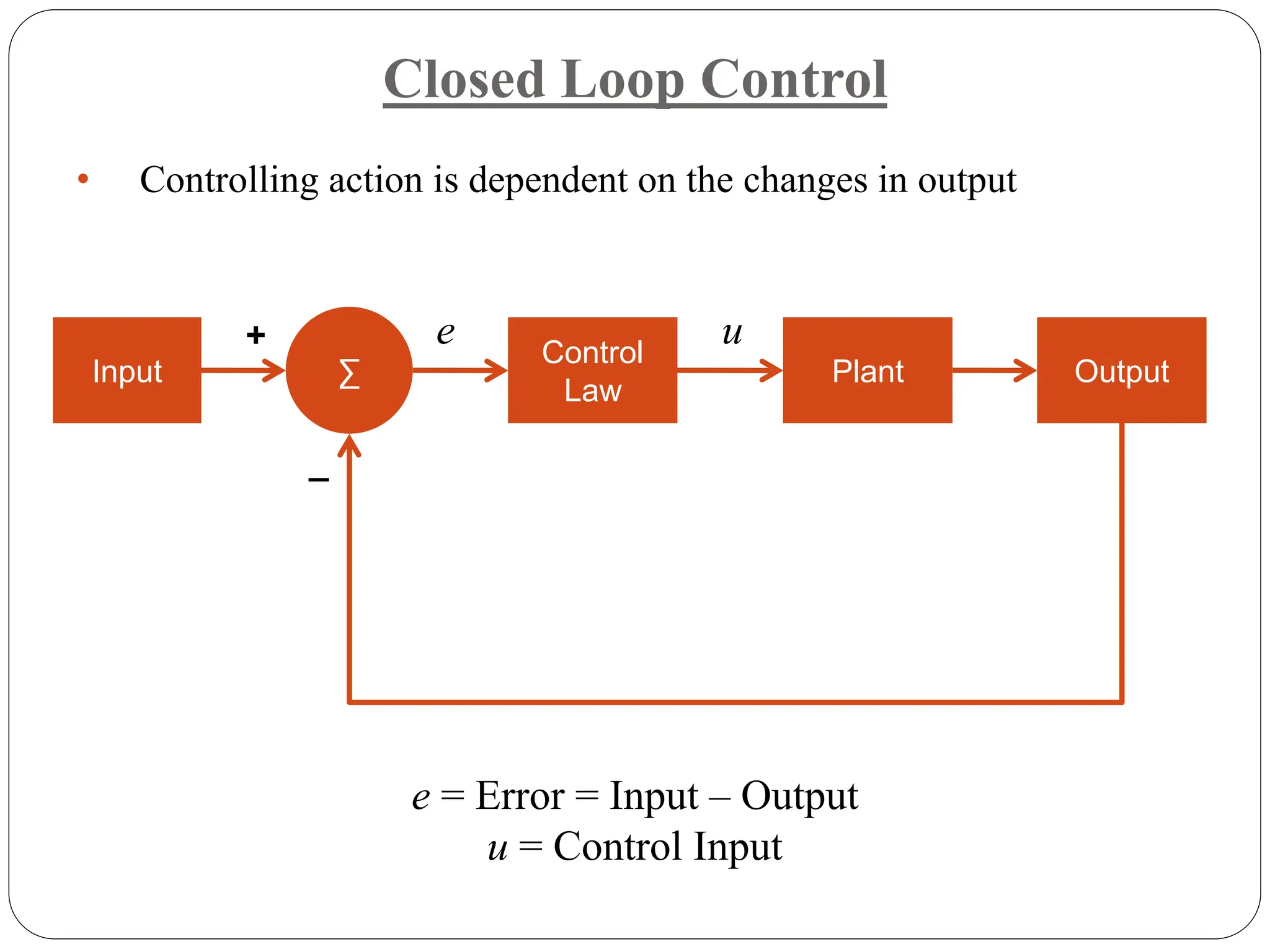

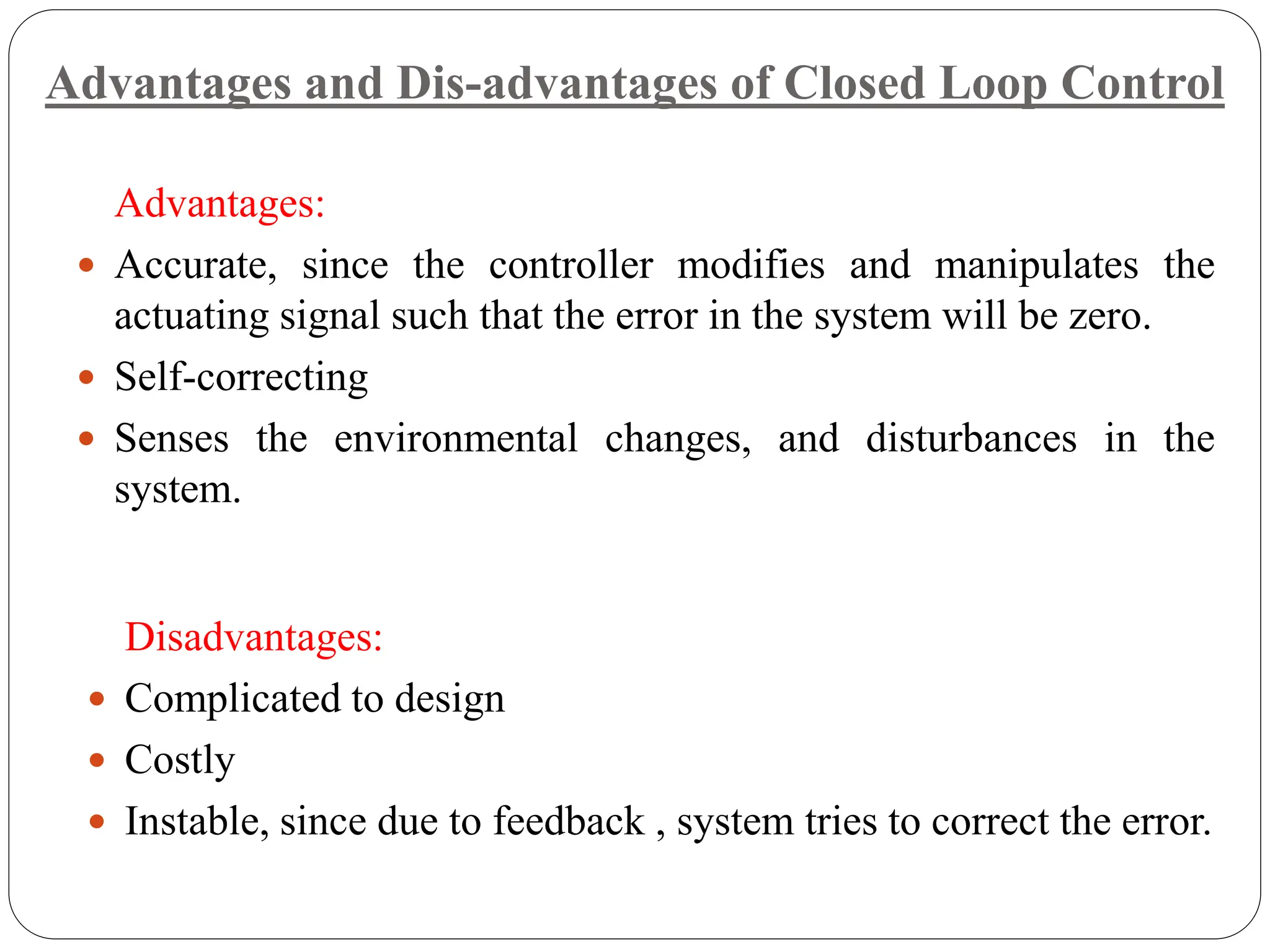

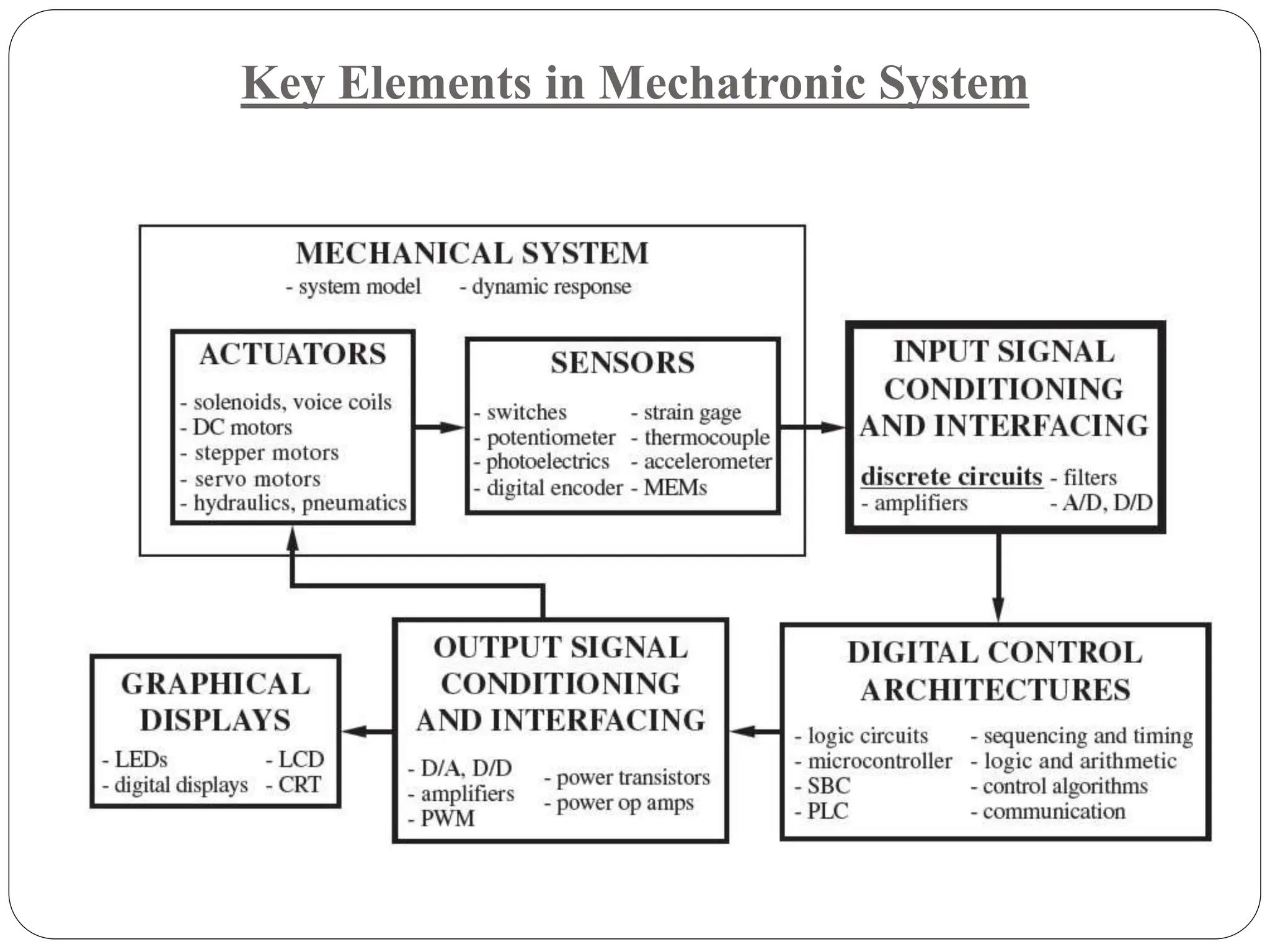

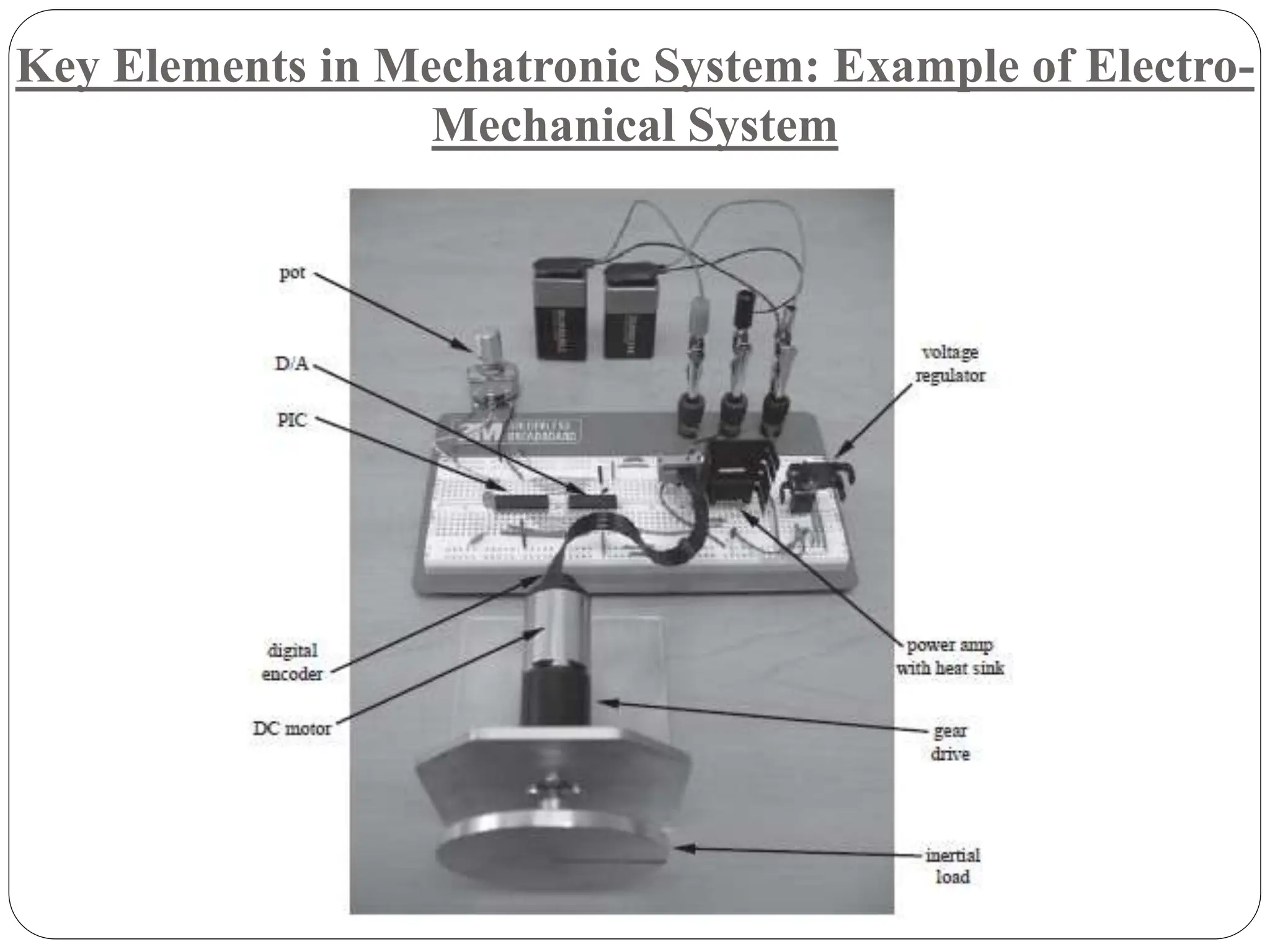

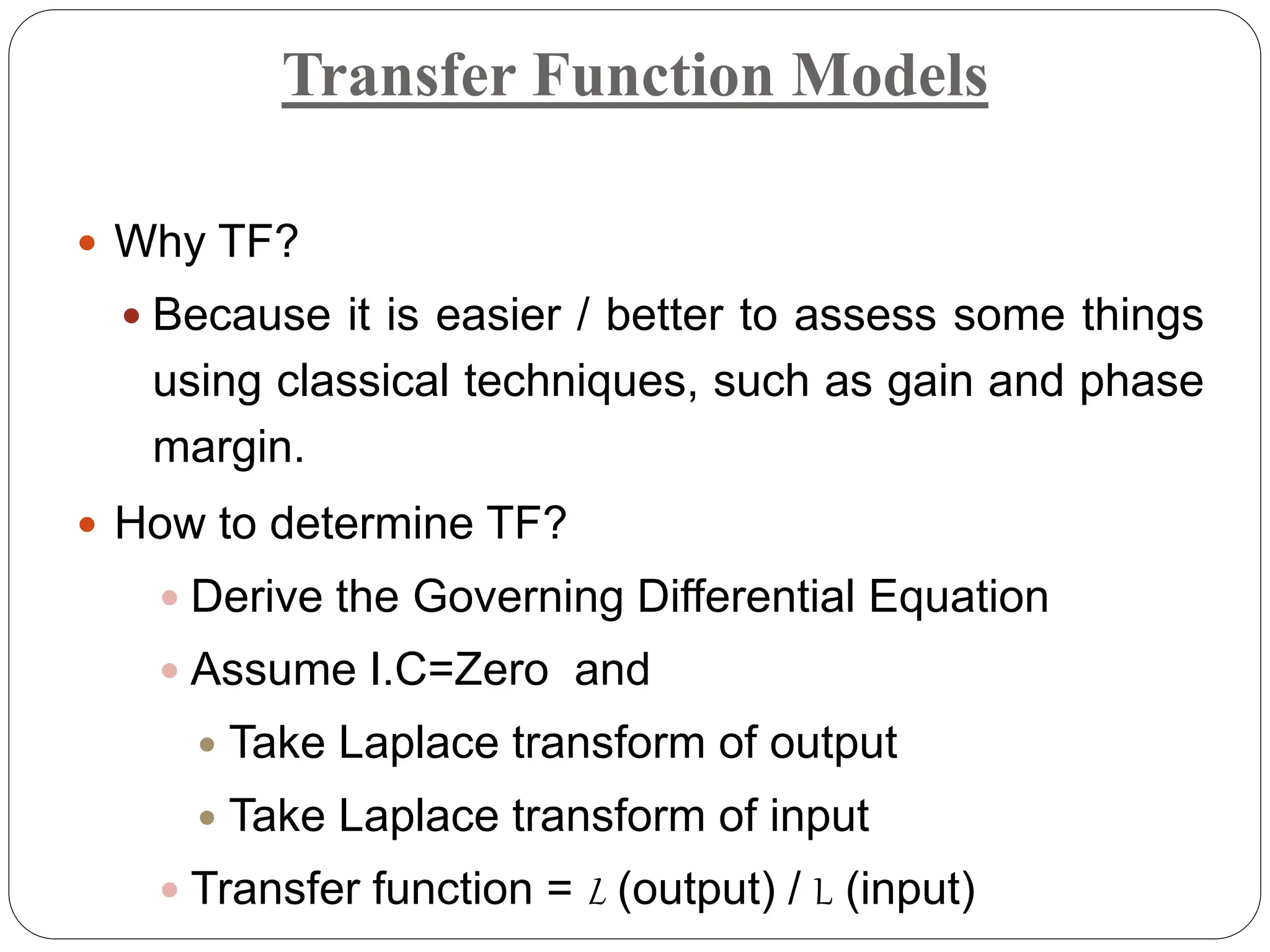

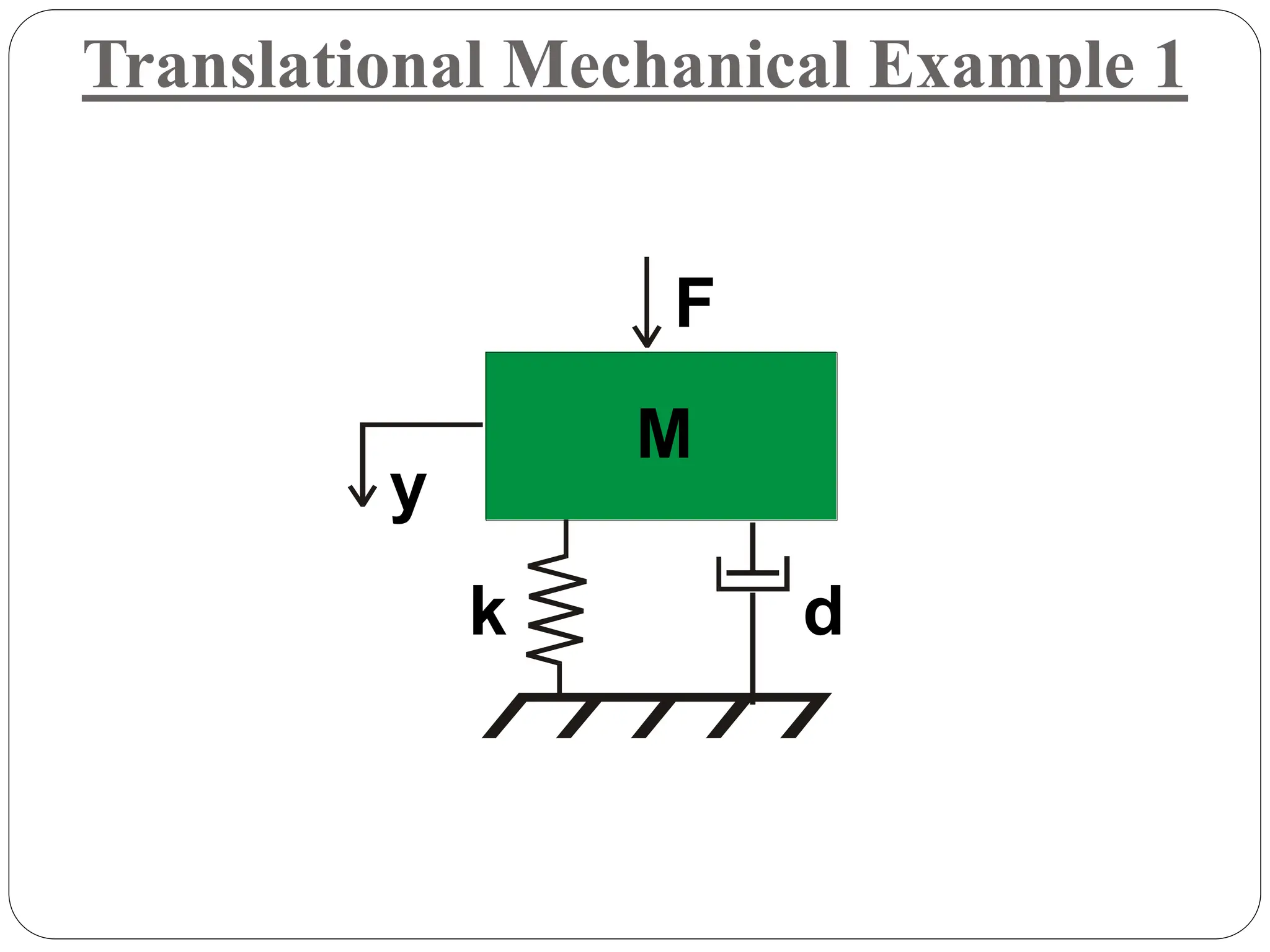

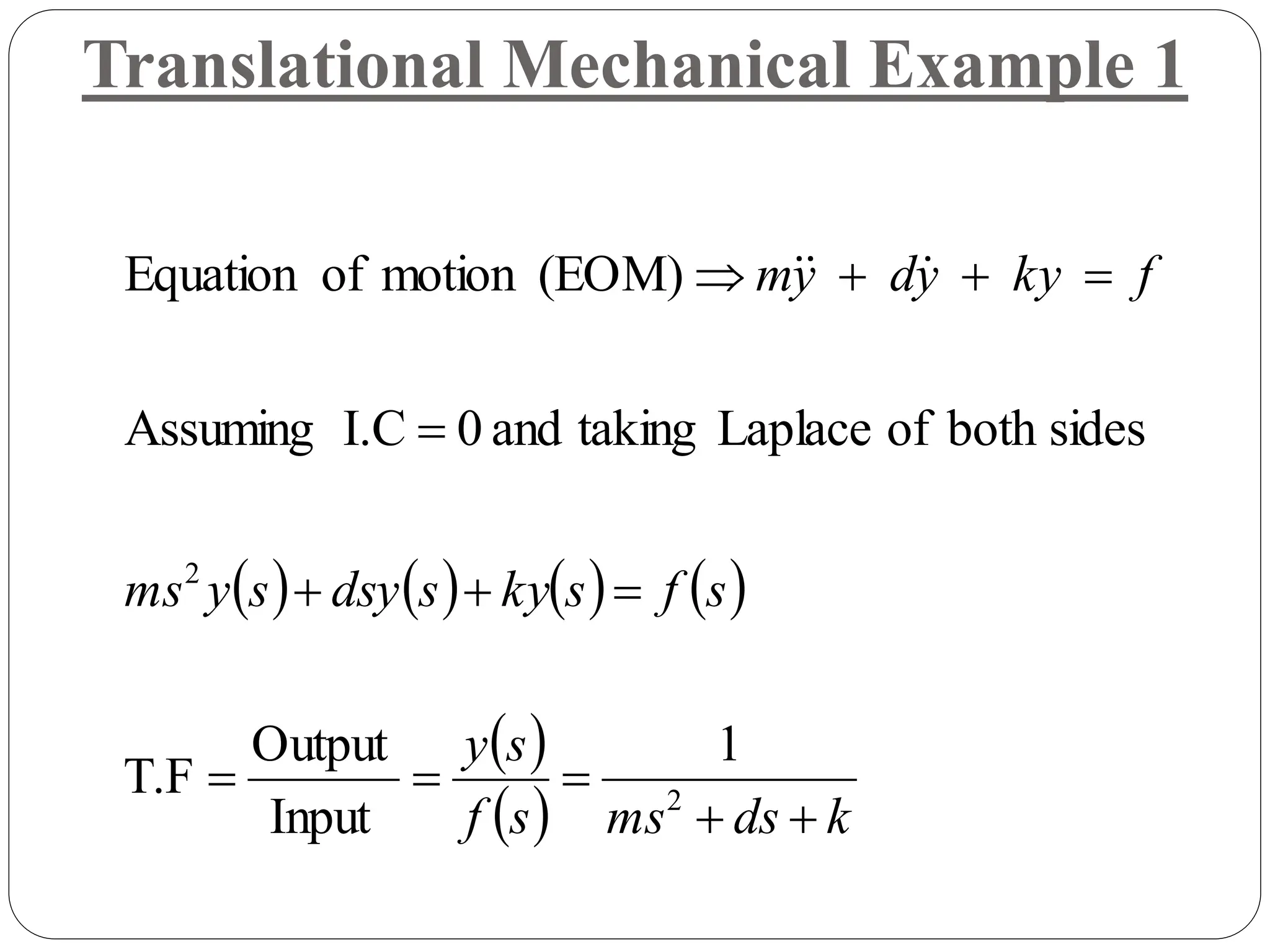

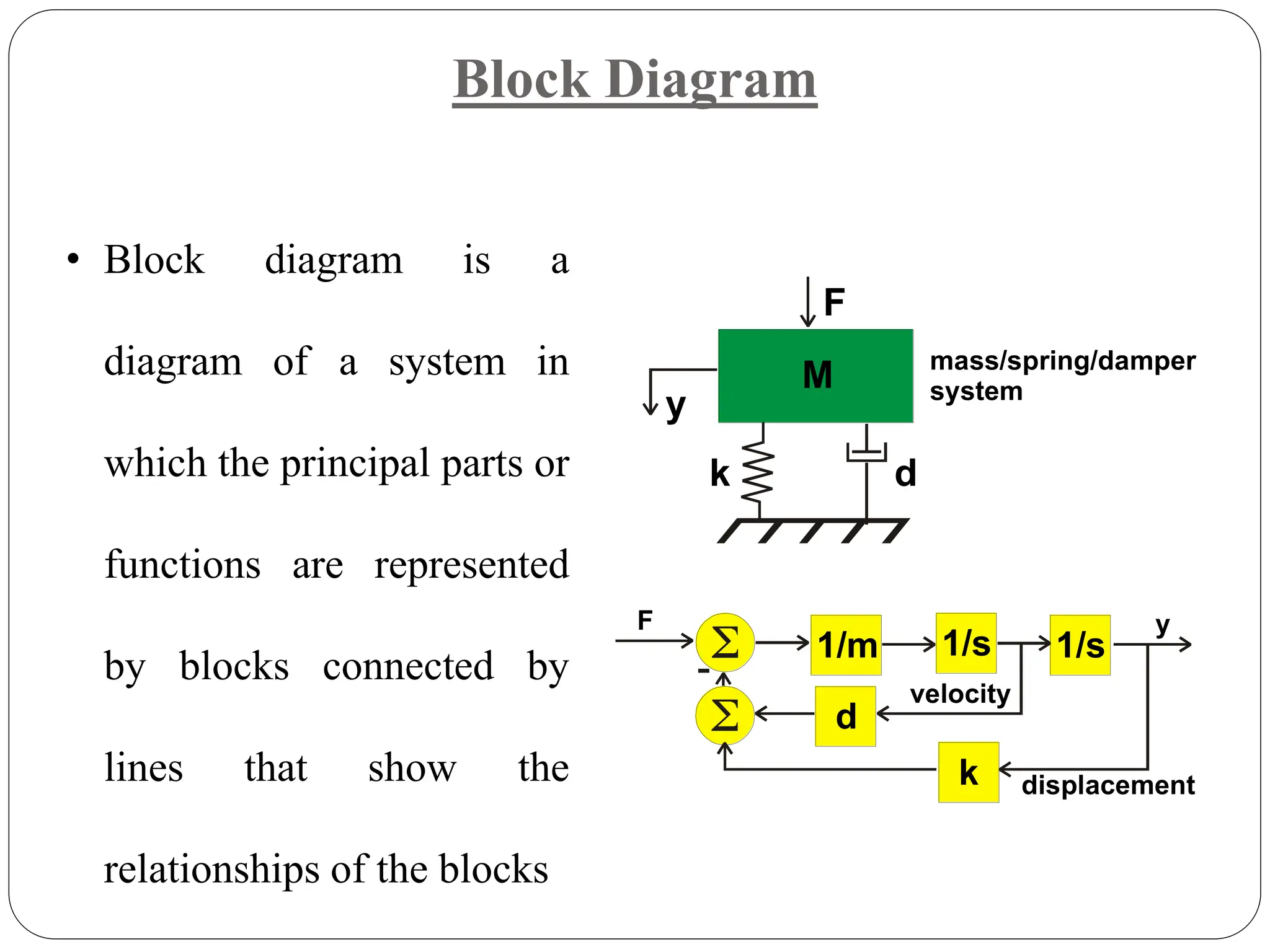

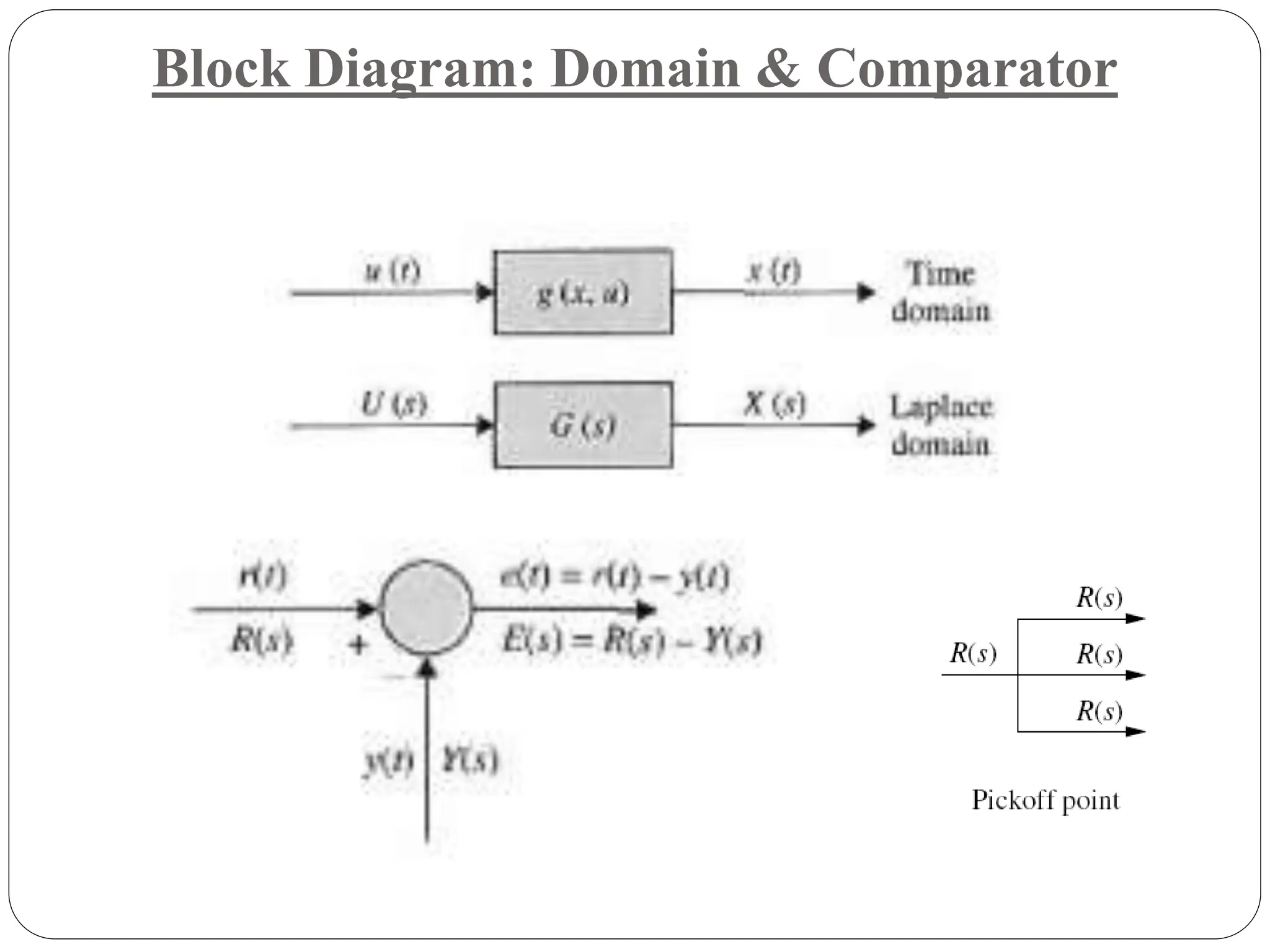

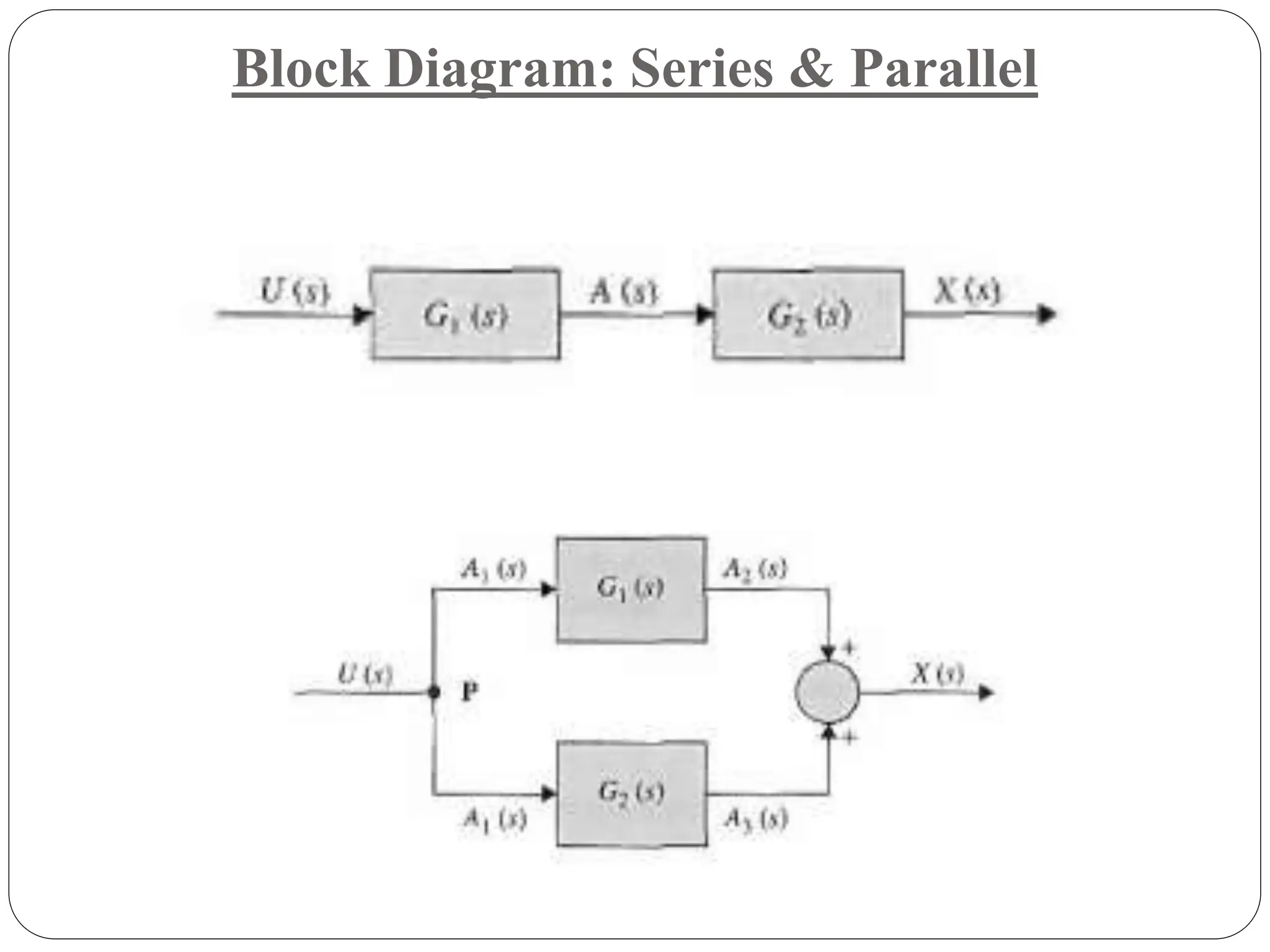

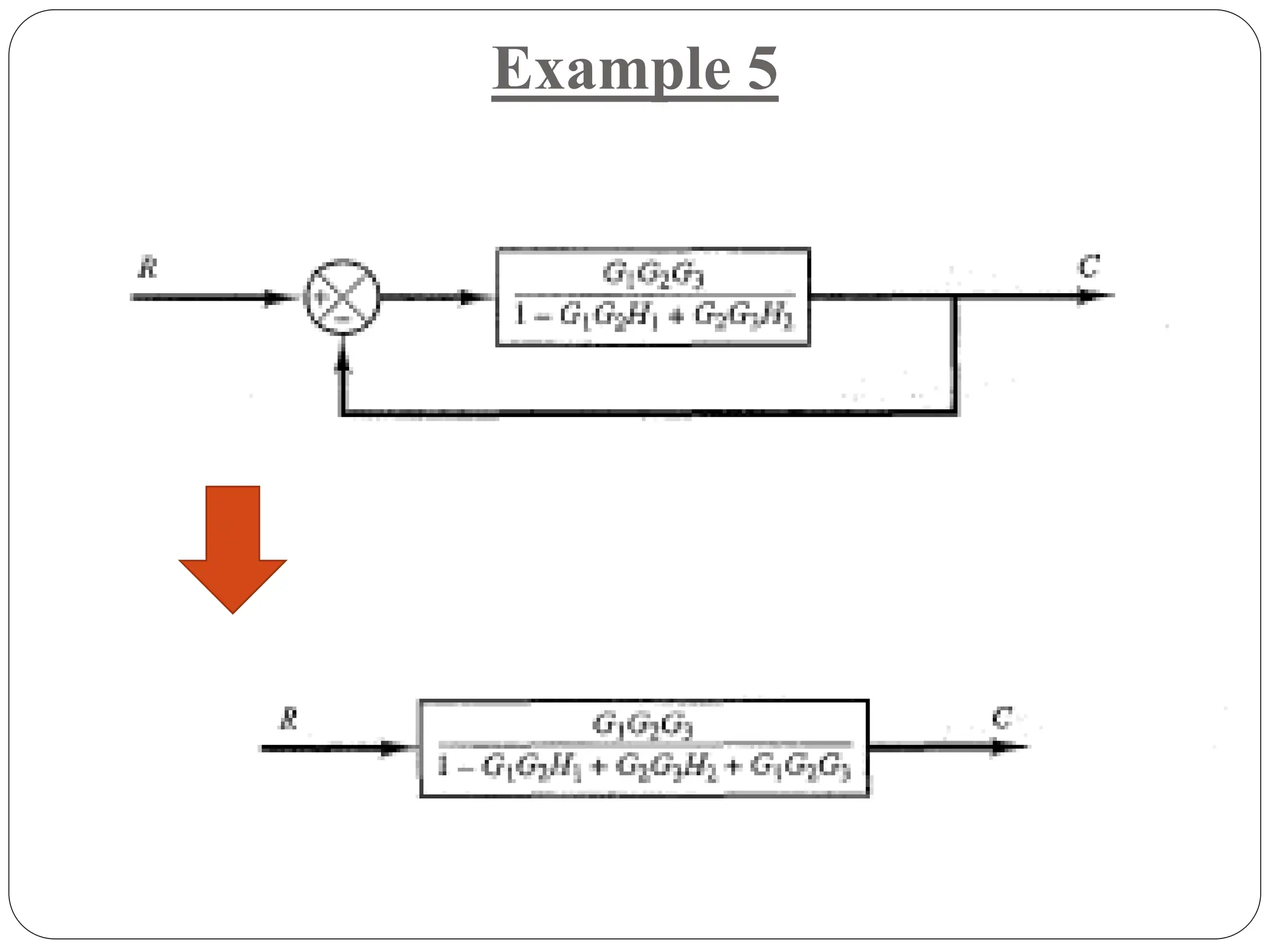

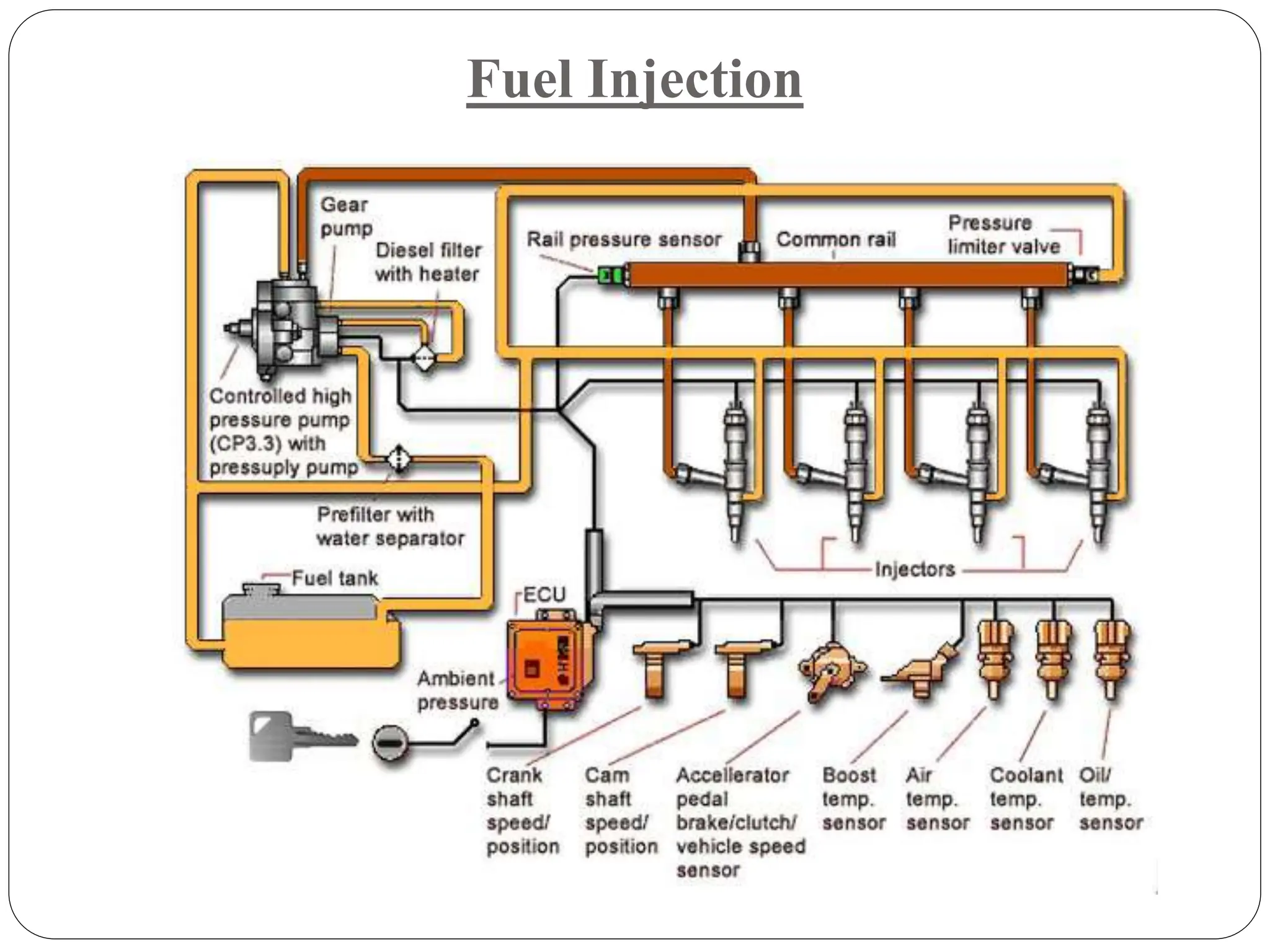

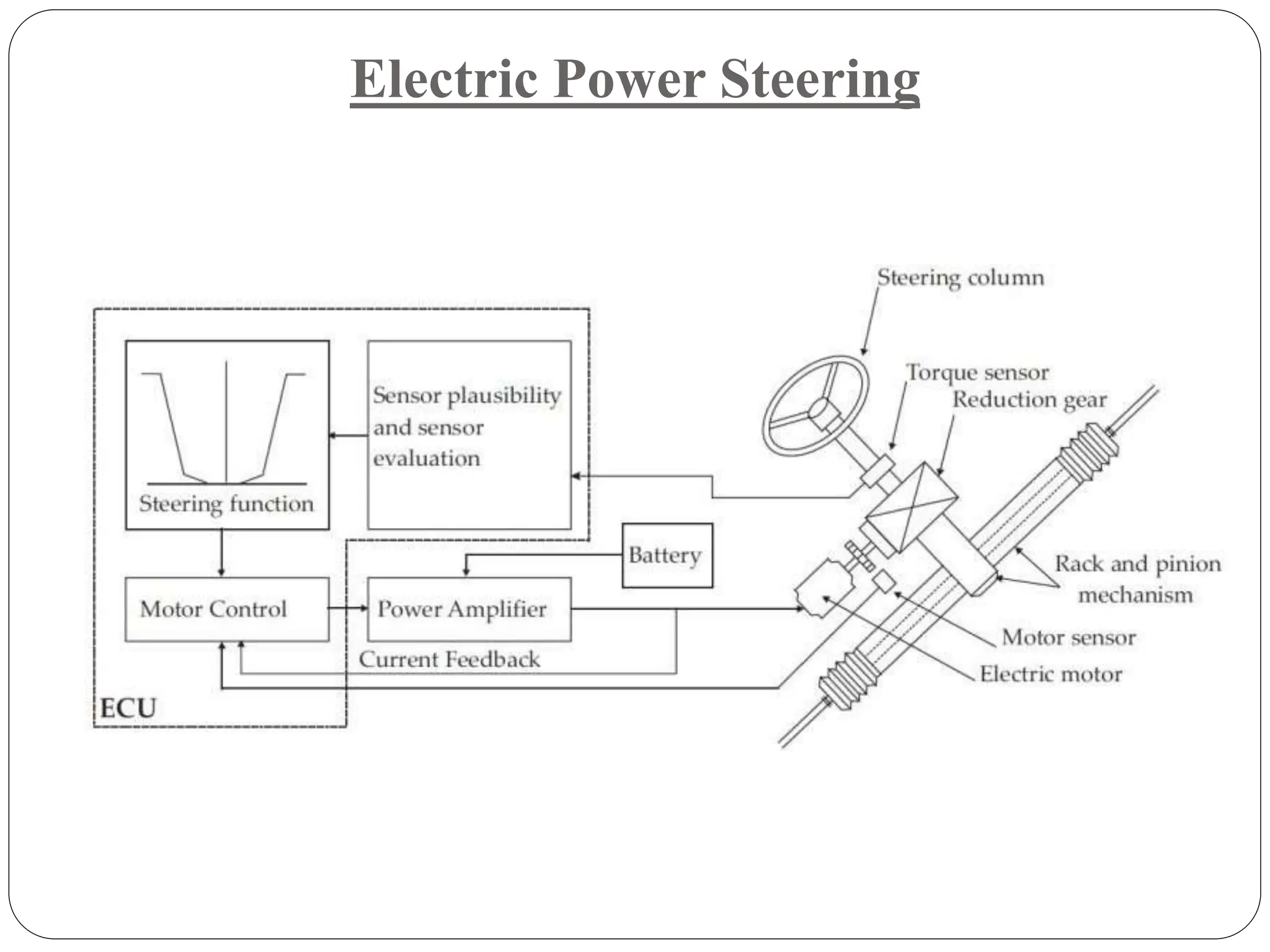

The document outlines lecture notes on mechatronics, covering control systems, key elements, representations as block diagrams, and various applications in industries. It emphasizes understanding concepts such as transfer functions, PID control, PLC systems, and the differences between open and closed-loop control systems. The document also includes objectives, outcomes, and references for further reading in the field of mechatronics.