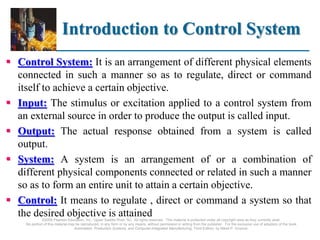

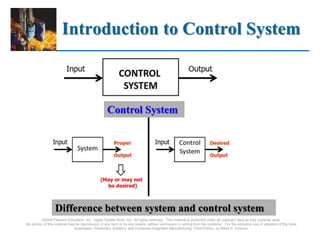

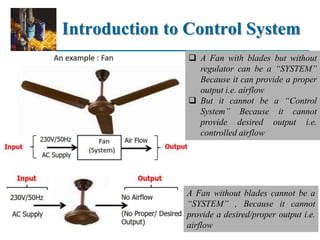

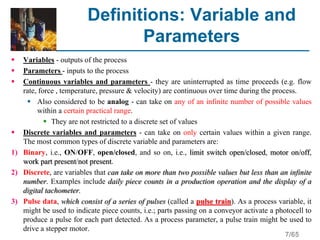

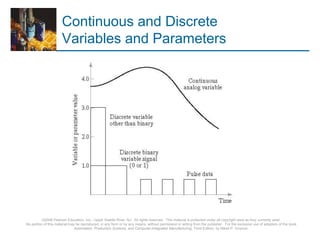

1. The document discusses control systems used in industrial automation and manufacturing. It defines control systems and their key components like input, output, and feedback loops.

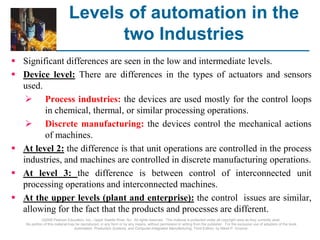

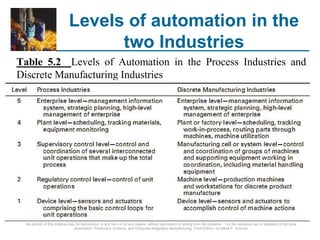

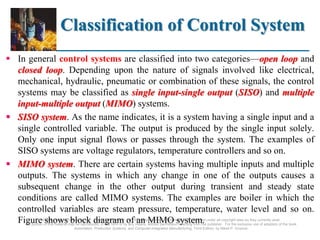

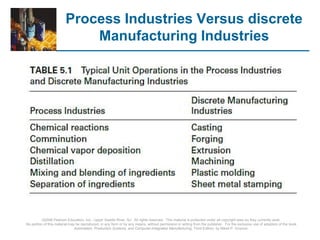

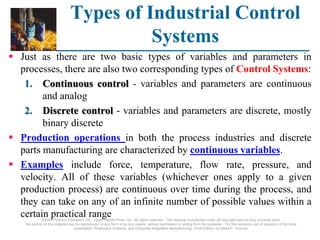

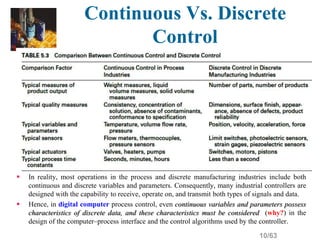

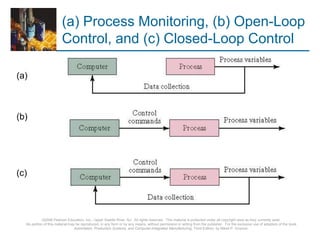

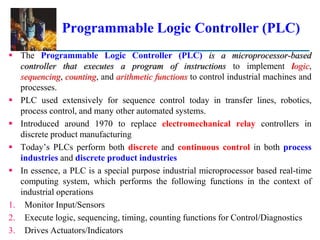

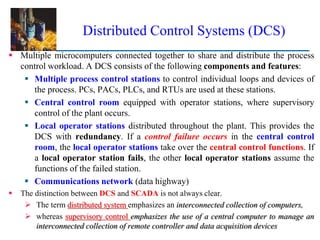

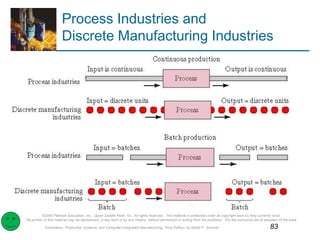

2. Control systems are classified based on whether they are open or closed loop, linear or non-linear, single input-single output or multiple input-multiple output. They also vary between process industries and discrete manufacturing.

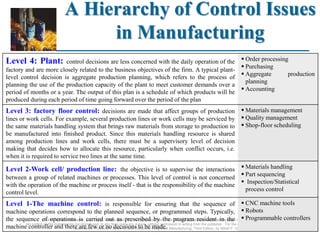

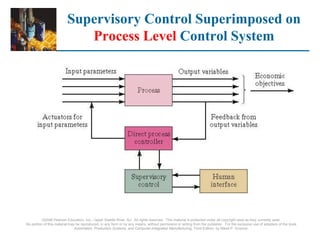

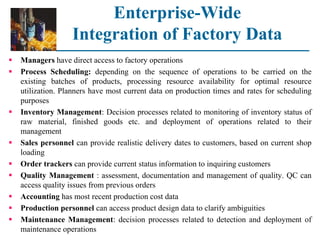

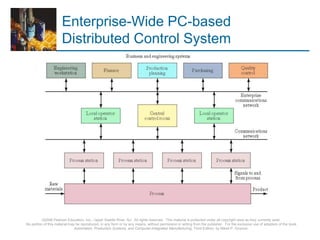

3. Different levels of control systems are described from machine control to plant control, with examples of decisions made at each level.