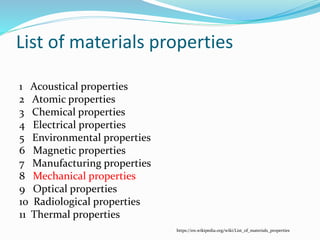

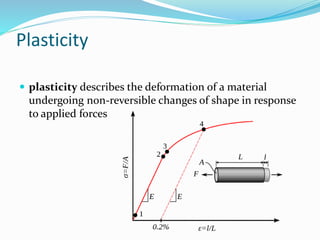

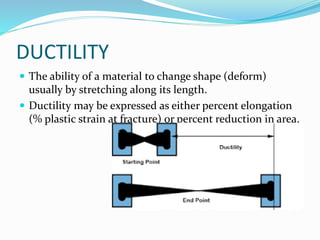

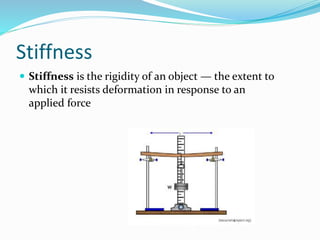

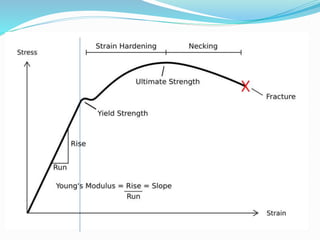

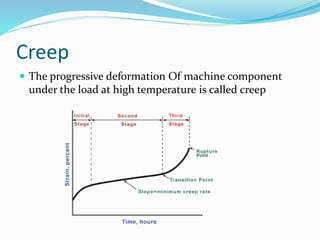

This document discusses various material properties including mechanical properties. It lists 11 categories of material properties and provides definitions and explanations for several important mechanical properties. These include fatigue strength, endurance limit, tensile strength, compressive strength, elasticity, plasticity, ductility, brittleness, malleability, toughness, stiffness, resilience, hardness, and creep. The document serves to define and explain key terms related to the mechanical properties of materials.