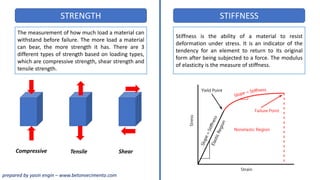

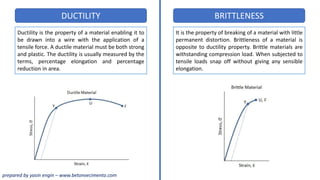

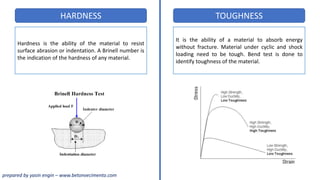

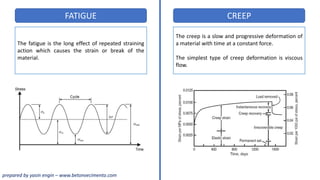

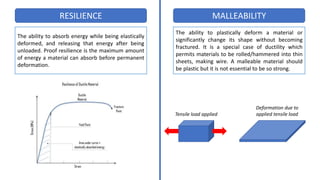

The document discusses various mechanical properties of materials including strength, stiffness, elasticity, plasticity, ductility, brittleness, hardness, toughness, fatigue, creep, resilience, and malleability. Strength is the ability to withstand load before failure. Stiffness is the resistance to deformation under stress. Elasticity and plasticity refer to a material's ability to return to its original shape or retain a deformation, respectively. Ductility allows drawing a material into a wire while brittleness causes brittle fracture. Hardness measures resistance to surface indentation. Toughness is the ability to absorb energy without fracturing. Fatigue and creep describe effects of repeated or sustained loading. Resilience and malleability