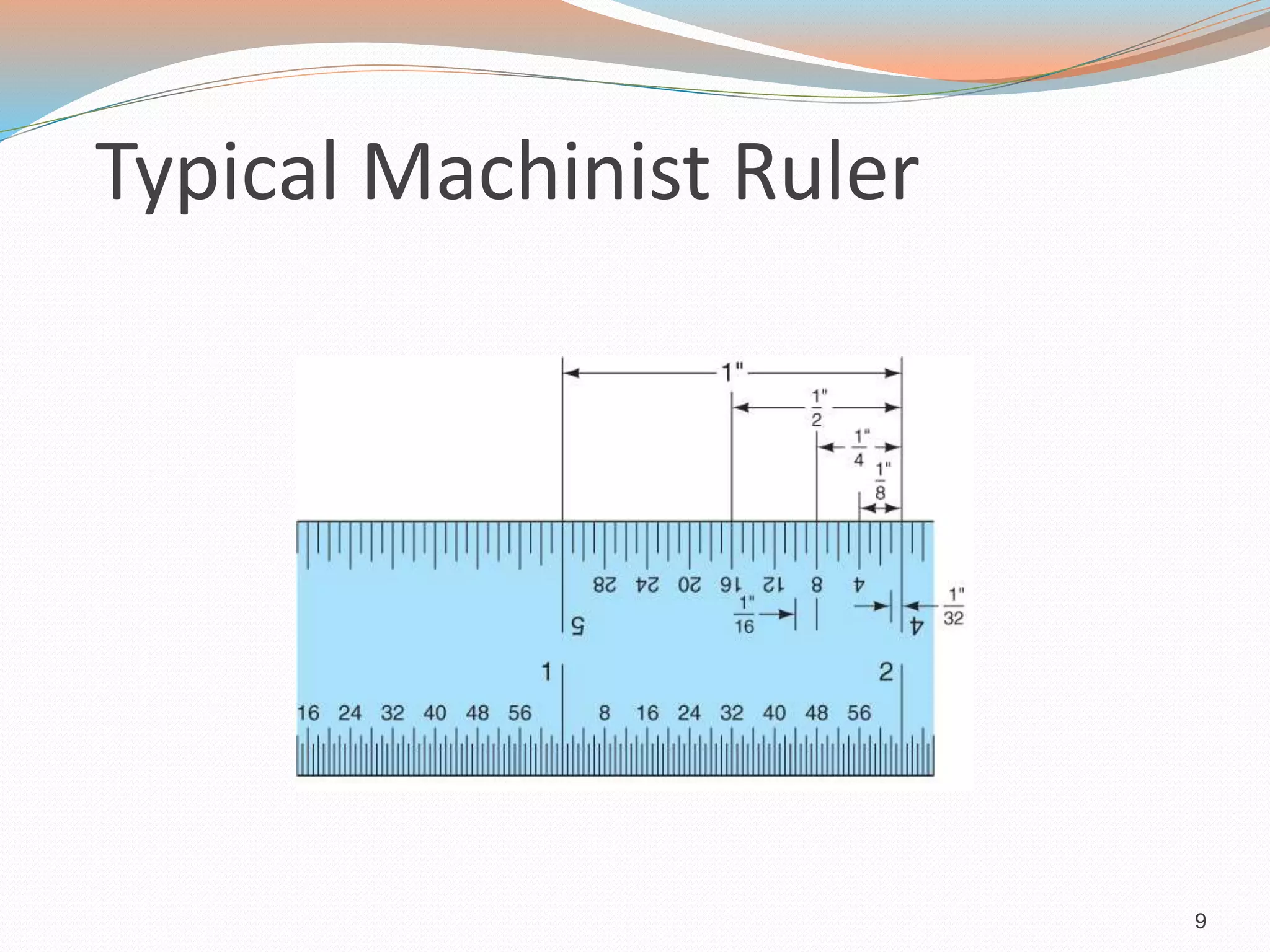

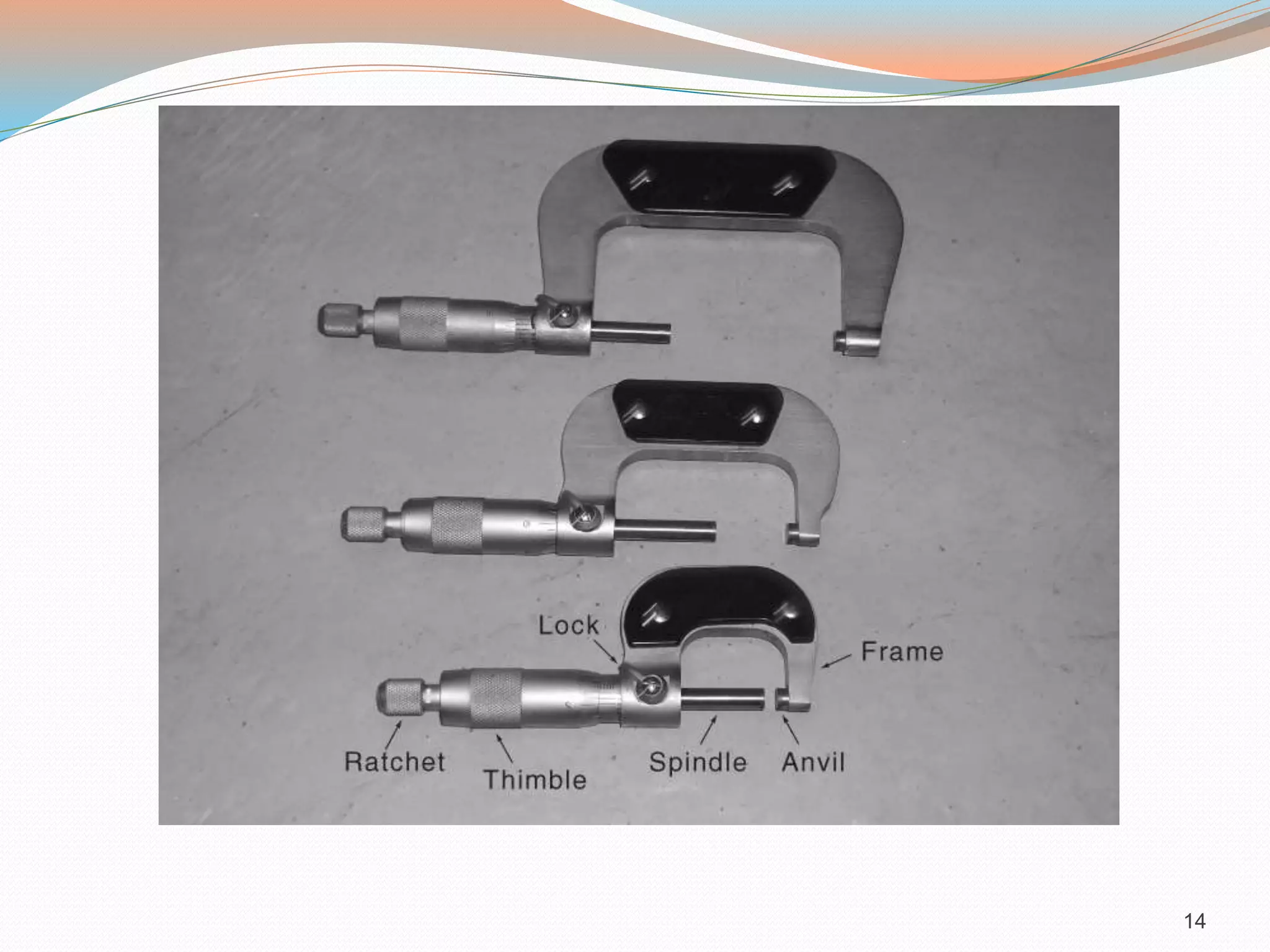

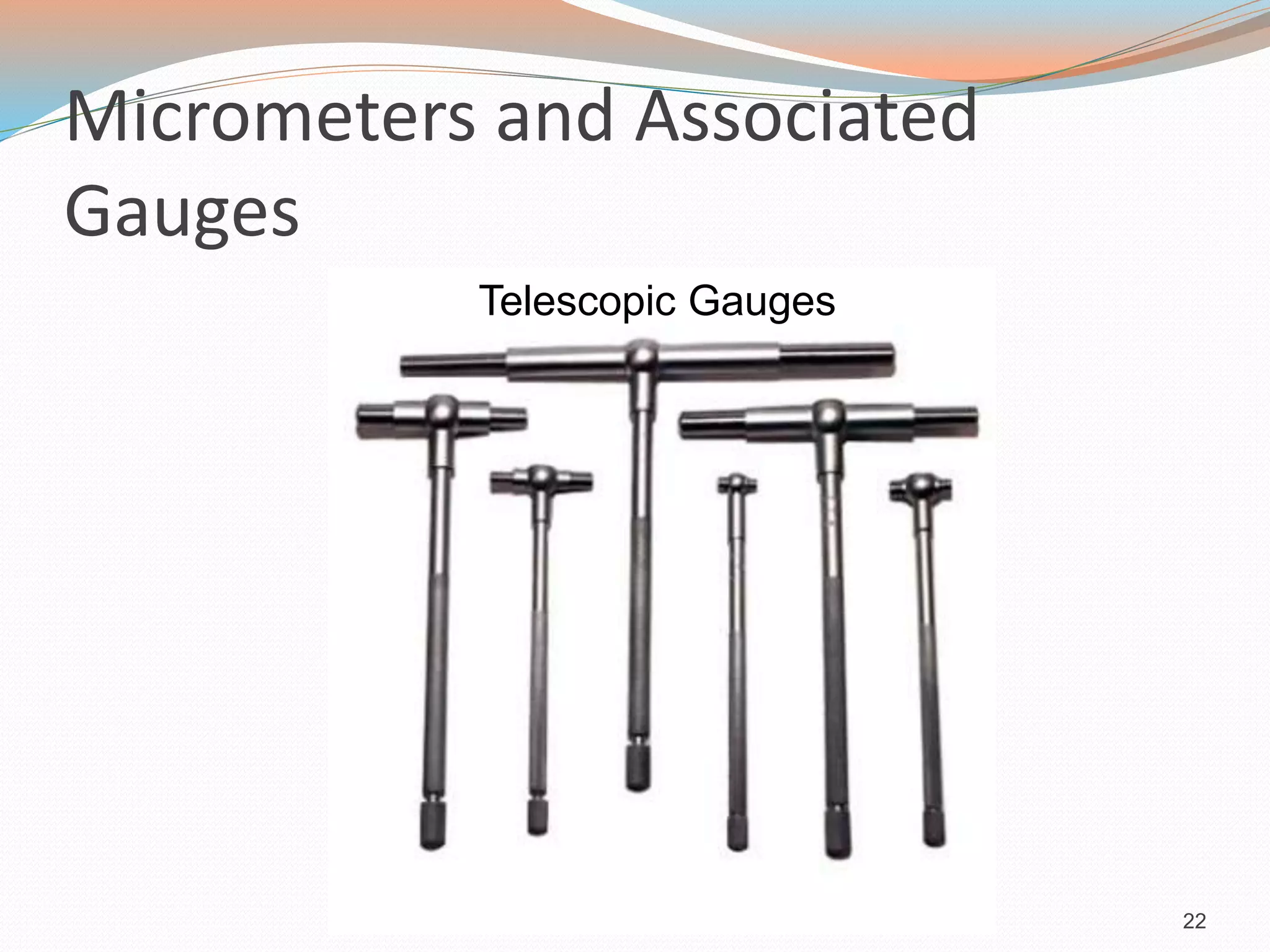

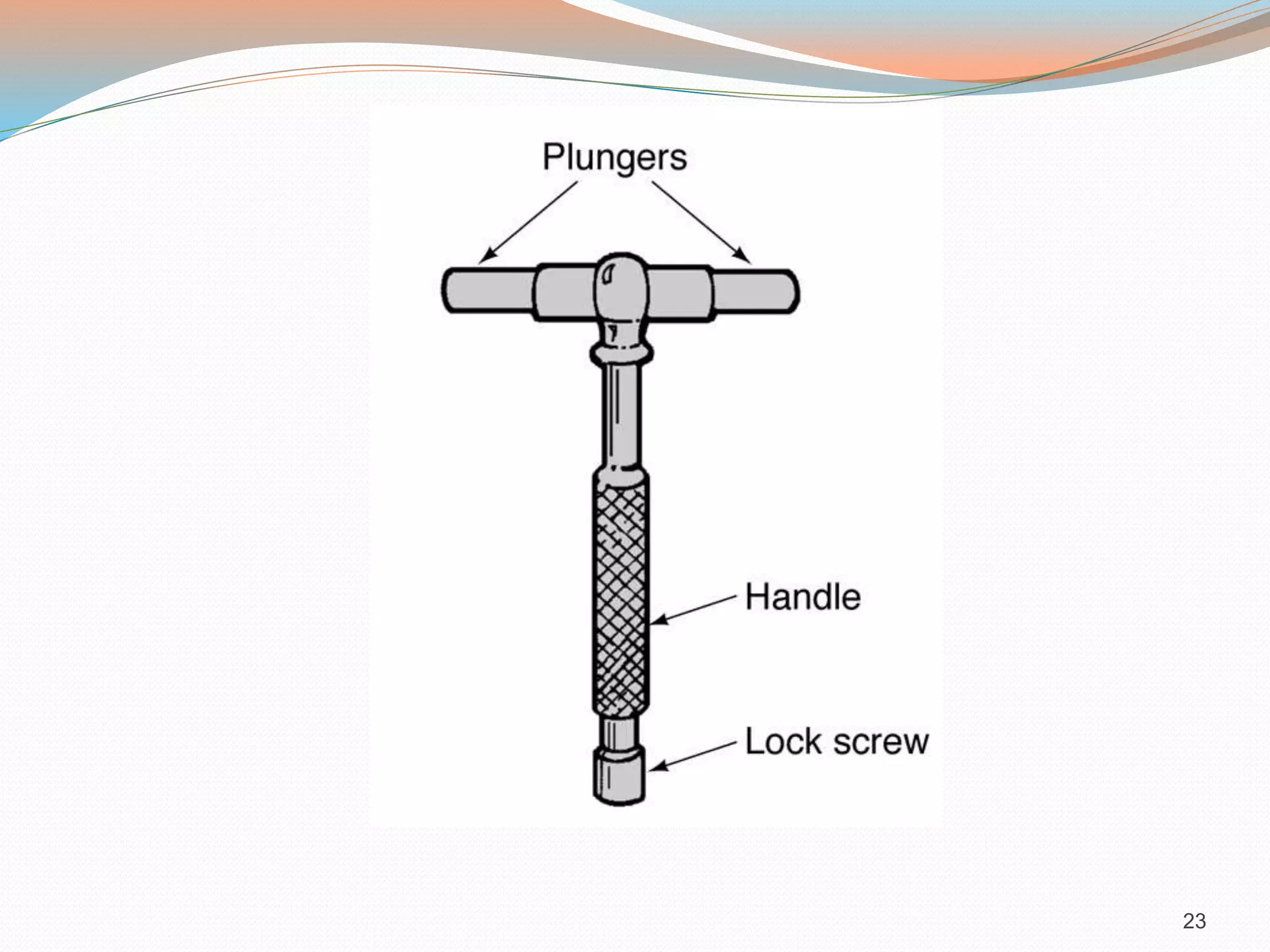

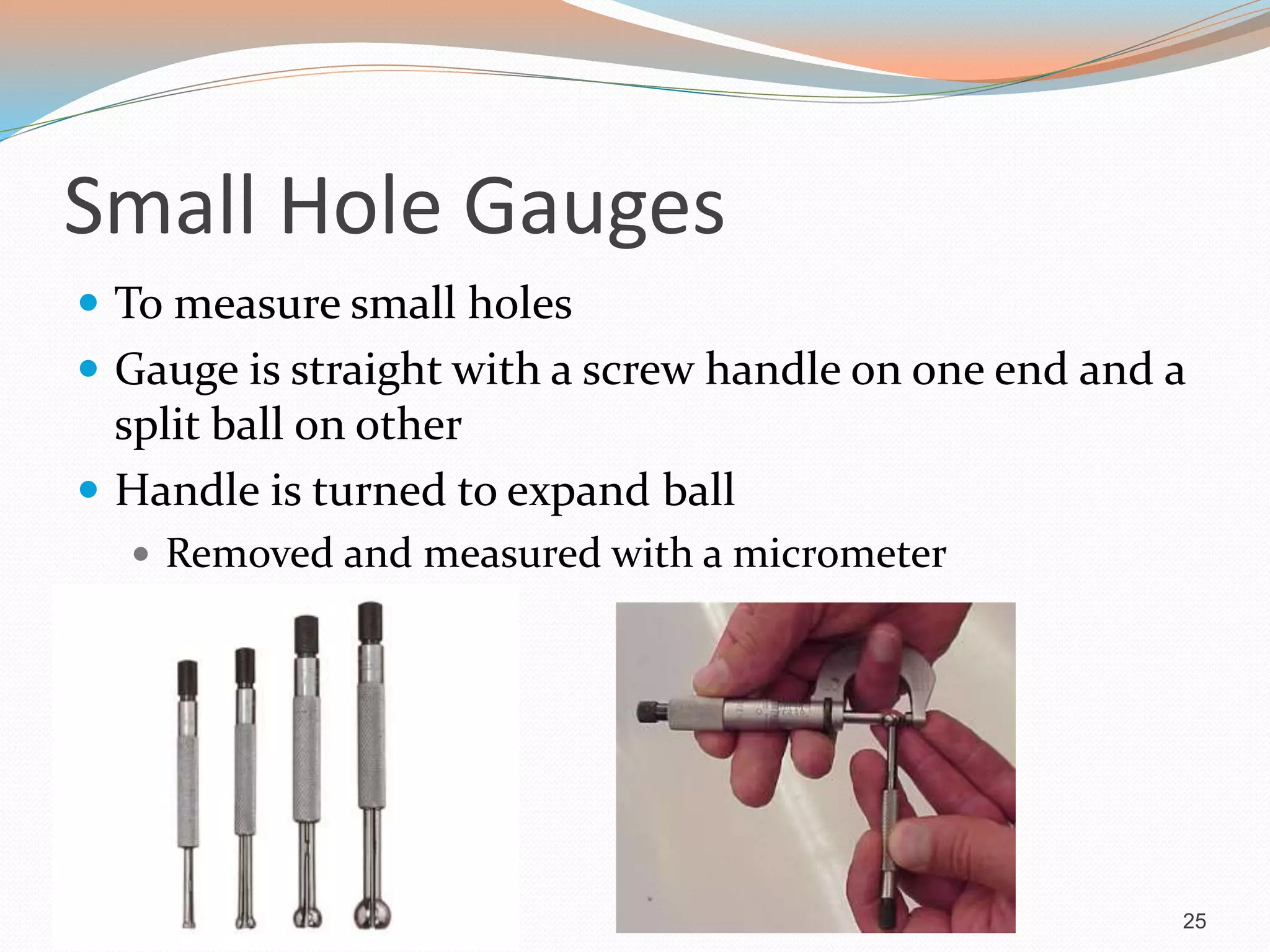

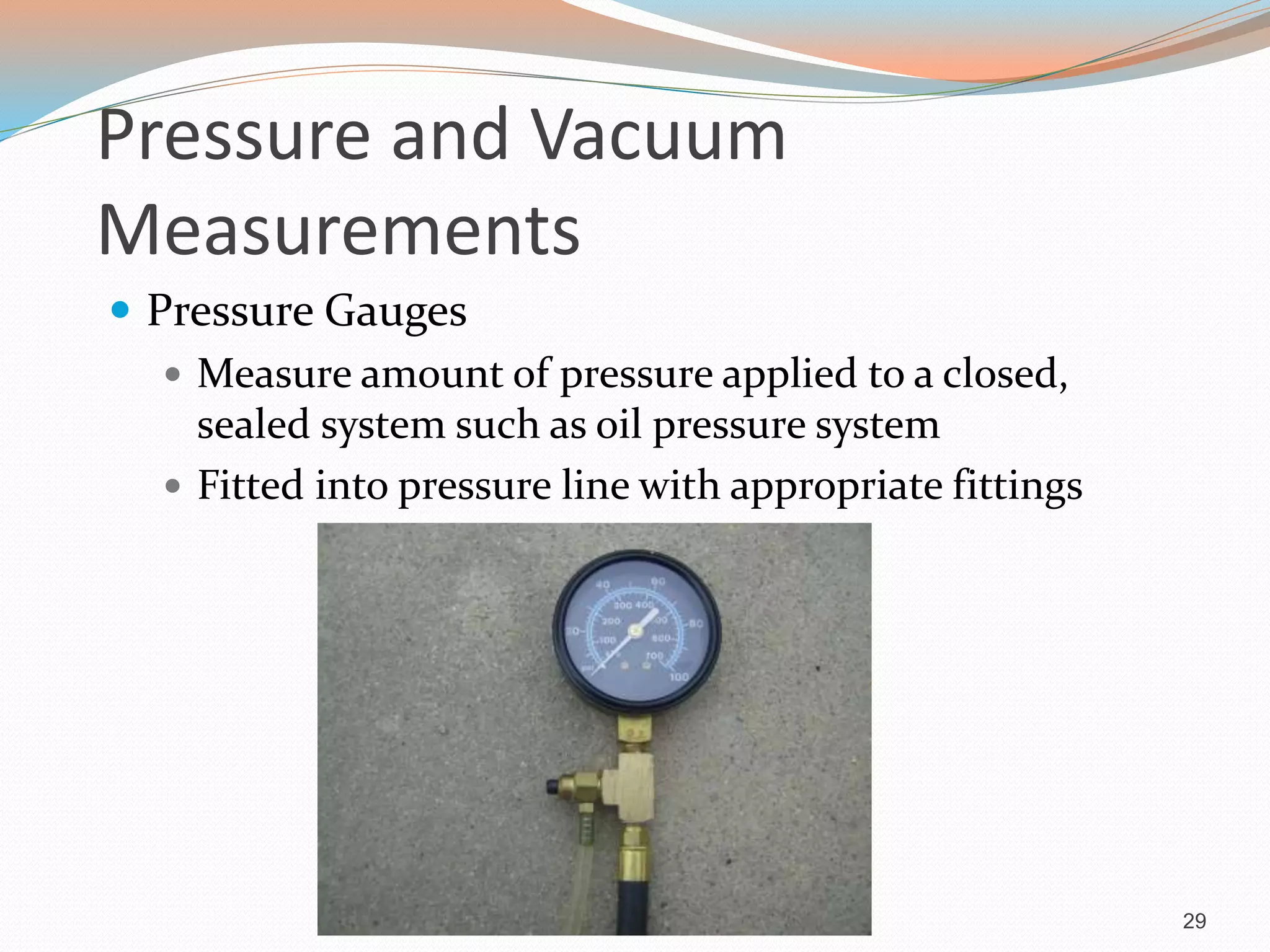

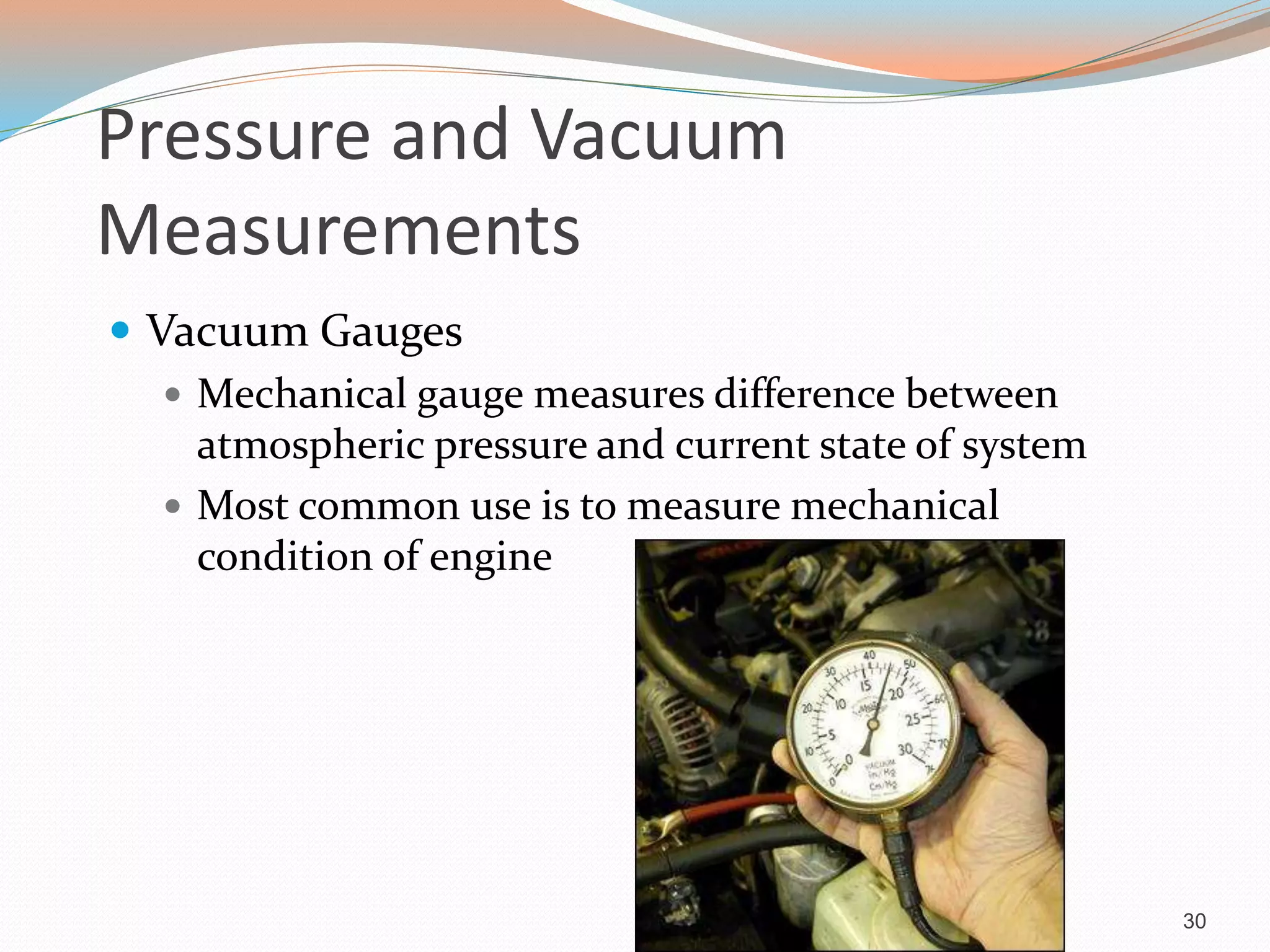

This document discusses various measurement devices and systems used in automotive repair. It describes the United States Customary and metric measurement systems, with the inch and meter as their base units respectively. It provides details on common measurement tools like rulers, feeler gauges, micrometers, dial indicators, calipers, and gauges for measuring pressure and vacuum. Proper tool selection and technique are emphasized for obtaining accurate measurements.