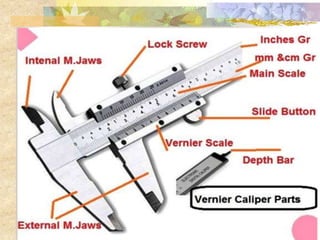

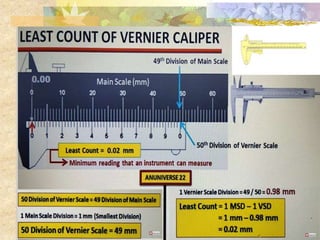

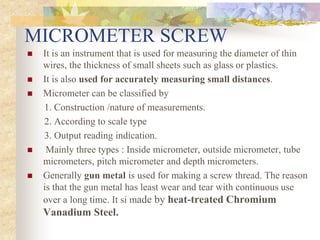

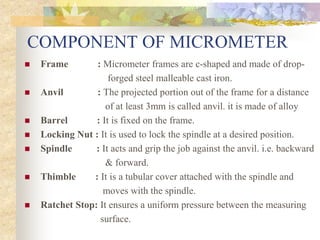

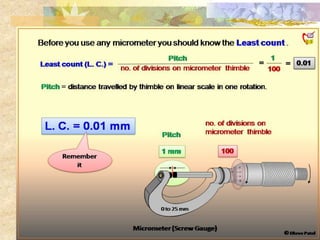

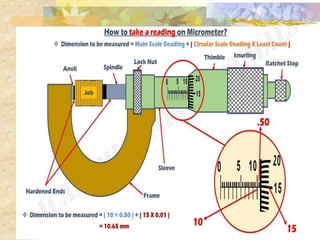

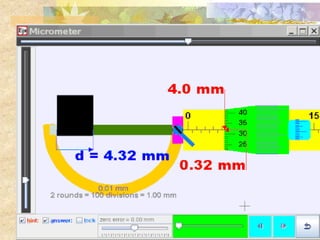

The document details precision instruments used for exact measurements, focusing primarily on vernier calipers and micrometers. It explains their components, measurement capabilities, reading techniques, and classifications based on standard specifications. Both instruments are essential for measuring physical dimensions with high accuracy, featuring parts like jaws, scales, and locking mechanisms.