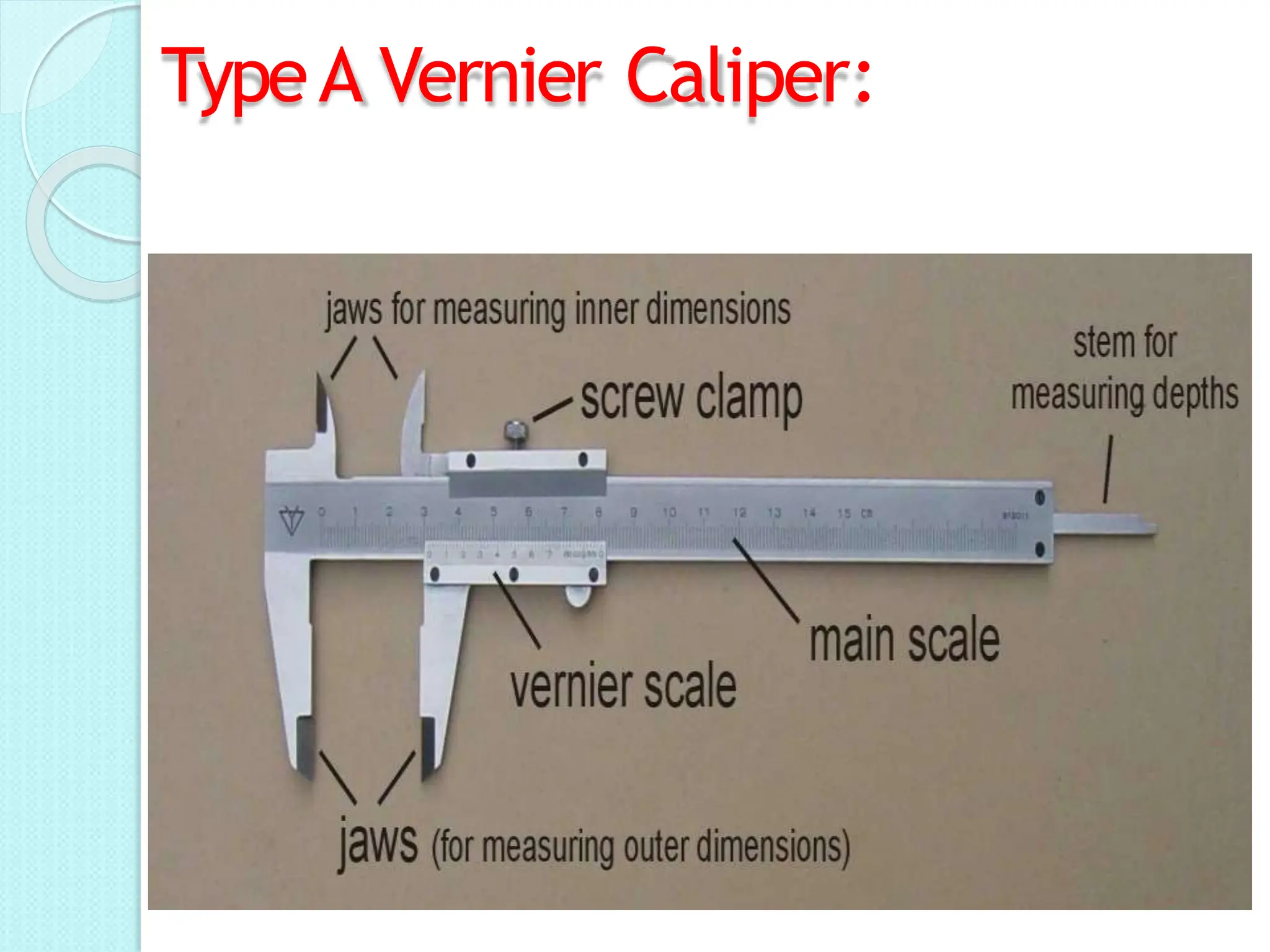

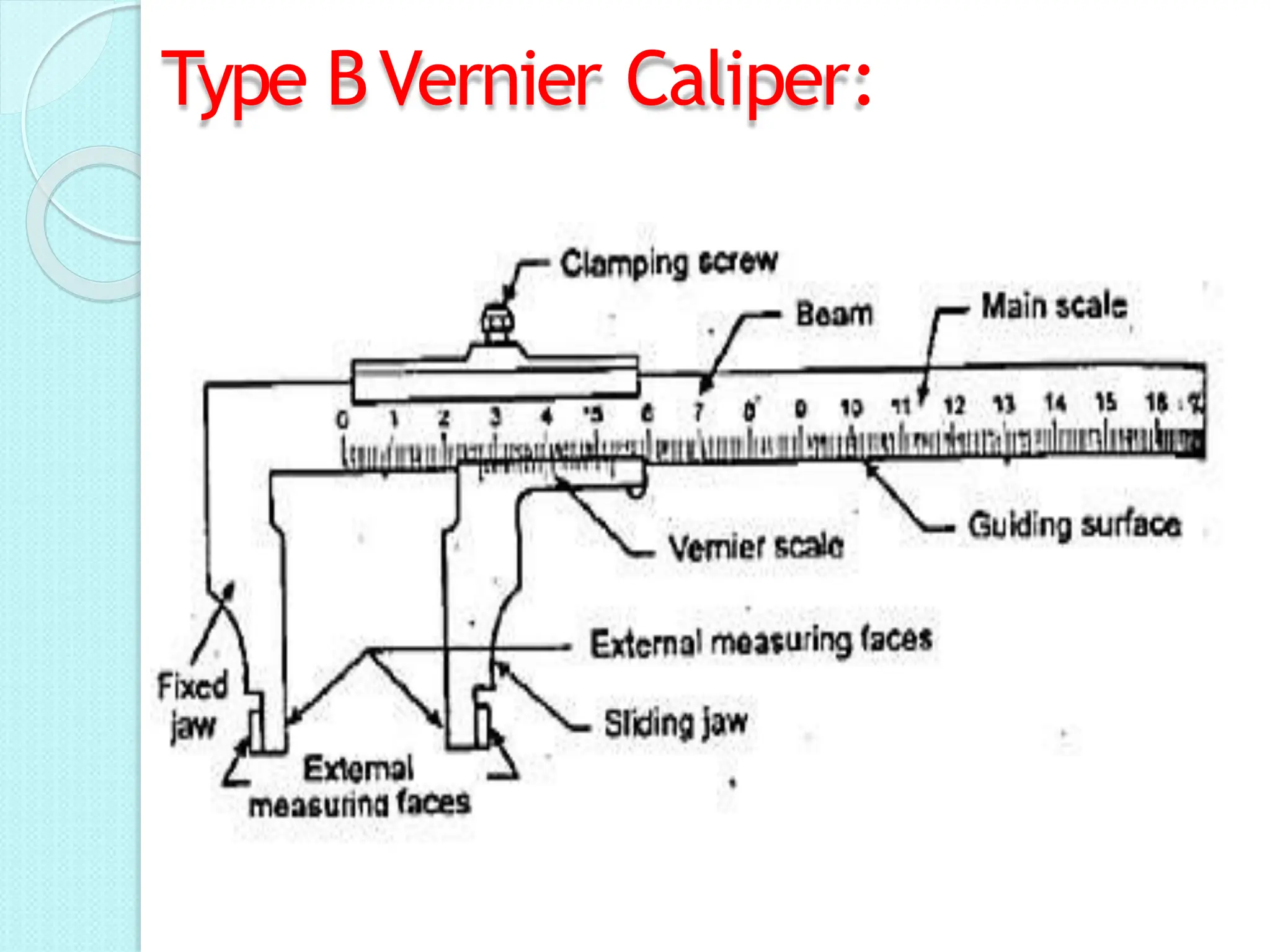

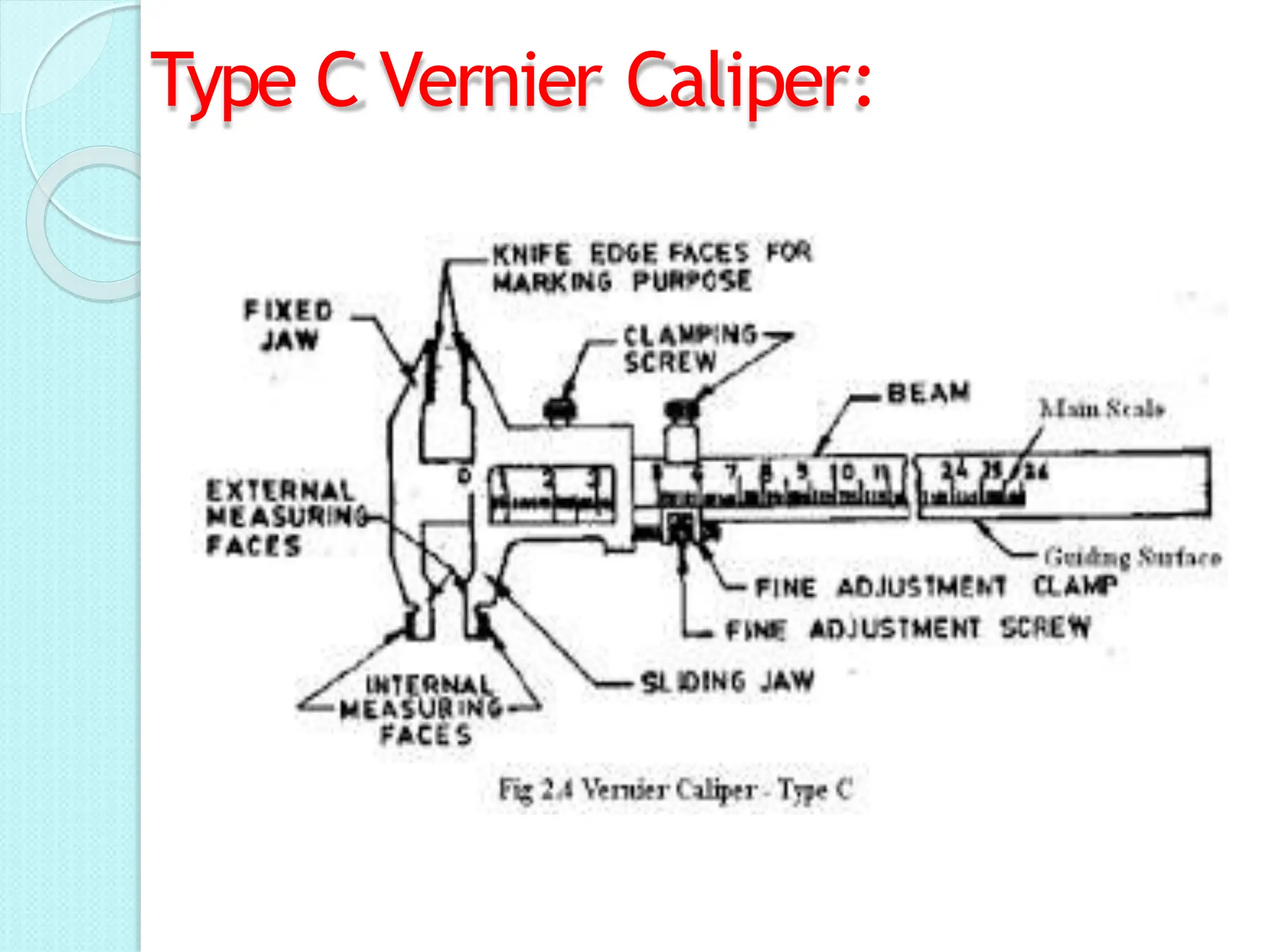

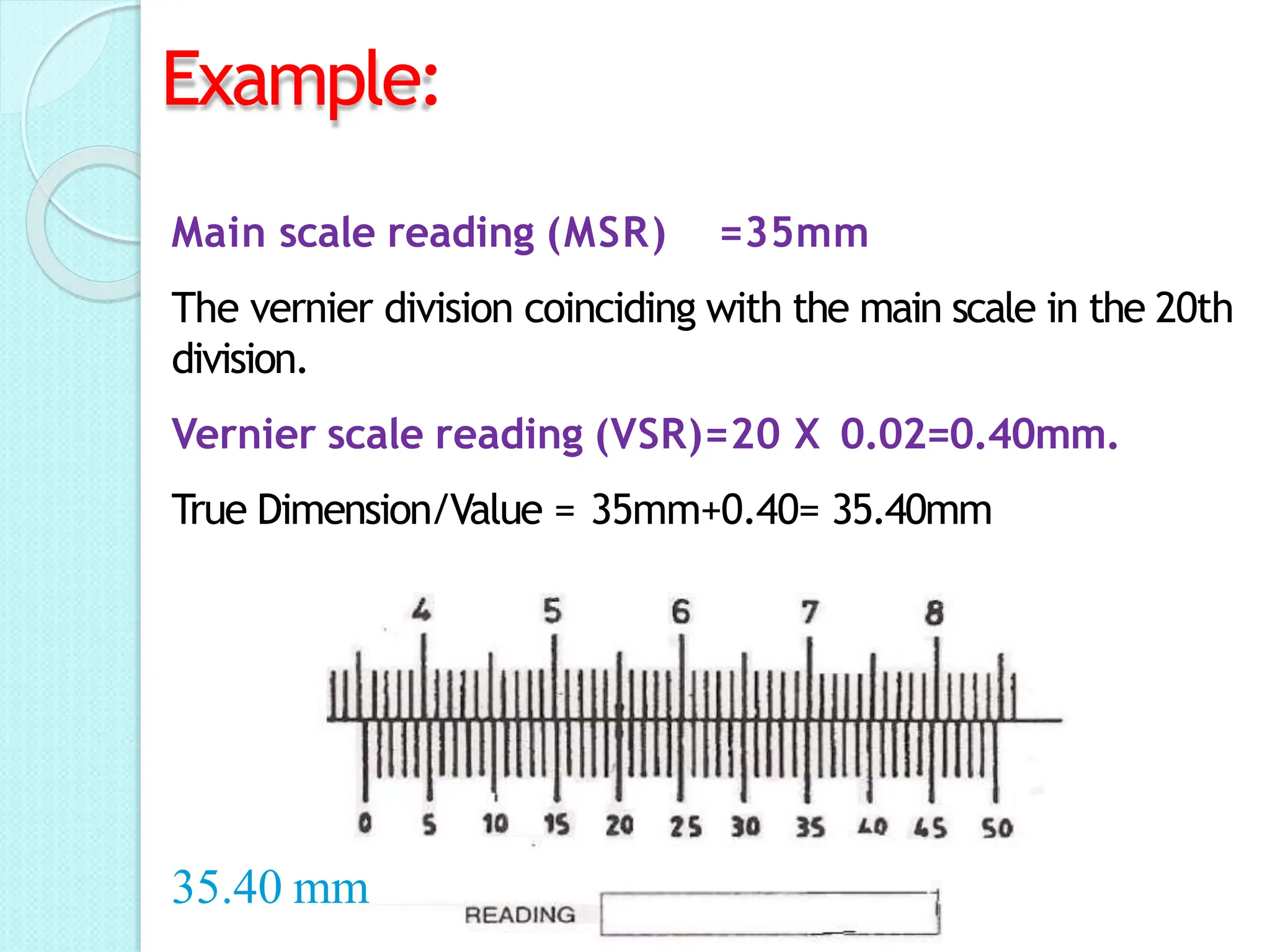

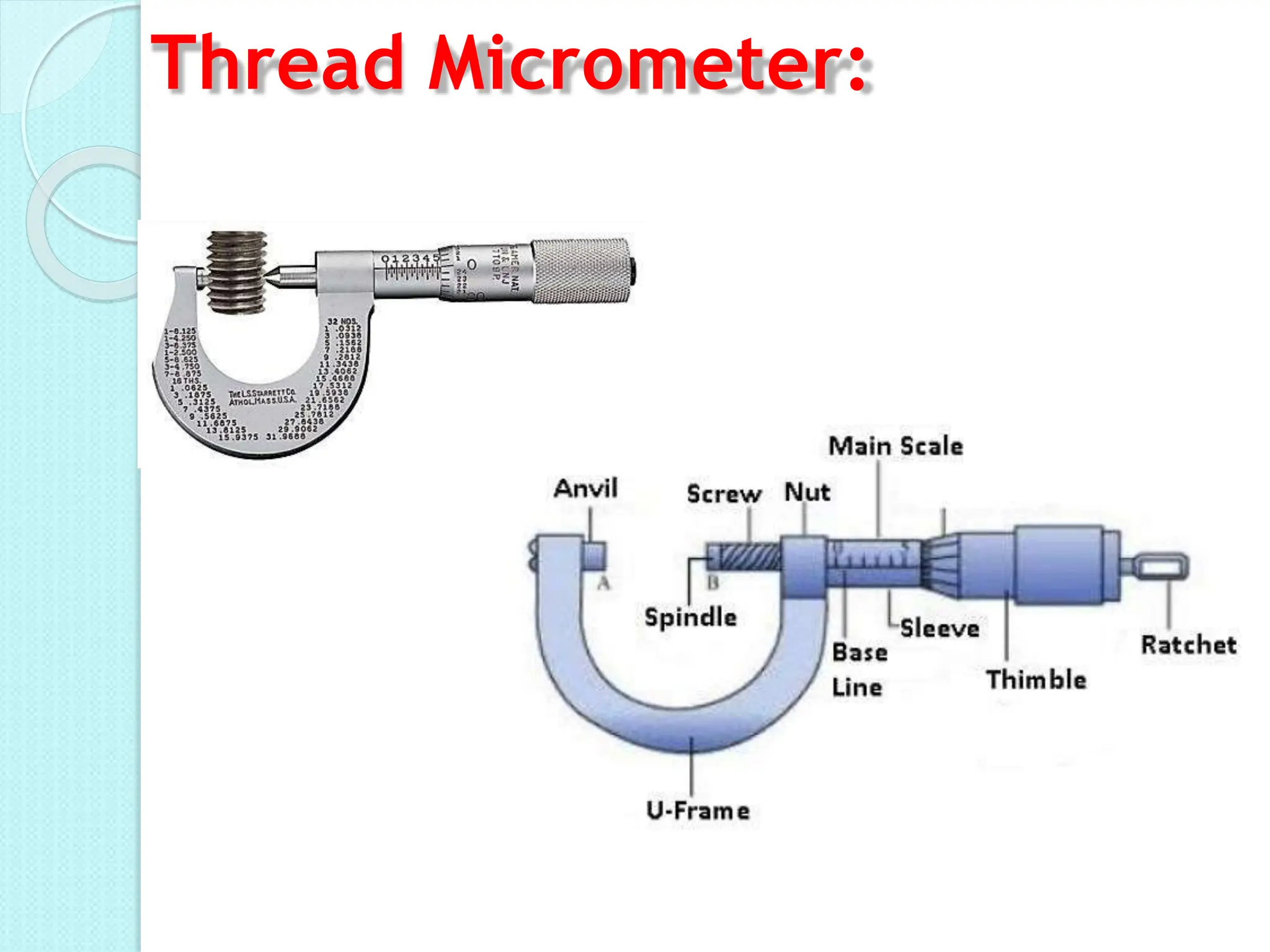

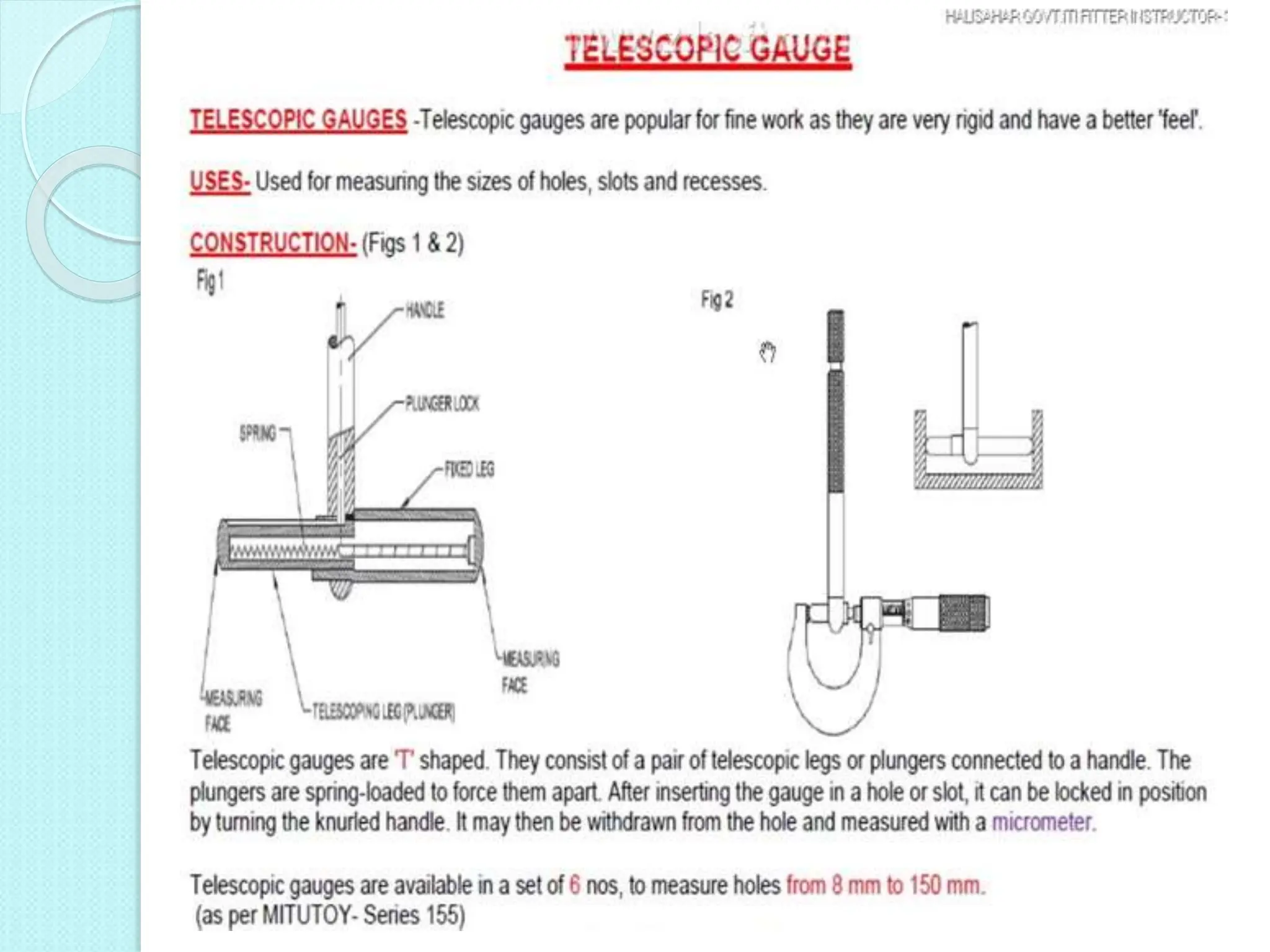

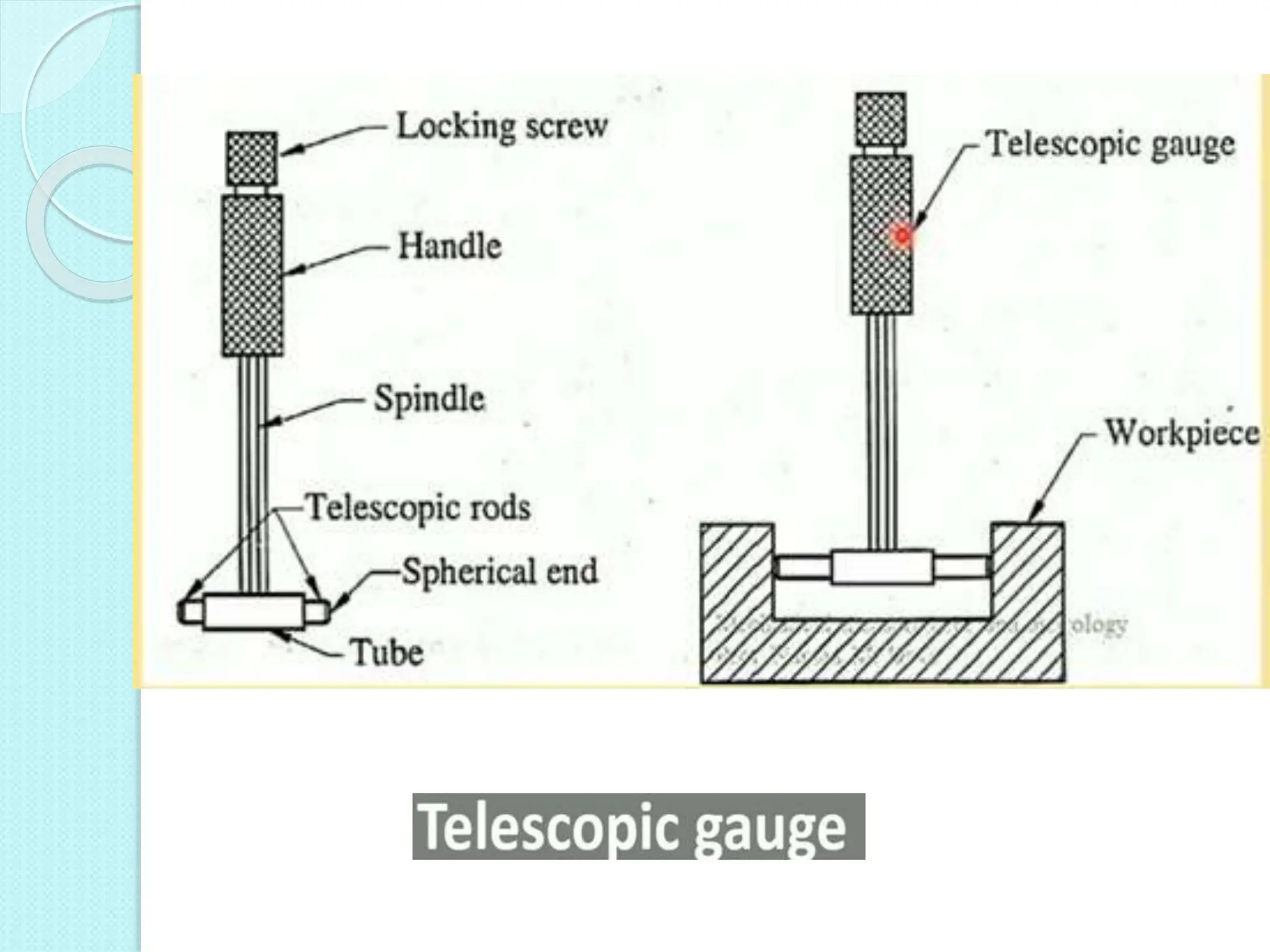

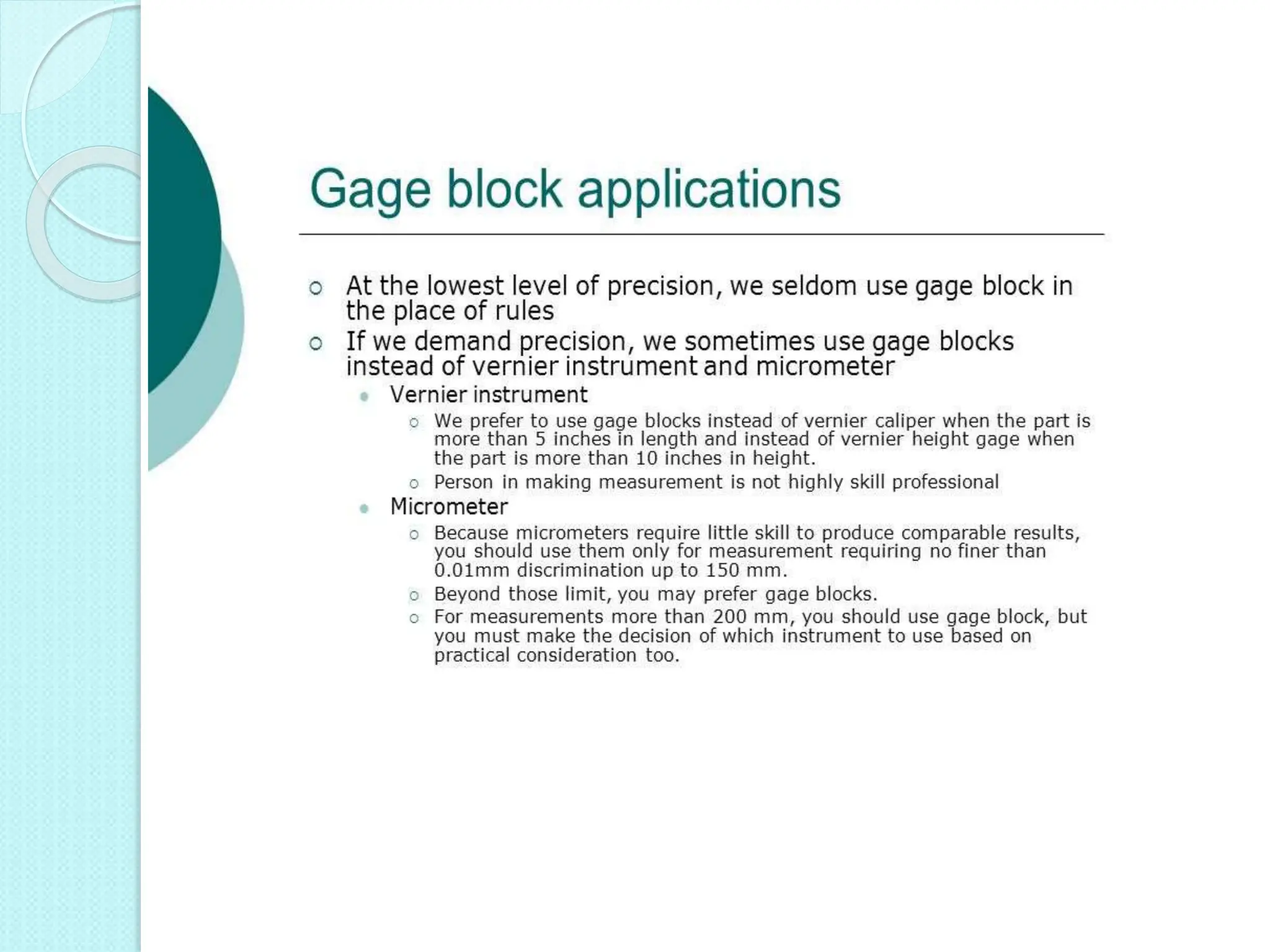

The document discusses various linear and angular measurement instruments. It describes different types of linear measurement devices including vernier calipers, micrometers, gauge blocks, and comparators. It also covers angular measurement tools such as bevel protractors, universal bevel protectors, clinometers, and angle gauges. The document provides details on the components, use, and reading of key linear and angular measuring instruments.