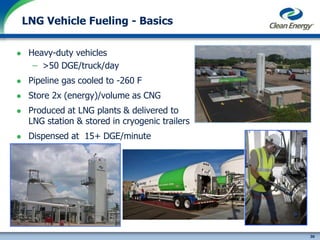

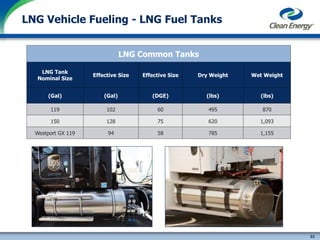

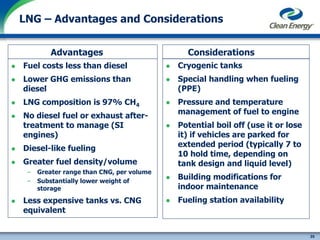

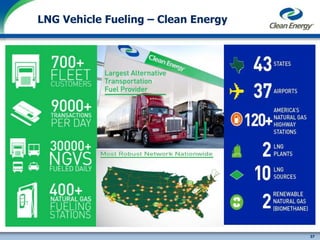

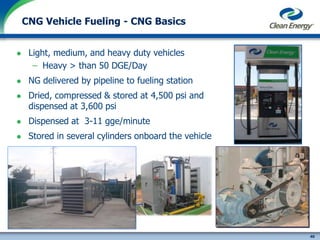

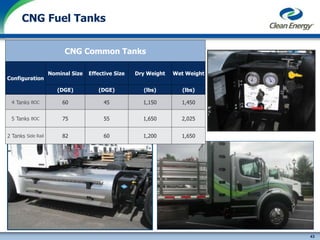

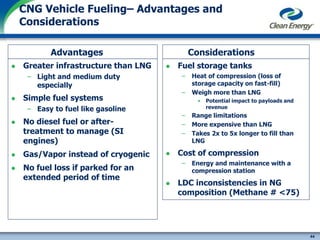

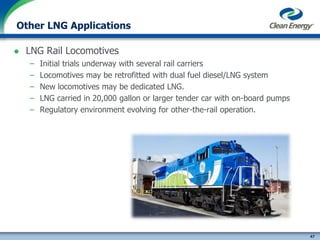

The document provides an overview of LNG technology, focusing on its cooling, storage, and fueling for vehicles, presented by IMW Industries and Clean Energy Fuels Corp. Key topics include the basics of LNG, LNG station and fueling technology, safety precautions, and comparison with CNG fueling. The document also discusses various applications of LNG in transportation and the advantages and considerations of using LNG versus CNG.