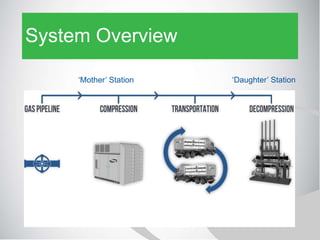

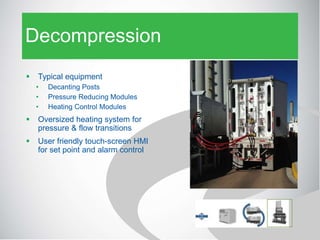

The document outlines the operation and advantages of Clean Energy Compression's CNG delivery systems, highlighting the roles of mother and daughter stations, compressor technology, and efficient gas transportation methods. It emphasizes the exclusive competitive advantages of their non-lubricated compressors, which reduce oil carry-over, lower operating costs, and offer scalability and reliability for various applications. Clean Energy Compression is positioned as a leading supplier in the CNG market, providing a range of services and equipment while being a subsidiary of Clean Energy Fuels Corp.