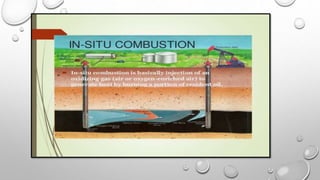

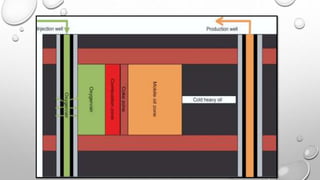

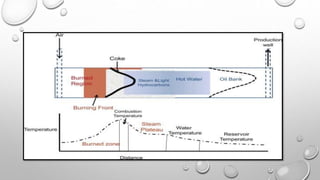

This power point presentation summarizes in-situ combustion, specifically the air requirements. It introduces in-situ combustion as a thermal recovery method that generates a fire underground using injected oxygen. It then describes the key techniques as including gas drive, water drive, forward and reverse processes. The methods are defined as dry combustion using only air and wet combustion combining water and air injection. Characteristics of suitable reservoirs are identified as having permeability over 100md, porosity, thickness over 10ft and depth sufficient to confine injected air. The conclusion restates that in-situ combustion aims to recover hydrocarbons via combustion with no depth limit impacting injection pressure.