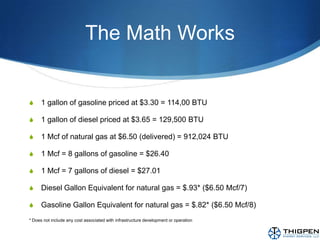

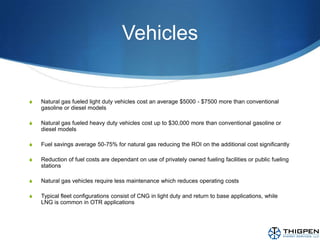

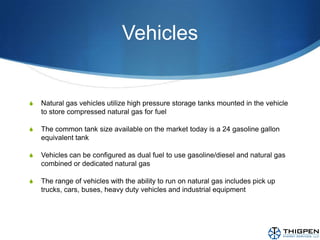

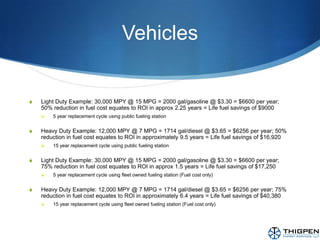

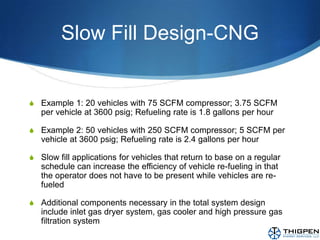

The document discusses the rise of the natural gas vehicle (NGV) industry, highlighting the economic advantages of utilizing natural gas over petroleum, including significant cost reductions and lower emissions. It details the infrastructure for compressed and liquefied natural gas, emphasizing efficient fueling systems and the reliability of natural gas supplies. Furthermore, it promotes the role of companies like Thigpen Energy Services in expanding NGV infrastructure to support this growing market in the United States.