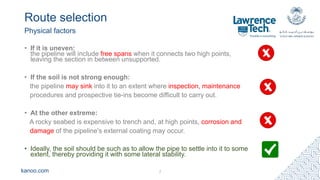

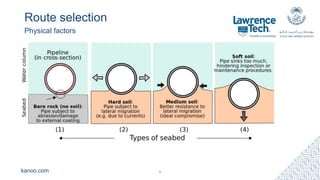

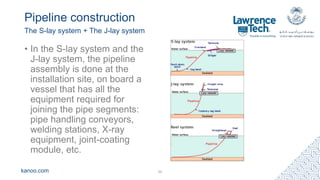

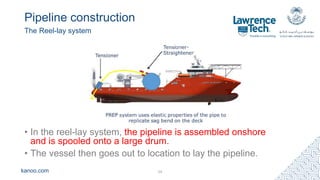

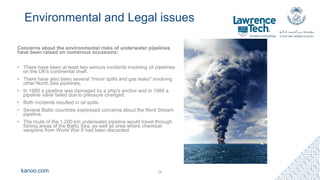

The document discusses offshore pipeline operations, highlighting important factors such as route selection, submarine pipeline characteristics, construction methods, and environmental/legal issues. It details consideration of seabed conditions and the design of pipelines for different environmental conditions, including construction techniques like s-lay, j-lay, and reel-lay systems. Additionally, it addresses environmental risks and concerns related to underwater pipelines, reflecting on past incidents and the potential impact on marine areas.