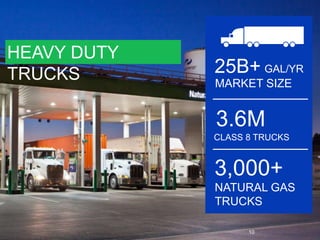

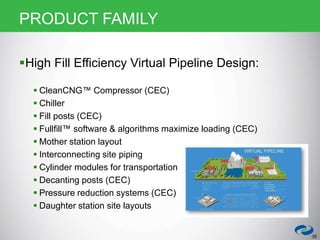

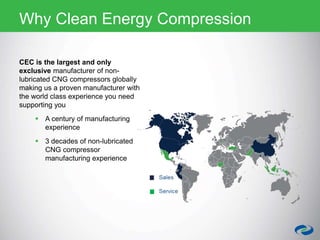

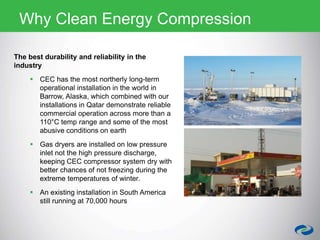

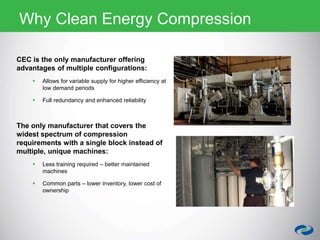

The document highlights the benefits and applications of natural gas as a fuel source, emphasizing its cost savings, environmental advantages, and increasing adoption globally. It outlines Clean Energy Compression's history, market position as a leading provider of natural gas fueling solutions, and details on their technological innovations and product offerings. Additionally, the document discusses various sectors utilizing natural gas, such as transportation and industrial applications, alongside the company's commitment to quality engineering and customer service.