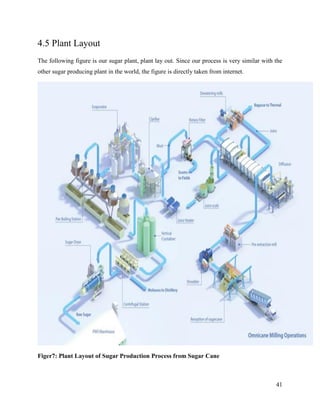

The document is a final project report on unbleached sugar production from sugar cane, detailing its design and economic evaluation. It outlines the project's objectives, methodologies, and financial projections, concluding that the planned sugar plant is technically feasible and financially viable, with a projected annual output of 21,154 tons and a payback period of 2 years. The research emphasizes the growing domestic demand for sugar in Ethiopia and the potential to help bridge the demand-supply gap.

![33

Q2= m *moisture content of sugar * [607 + 0.3 ×T1 –T0]

m= amount of sugar to be dried = 0.82kg/s

M = moisture content of sugar *m = 0.25403kg/s

Thus Q2= 0.25403kg/s * [607 + 0.3 ×50 –30] = 654.03kw

Total energy on drier = Q1+Q2 = 781.03kw

Table8: Summary of calculation result on heat/energy balance

Units Steam/vapor flow rate

kg/s

Energy required kw Annual steam

requirement Mw

Heaters 0.636 1434.83 43045

Evaporators 3.95 152.08 4562.4

Crystallizers 0.502 29.5 885

Drier 781.03 23431

Total 2379.5 71923.4](https://image.slidesharecdn.com/materialbalance2017-170615161317/85/Material-balance-2017-33-320.jpg)

![34

3.3 Equipment Sizing and Specification

3.3.1 Heaters

We know from heat transfer principle that the size of the heat exchanger is proportional to Q, log

mean temperature and heat transfer coefficient.

A =Q/(U*∆TLM), we have assumed that in the previous calculation the steam used is as saturated

steam at 1bar and 100 0

C. And the juice enter the heater at 30 and exit at 96 0

C. From literature

heat transfer coefficient for this types of fluid are ranged between 2271.32 –5678.3 W/ (m2.

K) and

the average value is assumed. U=3975 W/ (m2.

K), the log mean temperature calculated as follow:

∆Tlm= [(100 - 30) - (100 - 96)]/ [ln {(100 - 30)/ (100 - 96)}] =53.1k and Q from the above

calculation 1434.83kw. Thus

Total heat transfer area = A = Q/ (U × ∆Tlm) = (1435×1000w)/ (3975 W/ (m2.

K) *53k) = 6.81m2

3.3.2 Mixed Juice Storage Tank(s)

Here we calculate the size of tanks that used in storing mixed juice from mills as primary and

secondary before it sent to the clarifier unit and the pump capacity is also calculated. The maximum

allowable retention time in the tank is 30 min, above this time limit conversion of sucrose to simple

sugar is started which is undesired.

The density of mixed juice from mills (Hugot) ranges from 1.07 – 1.09 kg/dm2

. Assume that the

density = 1.08kg/dm2

= 1080kg/m3

. Thus

Volume flow rate of juice = mass flow rate/density of mixed juice = (20.5ton/hr.)/1080kg/m3

=

19m3

/hr. This also the pump capacity (456m3

/day) and the pump is centrifugal pump. Tank volume

(V=19m3

/2 = 9.5m3

)](https://image.slidesharecdn.com/materialbalance2017-170615161317/85/Material-balance-2017-34-320.jpg)